Virtual prototyping in Linux with examples

It so happened that Linux for me is a home system for more than 5 years. I own various CAD systems under Windows and perfectly see the abyss that exists in this area. But regardless of the chosen OC, there is no such tool “to make beautifully” - pressed the cherished button and the idea was embodied in a suitable 3D model / drawing. Designing a very long comprehensive process, from stages to testing samples. And all the means are good here, from simple pencil and paper, plasticine boxes to heaped CAD systems with weight calculations and other buns. The process in Windows looks the same and you also have to constantly use “bundles” of different software for a single prototype, but the cost of this software for hobbies, to put it mildly, is very high.

In this case, it will be a hobby, albeit a profitable one, but still a hobby. I will talk about the software needed to create real prototypes that I use for Debian testing with DE xfce. My choice may not be perfect, but it is quite good for creativity.

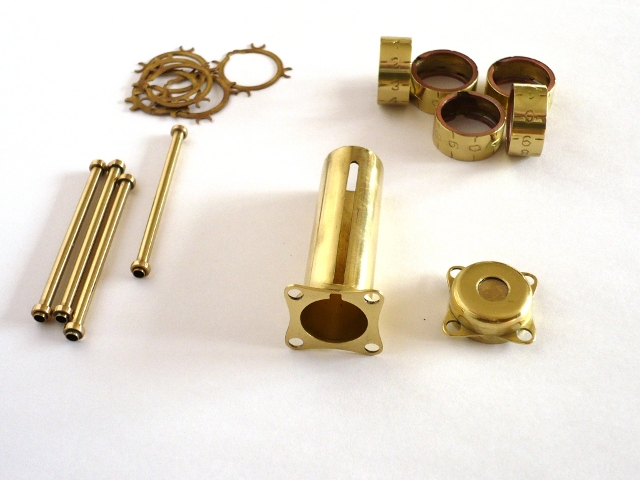

So, there is a certain idea in vacuum, it is necessary to find a tool for 3D visualization with the possibility of rapid prototyping by means of CNC.

')

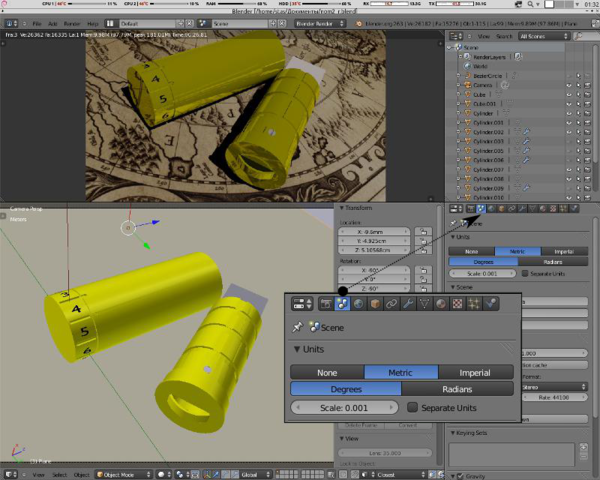

Blender

Perhaps the best tool for visualization, even out of the box, is significantly superior to the capabilities of many CAD visualization modules.

Practically without dances, it allows to “digest” the model into clear CNC g-code, and this is understandable, because with exports to .stl there are fewer questions.

For an engineer accustomed to the metric system and measuring everything in millimeters, it will only be necessary to set the usual measurement system:

Result:

Pros:

- photo realistic render

- animation, will fit as a means for moving parts

- the presence of a video editor, as a means for the presentation of ideas

- the possibility of obtaining G-code for CNC

Minuses:

- it is often elementary difficult to estimate the dimensions of the parts, and the model should contain as much information about itself.

- poorly predictable import / export formats. in spite of the existence of a small group of converter plug-ins, the main problem is the translation of the source files into the formats needed by the engineer. So also in terms of geometry: often the dimensions “float”, the curvature of lines is distorted, etc.

Video:

However, Blender is still not CAD, although there have been attempts to make one of it, for example, the blenderCAD plugin. But the originally incorporated polygonal modeling mechanism is not very suitable for advanced CAD systems with a solid modeling mechanism.

However, for homework “on the knee”, usually a blender is more than enough, because design documentation is often simply superfluous, it’s enough to understand how to turn an idea into an acceptable shell. But often, own skill is not enough or easier to give some parts to an outsourcing, and when working with contractors de facto need a system that works perfectly with DWG or DXF. Turning / milling "exhaust" with Blendera also not offer because you will go not only the forest but also on foot. Sometimes you just need the tools to create documentation and transfer it in print.

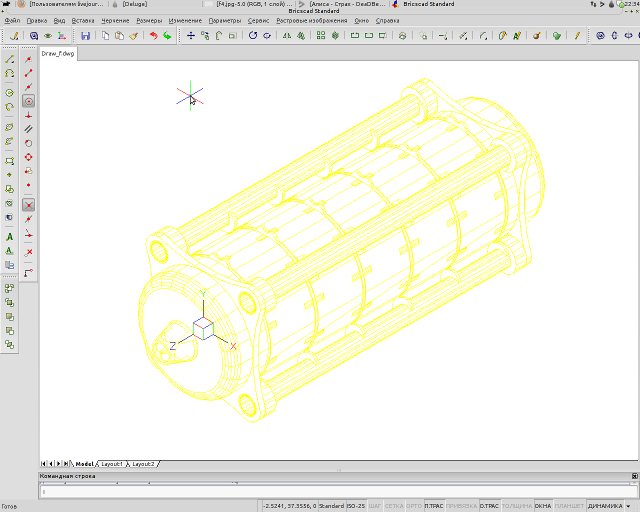

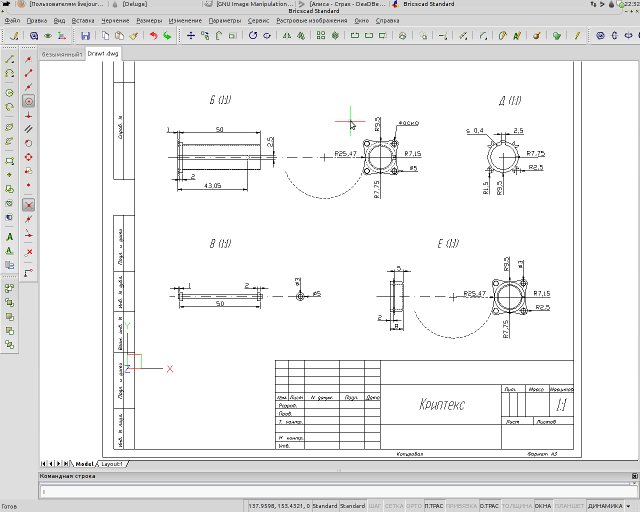

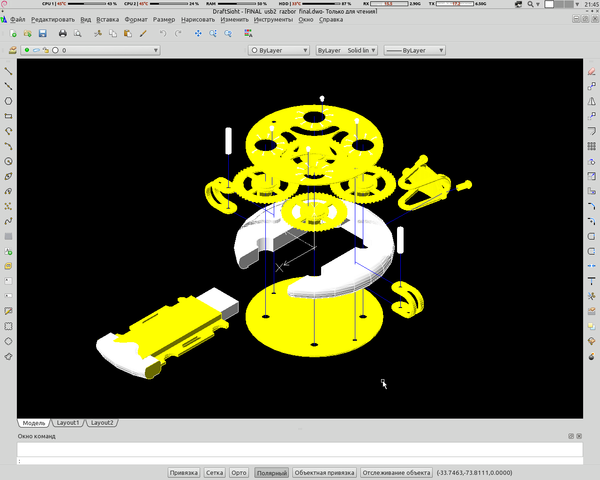

Bricscad

The most user-friendly tool for solid-state 3D modeling (Solid modeling) under Linux is positioned as an analogue of AutoCad, although it does not reach that level. When working in 2D (drawings, reamers, etc) is almost as good as AutoCad.

Result:

Pros:

- full compatibility of output files with AutoCad

- predictable import / export

- ability to convert drawings / models into pdf

Minuses:

- proprietary software is also a paid one, however, a free license for a year is available for students.

DraftSight

Before exploring Bricscad, he was the main tool for working with DWG. Allows you to create, edit and view DWG files, but alas, 2D. 3D can be viewed, but no more.

Due to the complete migration to Bricscad, the tool is no longer relevant.

Result:

Video:

Incscape

For creativity “on the knee,” the tool is fully capable of replacing Windows analogs of vector editors, such as CorelDraw. An indispensable thing when working with scans for Blender. But for the most part I use to receive paper prints on laser irons technology.

Pros:

- not bad binding system

- export to DXF

Minuses:

- there is no "usual" drawing engineer teams

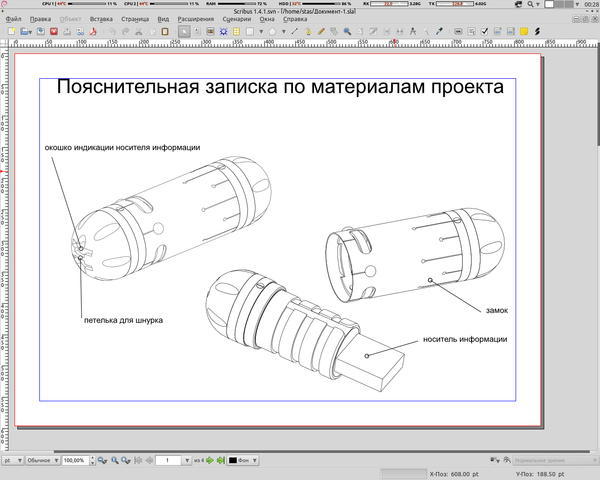

Scribus

Tool for the layout of documents. For its main purpose - the transfer of documentation in electronic form in PDF format or a paper printout copes completely.

Cons not seen.

Here perhaps all the necessary set of software for visualizing ideas. It remains only to get the simplest tool from the pantry and make it, even if not in the pictures. Design initially saves time and materials for a lot of ideas, but time is short. With the demand for the idea and the corresponding conversion into banknotes, again, nothing prevents to do everything on the CNC. Fortunately, this software allows you to create 2D and 3D models.

However, CAM systems and software for controlling CNC machines is a topic for a separate article ...

Source: https://habr.com/ru/post/159953/

All Articles