Green Data Center cooling system with 85% energy savings!

During the construction of the Time Data Center, we had to study a huge number of cooling systems. Among them was a system that really liked. We want to share information about the newfangled cooling system of Data Centers.

Here is a schematic depiction of this system:

The image is a normal chiller, then a frikulling module. But then comes the LPS system (leakage prevention system), which we will describe below.

')

Further, through the copper tubes, the liquid enters the server cabinets!

To be more precise, the liquid enters the special rear doors for server cabinets. These doors are suitable for various third-party cabinets and also have various modifications, at least: 48U 42U, 600mm and 800mm.

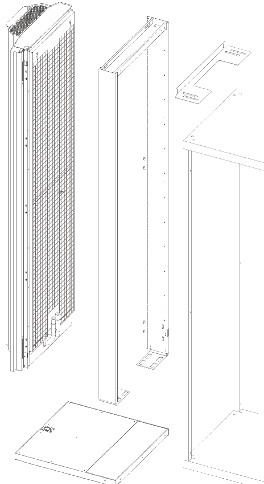

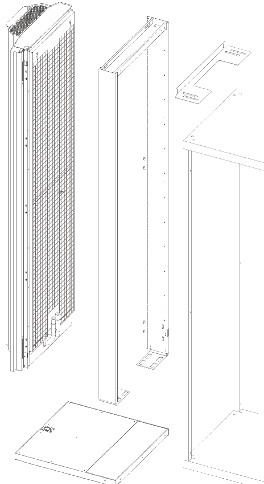

Here is the mounting scheme for such doors:

Note the advantages of this system:

And now the fun part. LPS system to prevent leaks. Developed by the supplier of these systems, www.aquacooling.co.uk and the University of Cambridge. The information on her work is zero.

But as dealers of these systems told us, it works according to the law of Bernoulli / Venturi.

We wondered how this system still works.

Here is the law itself, provided that the difference in the height of the location of the pipes can be neglected:

All further calculations with a large error, since the friction force is not taken into account and we take an ideal incompressible fluid.

Take the density of the liquid for 0,998 g / cm3. This is with rounding of 1000 kg / m3 (thanks vmarunin for the amendment)

Further, the pressure we must have is not less than atmospheric. Therefore, 760 mm. Hg Art. = 100kPa

From here it can be calculated that the speed will be about 14 m / s

Further, there is again to take an ideal incompressible fluid, then the law will act: v1S1 = v2S2

Where one of the speeds will be 14m / c, well, let's take a section of the tube, say for 2cm2. Then, when the tube section is 4 cm2, the speed will be 7m / s

Well, in conclusion, I would like to say that 100kPa (atmospheric pressure) is about 1 bar, and modern pumps pump up to 8 bar and more.

Thus, the section inside the door is most likely smaller than the section suitable for the cabinets, which makes it possible inside the tube to be sure that small holes will not cause harm.

Also, speed / pressure sensors are provided for entry and exit of doors, which allows to increase the pressure in the system at the right moment, which will create a negative local pressure.

Unfortunately, there was not enough karma to write to the hub "Cooling Systems"

Here is a schematic depiction of this system:

The image is a normal chiller, then a frikulling module. But then comes the LPS system (leakage prevention system), which we will describe below.

')

Further, through the copper tubes, the liquid enters the server cabinets!

To be more precise, the liquid enters the special rear doors for server cabinets. These doors are suitable for various third-party cabinets and also have various modifications, at least: 48U 42U, 600mm and 800mm.

Here is the mounting scheme for such doors:

Note the advantages of this system:

- Energy saving - no cold dissipation on the way to the consumer

- Uniform cooling

- High equipment density - up to 25kW from the cabinet

- Saving space, since the cabinet can be clogged tightly and there is no precision air conditioning inside the containment area

LPS - Leak Prevention System

And now the fun part. LPS system to prevent leaks. Developed by the supplier of these systems, www.aquacooling.co.uk and the University of Cambridge. The information on her work is zero.

But as dealers of these systems told us, it works according to the law of Bernoulli / Venturi.

We wondered how this system still works.

Here is the law itself, provided that the difference in the height of the location of the pipes can be neglected:

All further calculations with a large error, since the friction force is not taken into account and we take an ideal incompressible fluid.

Take the density of the liquid for 0,998 g / cm3. This is with rounding of 1000 kg / m3 (thanks vmarunin for the amendment)

Further, the pressure we must have is not less than atmospheric. Therefore, 760 mm. Hg Art. = 100kPa

From here it can be calculated that the speed will be about 14 m / s

Further, there is again to take an ideal incompressible fluid, then the law will act: v1S1 = v2S2

Where one of the speeds will be 14m / c, well, let's take a section of the tube, say for 2cm2. Then, when the tube section is 4 cm2, the speed will be 7m / s

Well, in conclusion, I would like to say that 100kPa (atmospheric pressure) is about 1 bar, and modern pumps pump up to 8 bar and more.

Thus, the section inside the door is most likely smaller than the section suitable for the cabinets, which makes it possible inside the tube to be sure that small holes will not cause harm.

Also, speed / pressure sensors are provided for entry and exit of doors, which allows to increase the pressure in the system at the right moment, which will create a negative local pressure.

Unfortunately, there was not enough karma to write to the hub "Cooling Systems"

Source: https://habr.com/ru/post/159555/

All Articles