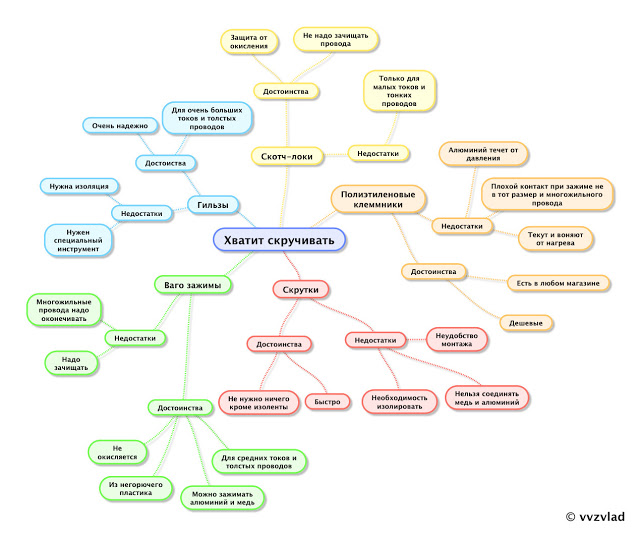

Stop twisting!

Well, really, stop. There are a lot of cool pieces for connecting a wide variety of wires, but still the technology “bite off the insulation with your teeth, twist it, roll it up with tape” is still alive.

About normal wiring

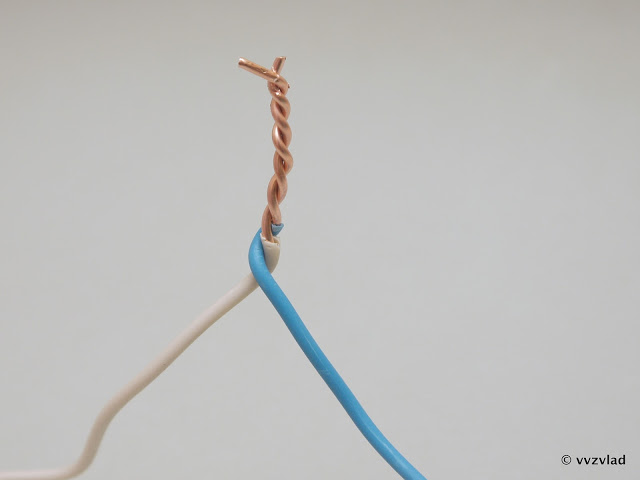

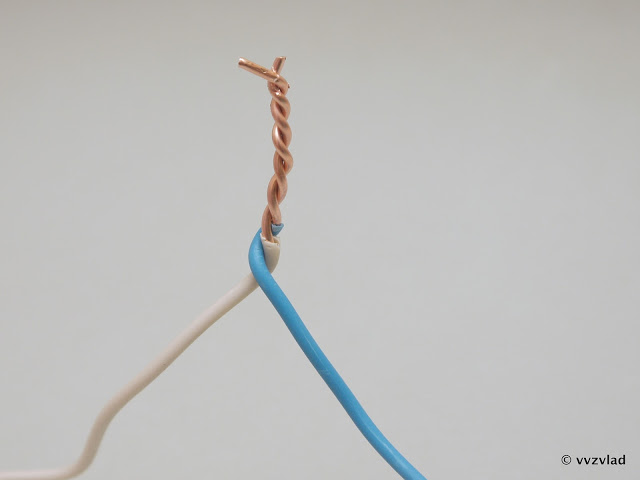

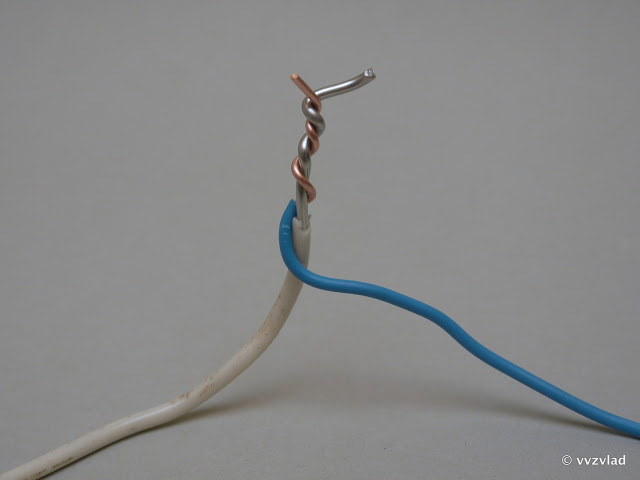

When I see this, I feel uncomfortable:

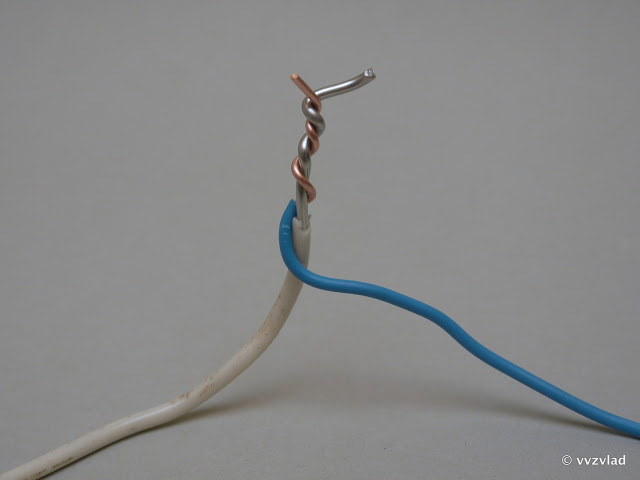

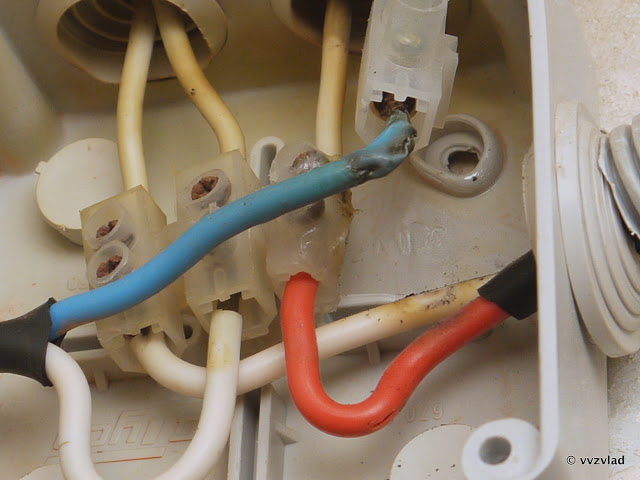

And when I see this, I want to kill the author:

The fact is that you can not twist copper and aluminum wires in any way.

There are several reasons for this. The main problem is the oxidation of aluminum wire in contact with copper - a galvanic pair is formed, which slowly but surely destroys the connection. And the faster, the greater the current through this twist goes.

Of course, in a couple of hours, such a connection will not fall apart, even if a heater or a kettle is turned on through it. But over time, the resistance will slowly increase, because of which the twist will warm up stronger and stronger. And if the load is not constant, but episodic, then constant heating-cooling cycles will worsen the conductivity even more. When heated, different materials expand in different ways, and switching on and off of the load through such a twist will be equivalent to constant twitching it back and forth. You understand that it will not lead to anything good.

Well, if just heating, it can usually be traced by the characteristic smell of burning insulation. But the arcing of the compound, especially near the wallpaper or something flammable, can easily turn into a fire.

What solutions exist to solve this problem?

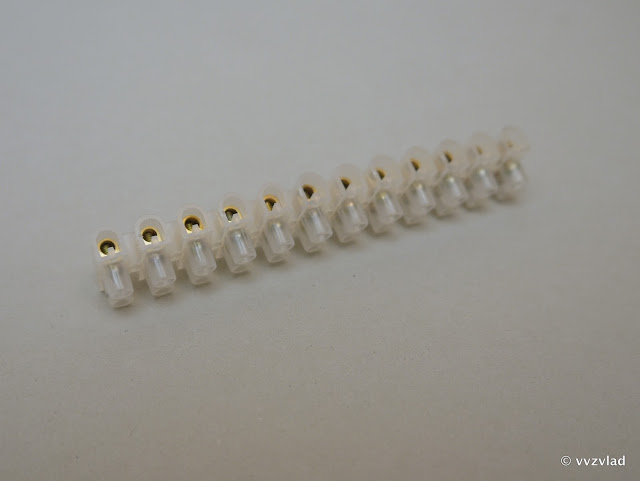

Sold in any hardware store, worth a penny.

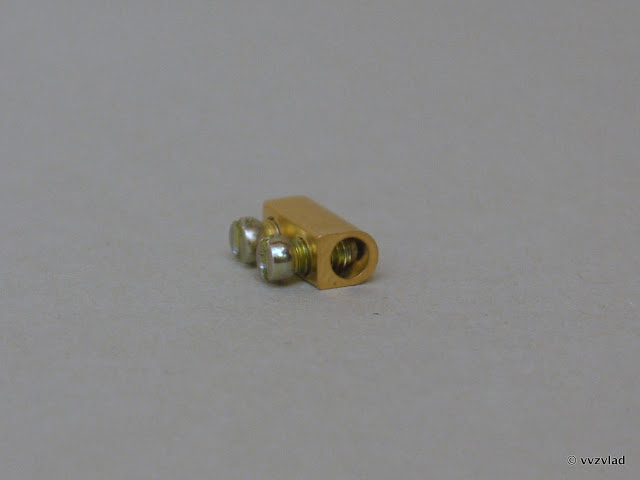

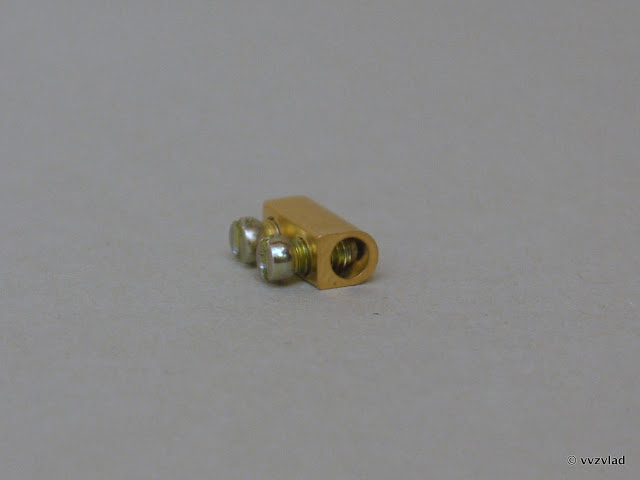

Inside here is a brass sleeve with two screws:

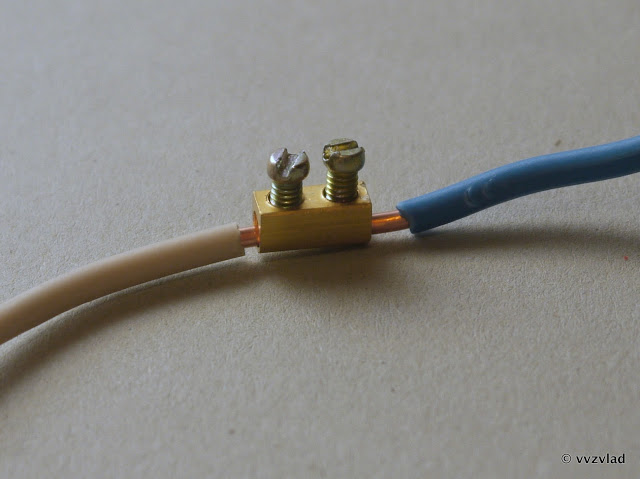

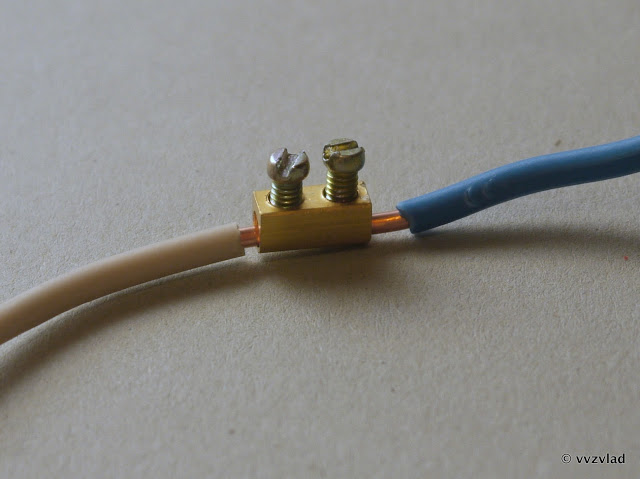

We push wires into it, we clamp with screws:

<

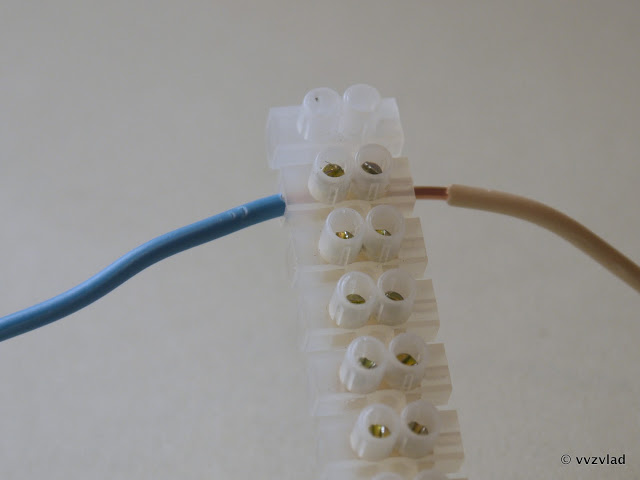

I specifically pulled it out for clarity. Together with isolation, it will look like this:

Each segment can be cut off. It would seem ideal. But there is a nuance (s)

Although these nuances and shortcomings - the car and a small truck, do not be fooled by the simplicity.

It is generally advisable not to use such terminal blocks. If you use, then only with single-conductor wires and for connecting something small - a light bulb, a fan (not industrial). And no aluminum!

It is also advisable not to buy noname China, but the terminals of normal manufacturers: Tridonic, ABB, Legrand, Believes

Cost: from 10 to 50 rubles.

Solid black plastic pads. Already better.

Have a removable cover:

And here is the internal structure:

Turn off, thrust the wire, clamp.

Pros - clamps, not a screw, but a metal plate. We press to the bottom steel plate. In addition, the upper part is not flat, but with a characteristic surface that increases the surface of the clamp:

.

.

Due to this, you can clamp the stranded and aluminum wires. Aluminum, however, it is desirable to at least sometimes check for loosening clamping. I saw the pads on currents 25A and 40A.

The inconvenience is not cut and does not divide, either buy a bunch of small ones (I have not seen less than 6 pieces), or even put one big one on two wires.

Cost: from 30 to 80 rubles.

')

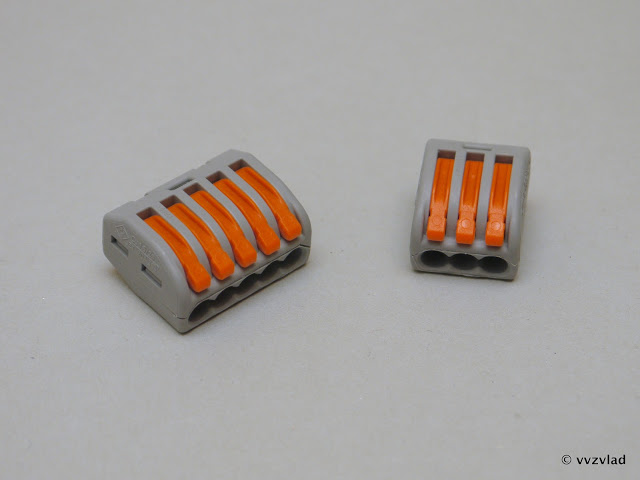

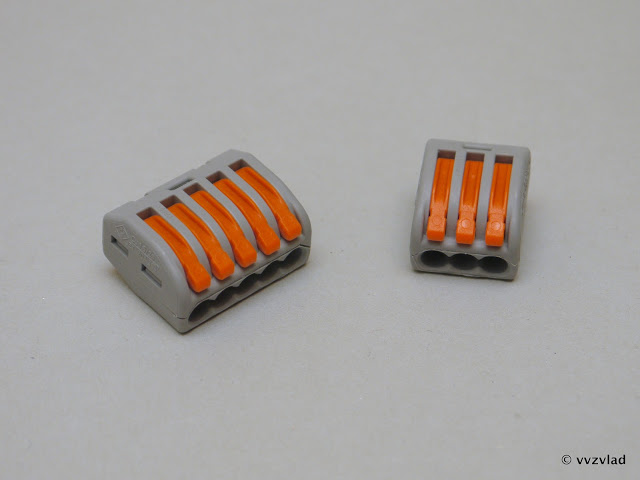

Self-tightening terminals (WAGO or REXANT series 773 and their copies)

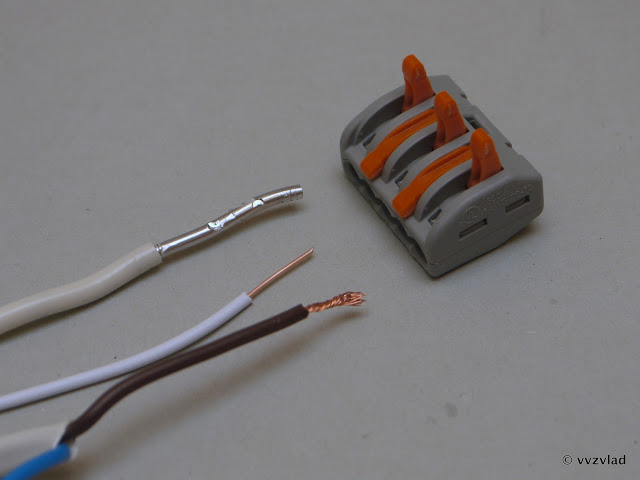

Or they are also called express terminals. Like these ones:

Very handy stuff. Cleared the wire, put it in to the end, ready:

<

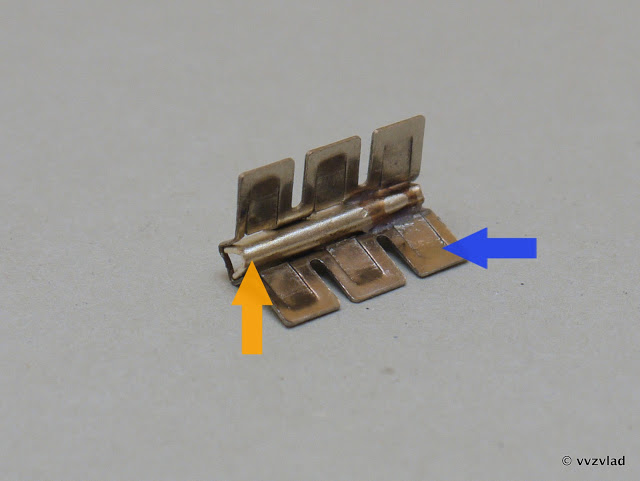

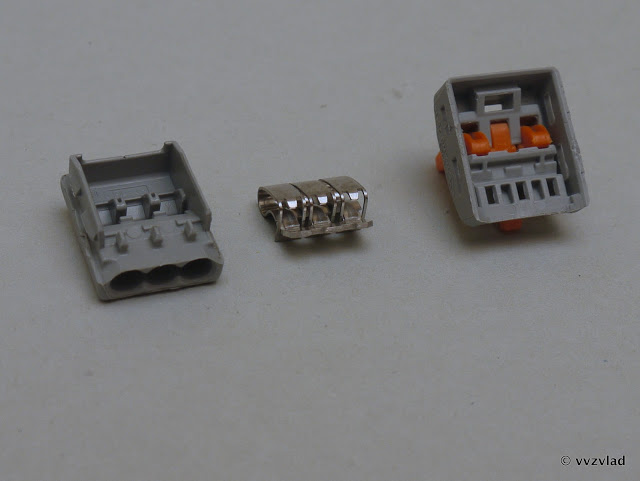

Inside there is a pressure plate (blue arrow) and a small bob (orange) made of tinned copper:

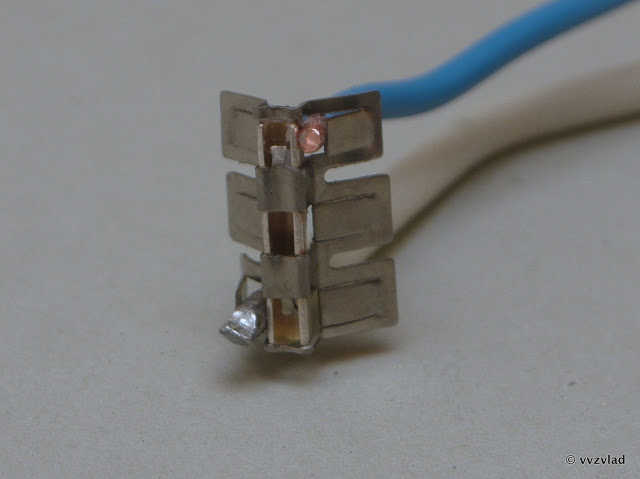

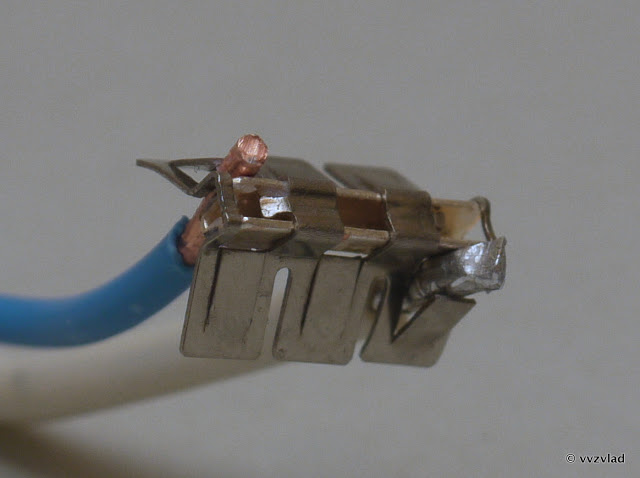

When wires are stuffed into it, what happens is:

The plate presses the wire to the tavern, keeping the pressure all the time. And the design of the pressing part on gives the wire to fall. You can hardly get him out. In general, they are disposable, but if you really want, then you can gently rotate the wire around its axis.

Since the copper contact is tinned, you can insert aluminum wire into such a terminal without fear of problems. At the same time, constant pressure will not allow the aluminum wire to fall out.

The white paste (on the next photo you can see the white mass on the contact) is quartz sand with technical petroleum jelly, especially for aluminum wires. Quartz sand is an abrasive that clears the oxide film from the surface of aluminum, and petroleum jelly does not allow it to form again.

The same terminals, but transparent:

They are no different than the dye. Well, in transparent terminals it is more convenient to see the wire - they are pushed to the end or not.

Plastic - non-flammable, melts with increasing temperature, without emitting harmful substances into the air.

Designed for 25 A, and this is about 4 KW. Attention! Currents are indicated for original WAGO terminals only.

Terminals Rexant (manufacturer - VTS groups), use another spring steel, which relaxes when heated. Accordingly, the maximum current is limited, except in lighting is not recommended.

Here is a test in which they kept 50A and did not even melt. Well, it is in ideal conditions - in the air, the cooling was good. And the original terminals, yes.

Cost: from 2 to 6 rubles, depending on the number of contacts

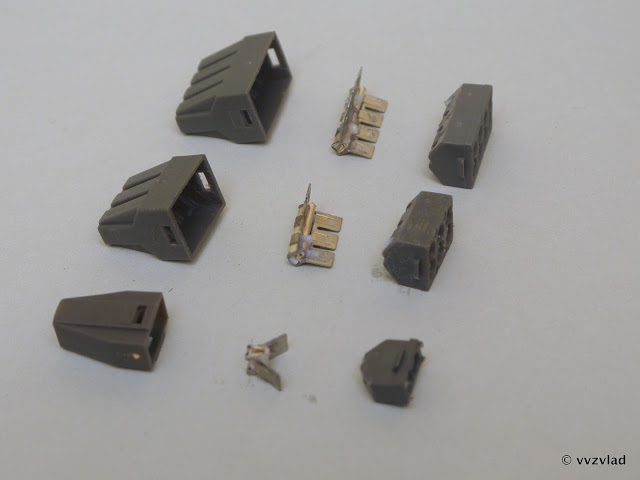

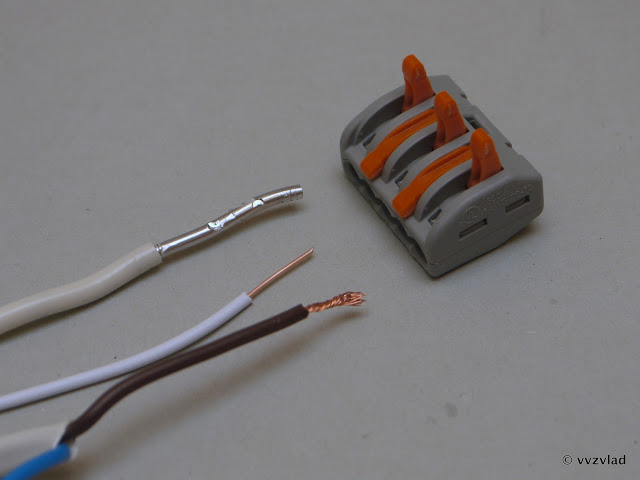

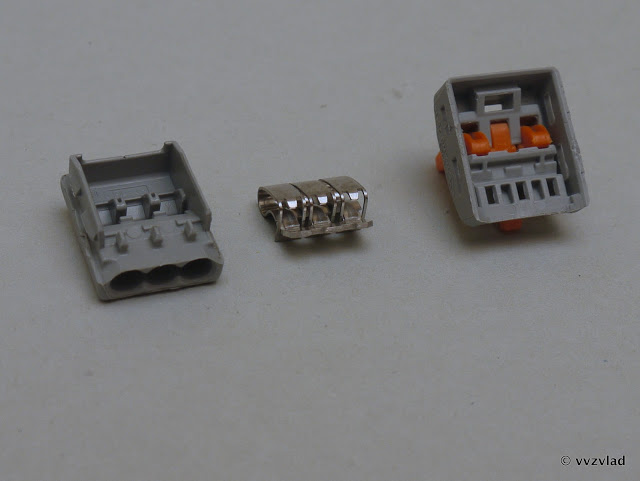

Terminals WAGO series 222 with levers. Saw only vagovskie, others do not produce.

For especially difficult cases, when there are several types of wires, of different thickness, aluminum, copper and so on.

Raise the lever:

We push the wires, lower the lever:

If necessary - you can raise the lever, pull out the wire, insert another. And so many, many times. A great thing for those circuits whose wiring can change a bunch of times.

Eat everything. Current - up to 32A. Inside - a plate that presses to a common tire is connected to the lever.

Sly design, in general.

Bob - tinned copper, as usual:

Cost: from 5 to 15 rubles.

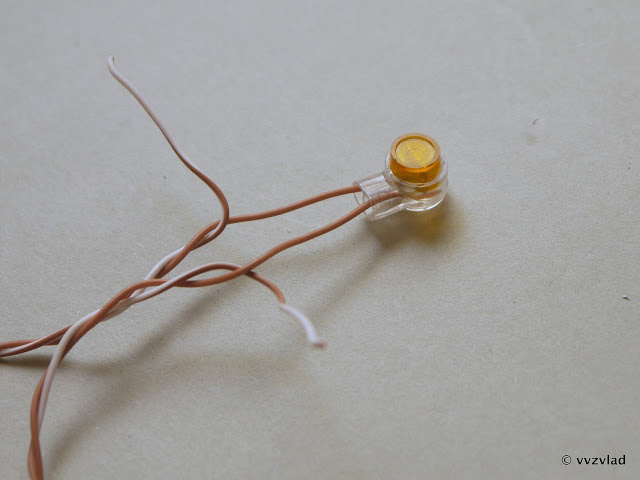

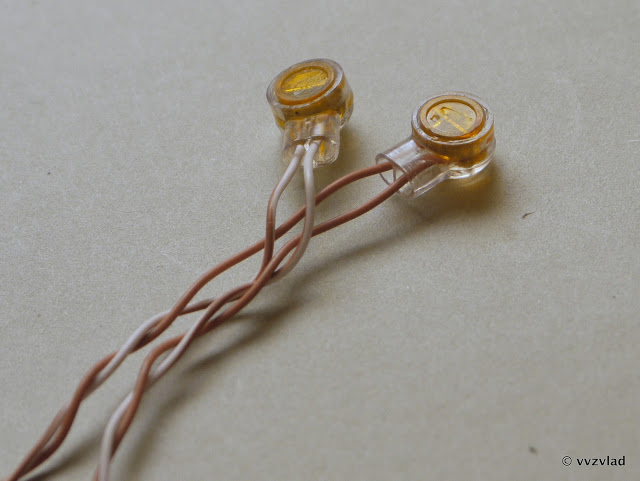

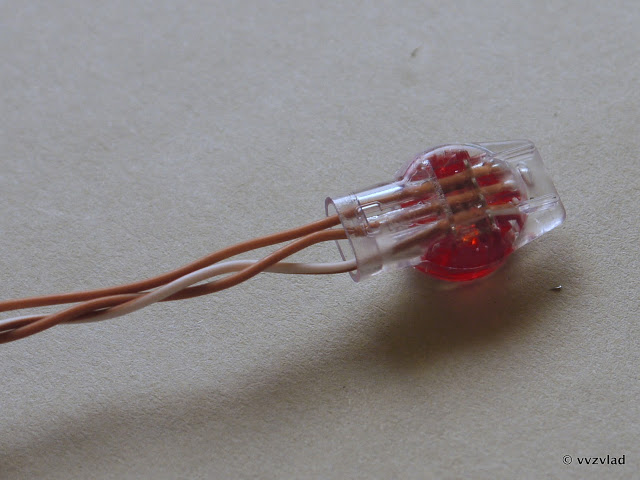

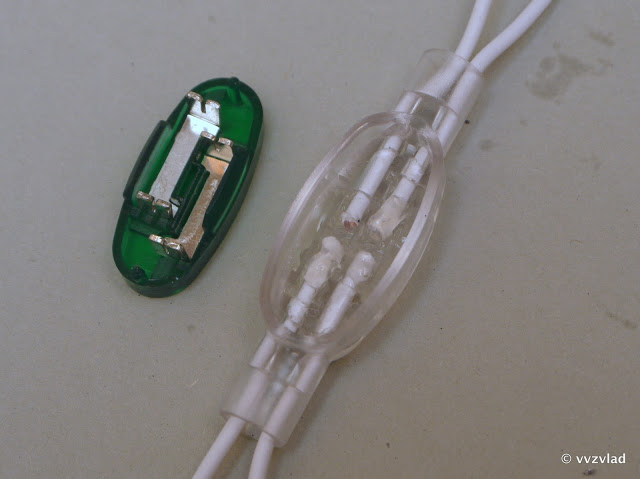

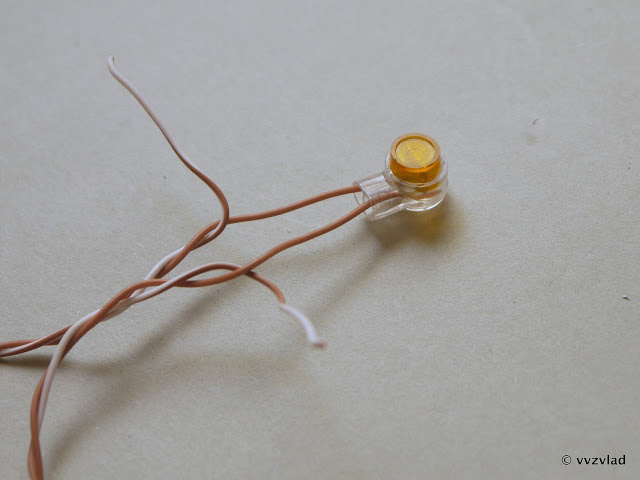

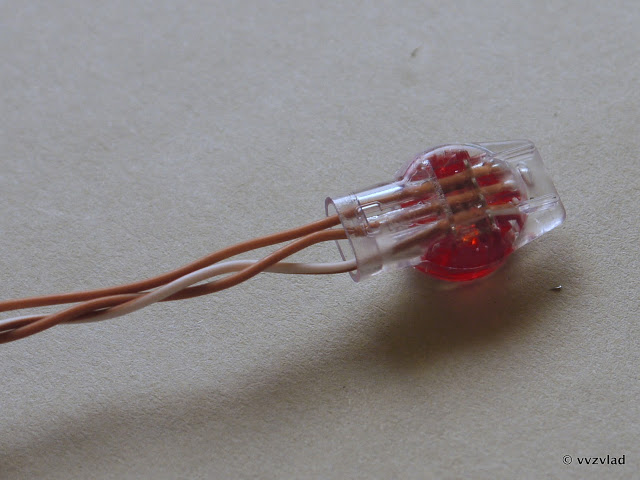

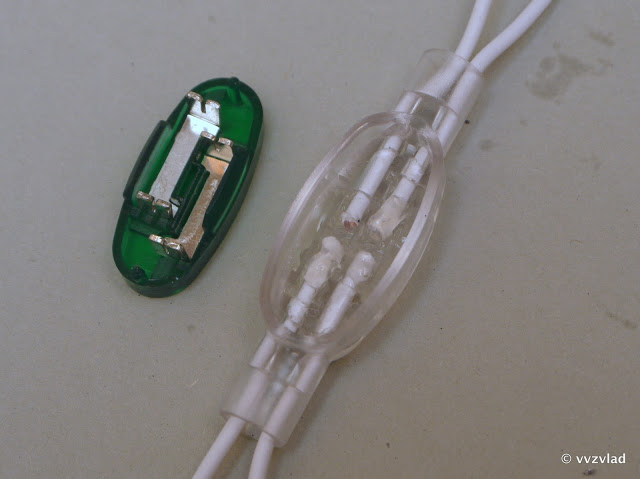

ScotchLok, ScotchLok, electrical connector with mortise contact.

This is for low voltage (network, telephones, LED lights, etc.).

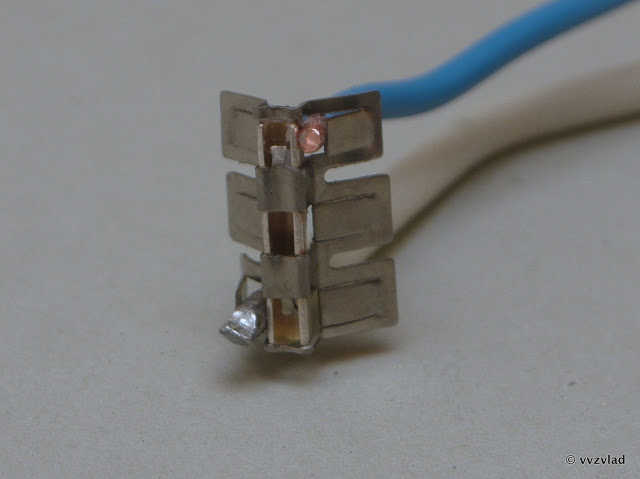

The point is simple - several wires are pushed into such a thing:

After which it snaps into the pliers or any oppressive tool. No, there is of course a special tool, but I do not see the point in it - it is a small pliers with flat jaws.

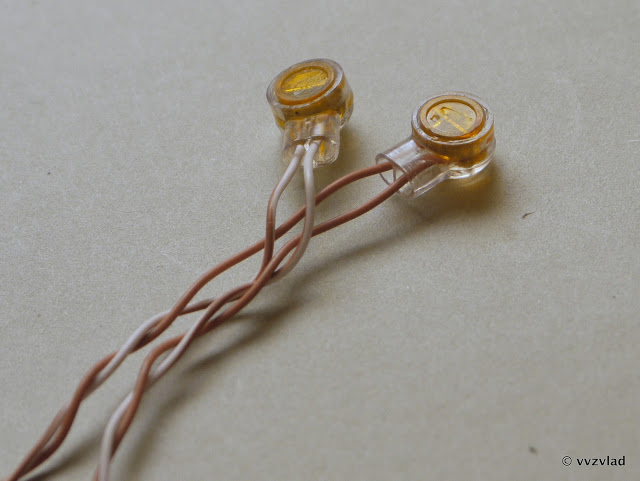

They are especially loved by the installers of the SCS and networks, for simplicity, cheapness, water resistance, and the lack of the need to remove the insulation.

Inside - a hydrophobic gel that protects against corrosion, moisture, oxidation, etc. And a plate with a cutting-clamping surface:

Or two plates:

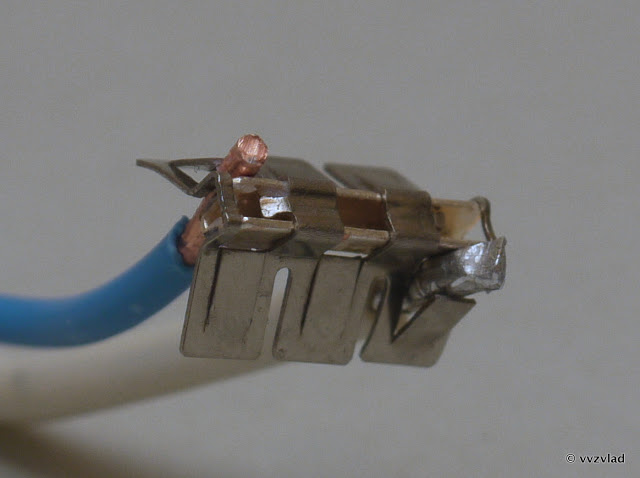

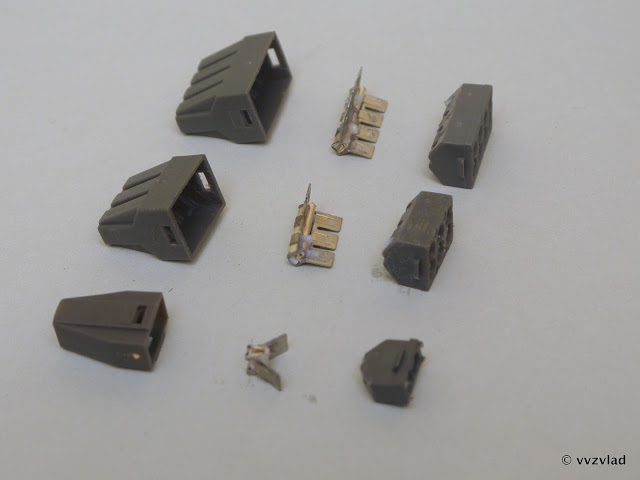

Here you can see what happens with the cable after termination:

Knives cut the insulation, and firmly pressed to the wire. There is also a version for two cables at once, and the plates are a bit thicker - quite suitable for lighting:

By itself, they are disposable and maintenance-free. It is necessary to replace - a piece of cable is bitten off with them, and a new one is put.

Cost: from 1 to 4 rubles apiece.

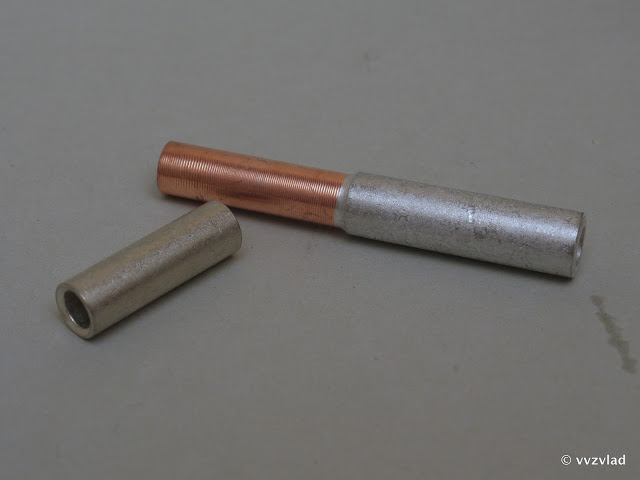

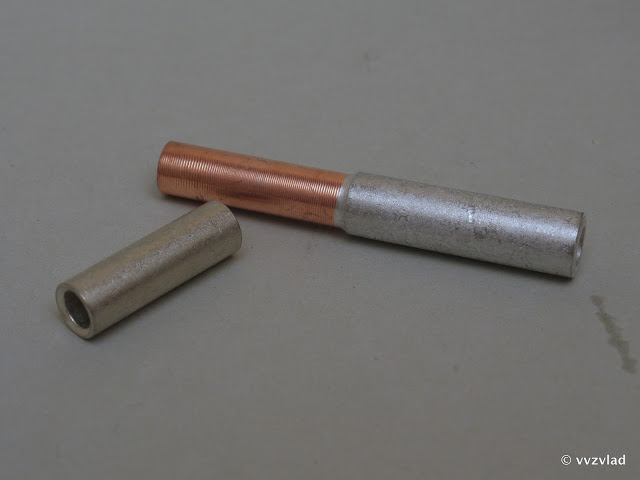

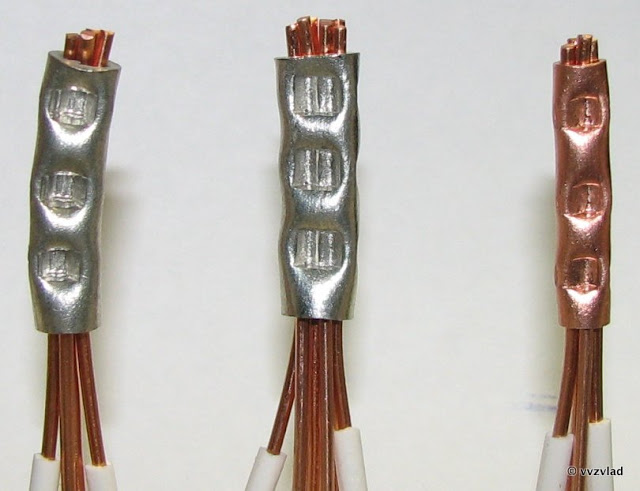

For high currents

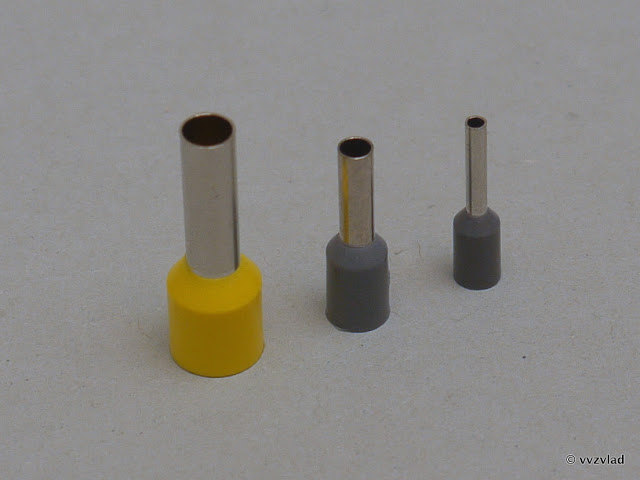

For such cases, there are liners:

Above - a sleeve connector of aluminum and copper cable, below - universal copper tinned:

Inside the wire is thrust (or several), the sleeve is crimped with a special tool. Unfortunately, some bad man put his ticks on me, so I will not show them. I found a picture in Google:

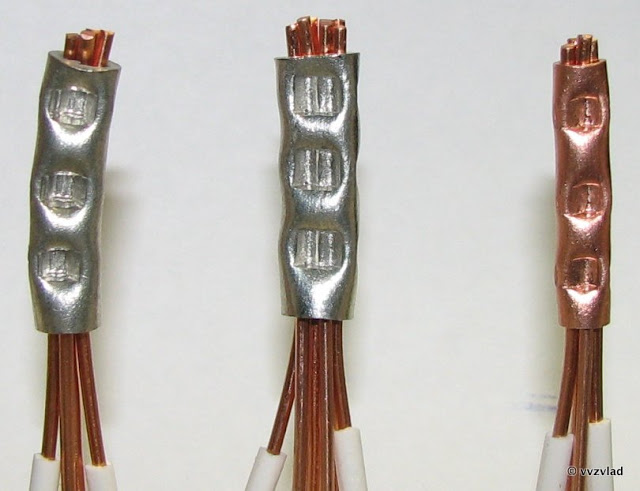

And here is the crimped sleeve:

A huge plus is that with the right choice of size and proper crimping, the resistance does not decrease compared to a conventional wire. And the unattended, which is sometimes important. This means that you can wall it (after normal insulation, of course) into the wall, bury it in the ground (taking care of waterproofing), and so on.

Flat-ended and bore sleeves are mainly used for grounding, when the wire must be connected to the housing:

Sleeves with screw clamp - when you need to hold the wire without a tool.

Currents are similar to currents for that section of copper wire, which coincides with the inner diameter of the sleeve. \

Cost: from 10 rubles per sleeve, from 1000 per snap.

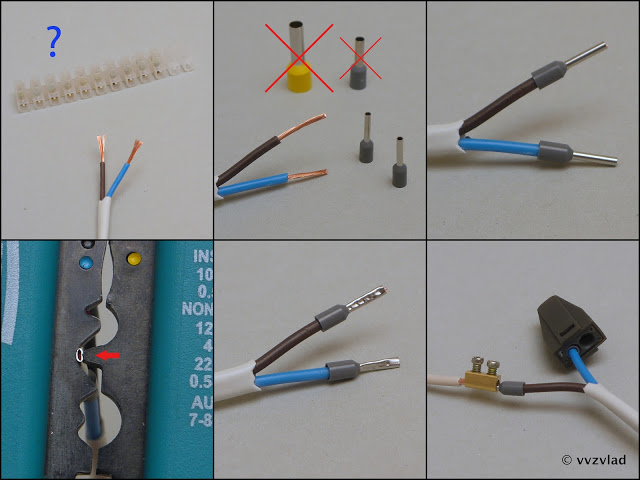

And there is also a situation when it is necessary to connect a single-core wire with a multicore one:

No, in general, you can cheat and clamp already as a monozhilu. But there is an easier option:

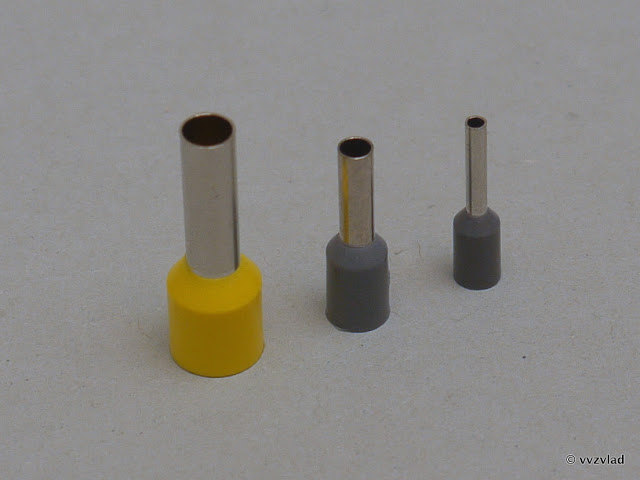

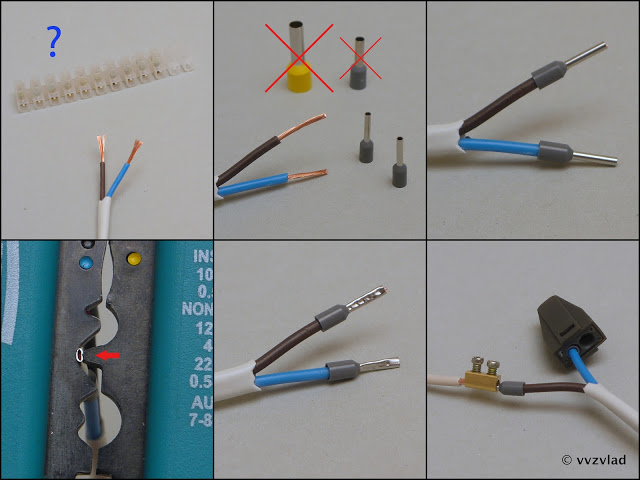

They are called NSHVI - Tip Pin Bushing Isolated. The meaning is simple:

We select its diameter under the cross-section of the wire, lightly twist it so that it does not push, put on the tip and press it all the way along (well, at least 3-4 times). Everything, now this wire can be clamped in any connections, without being afraid that the conductors will break off, the contact or something else will be broken. It is important to choose the tip diameter correctly depending on the wire, otherwise the contact will be worse and the wire may slip out.

You can even clamp them with a hammer with a screwdriver or pliers, but it’s better with a special tool, it’s not very expensive - from 500 rubles to 2000. It’s better, of course, not to take Chinese, but to take 30-40% more than the minimum price.

I use this:

Wire Stripper Combination:

And swage:

View all photos from the article (and many not included) in the original resolution can be in the Picasa-album .

And to subscribe to me, so as not to miss new articles, you can in my profile (button "subscribe")

About normal wiring

When I see this, I feel uncomfortable:

And when I see this, I want to kill the author:

The fact is that you can not twist copper and aluminum wires in any way.

There are several reasons for this. The main problem is the oxidation of aluminum wire in contact with copper - a galvanic pair is formed, which slowly but surely destroys the connection. And the faster, the greater the current through this twist goes.

Of course, in a couple of hours, such a connection will not fall apart, even if a heater or a kettle is turned on through it. But over time, the resistance will slowly increase, because of which the twist will warm up stronger and stronger. And if the load is not constant, but episodic, then constant heating-cooling cycles will worsen the conductivity even more. When heated, different materials expand in different ways, and switching on and off of the load through such a twist will be equivalent to constant twitching it back and forth. You understand that it will not lead to anything good.

Well, if just heating, it can usually be traced by the characteristic smell of burning insulation. But the arcing of the compound, especially near the wallpaper or something flammable, can easily turn into a fire.

What solutions exist to solve this problem?

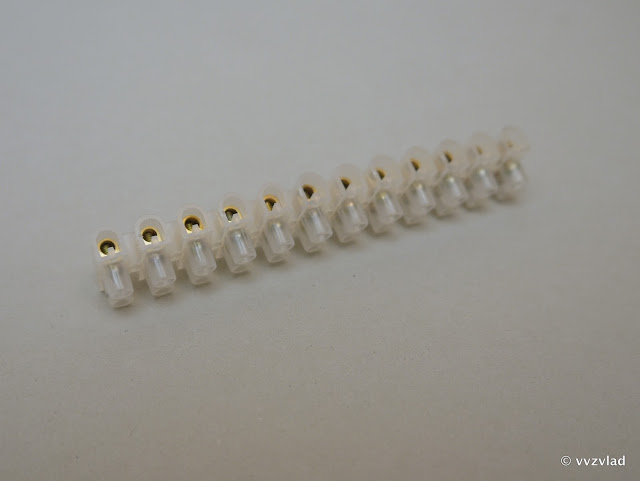

Polyethylene terminal blocks

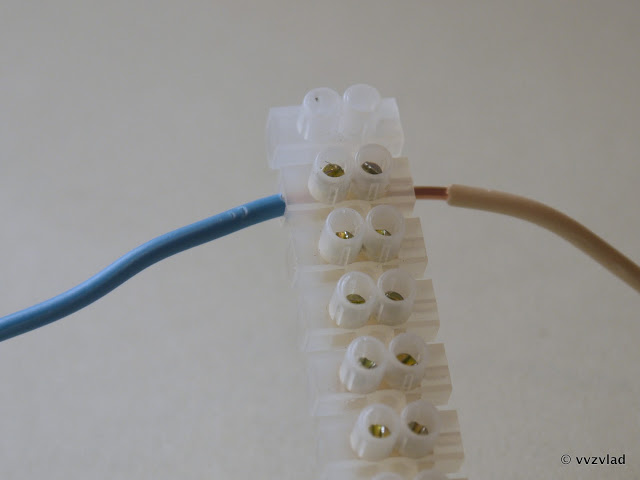

Here's a thing:

Sold in any hardware store, worth a penny.

Inside here is a brass sleeve with two screws:

We push wires into it, we clamp with screws:

<

I specifically pulled it out for clarity. Together with isolation, it will look like this:

Each segment can be cut off. It would seem ideal. But there is a nuance (s)

Although these nuances and shortcomings - the car and a small truck, do not be fooled by the simplicity.

- Do not clamp aluminum. The aluminum core has fluidity under constant pressure, and after a while the contact can easily disappear or deteriorate. What is fraught with - you know, heat and fire. Strictly speaking, ALL aluminum screw connections need to be tightened once a year. Otherwise, it looks like this:

The photo shows that the extreme clamp lost contact, began to spark and heat up - as a result, it melted its sheath and a bit of wire insulation. Has been replaced by the same hehe. - Do not clamp stranded wires. There is a complete set of what the stranded wire does not like - and the rotational movement, and the uneven surface of the screw, and the dotted uneven pressure. Maybe everything is fine, special if the current is small, and maybe not lucky and half of the wires will remain from the wire. Next you know.

- It is necessary to choose the size under the cross section of the wire. The wire does not fit into too small a diameter, and it is inconvenient to clamp too large, worse contact and more freedom - the risk that the wire will fall out or break off.

- If you hold a little bit harder, hard, but fragile brass will crack easily. What is fraught with bad contact, and ... Well, you understand.

- Do not pay attention to the plates with currents when buying. They are lying. Divide the current by two, and better by 3.

It is generally advisable not to use such terminal blocks. If you use, then only with single-conductor wires and for connecting something small - a light bulb, a fan (not industrial). And no aluminum!

It is also advisable not to buy noname China, but the terminals of normal manufacturers: Tridonic, ABB, Legrand, Believes

Cost: from 10 to 50 rubles.

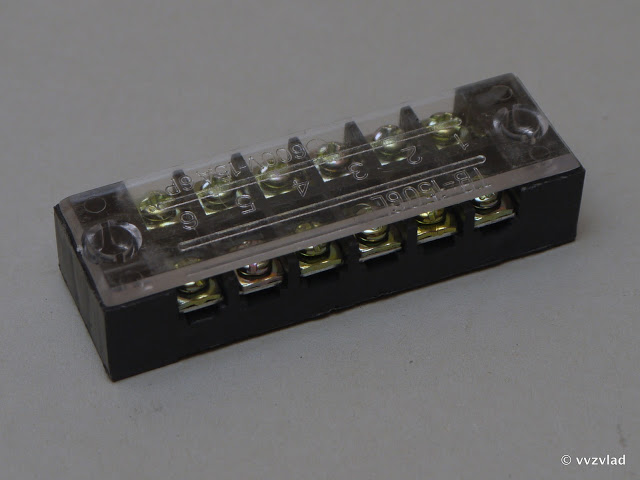

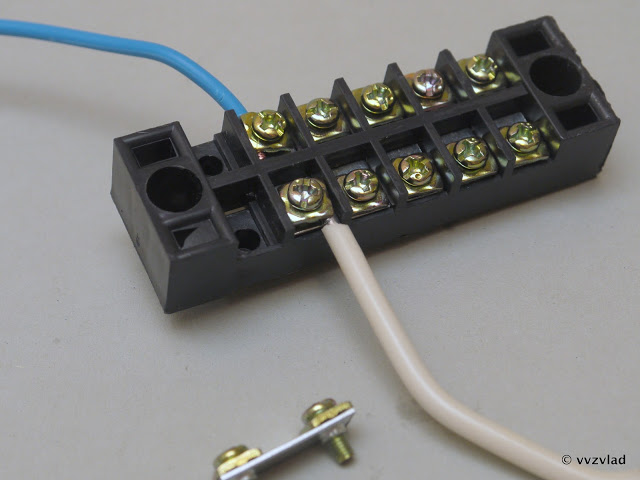

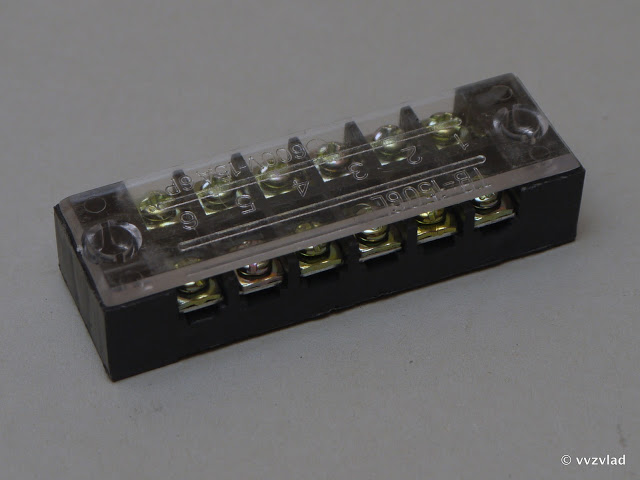

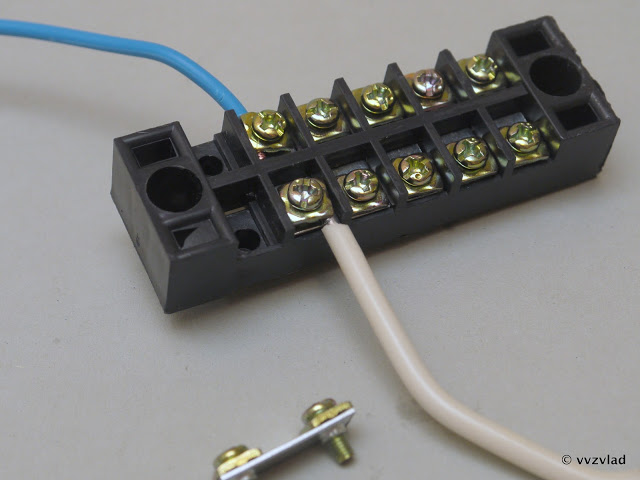

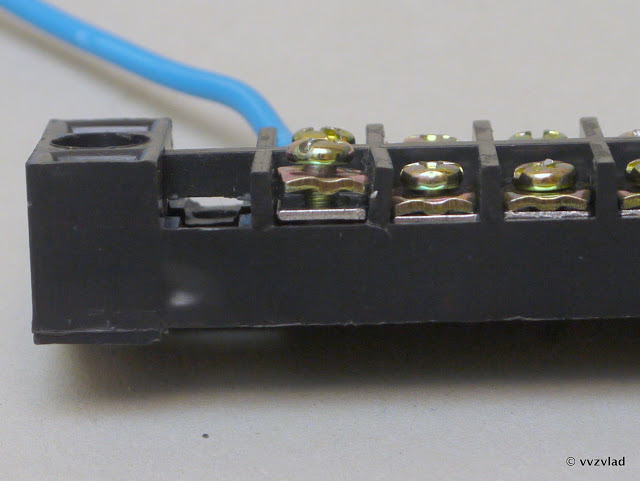

TB Series Terminal Blocks

Solid black plastic pads. Already better.

Have a removable cover:

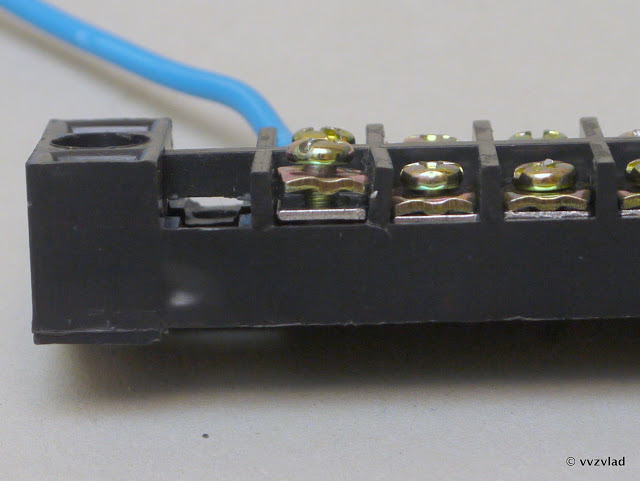

And here is the internal structure:

Turn off, thrust the wire, clamp.

Pros - clamps, not a screw, but a metal plate. We press to the bottom steel plate. In addition, the upper part is not flat, but with a characteristic surface that increases the surface of the clamp:

.

.Due to this, you can clamp the stranded and aluminum wires. Aluminum, however, it is desirable to at least sometimes check for loosening clamping. I saw the pads on currents 25A and 40A.

The inconvenience is not cut and does not divide, either buy a bunch of small ones (I have not seen less than 6 pieces), or even put one big one on two wires.

Cost: from 30 to 80 rubles.

')

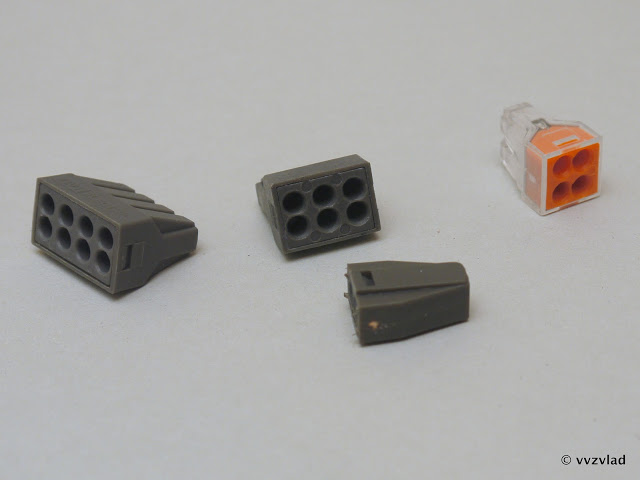

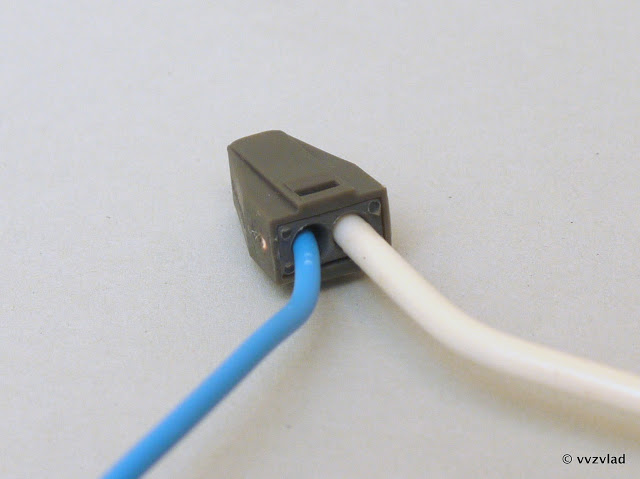

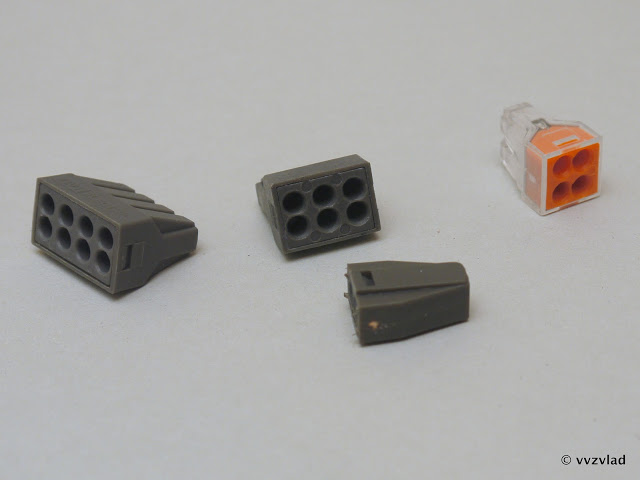

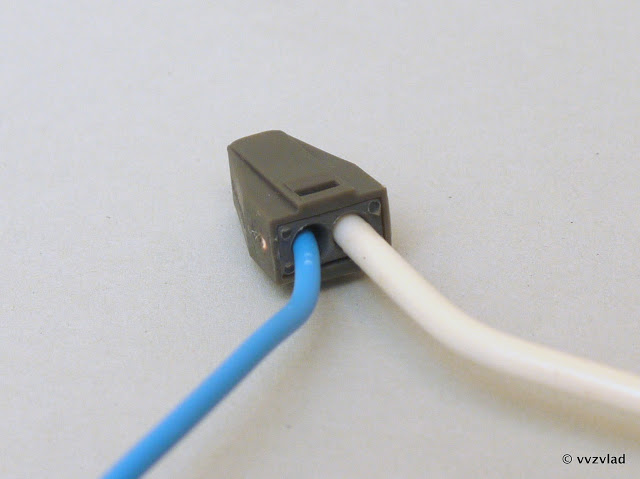

Self-tightening terminals (WAGO or REXANT series 773 and their copies)

Or they are also called express terminals. Like these ones:

Very handy stuff. Cleared the wire, put it in to the end, ready:

<

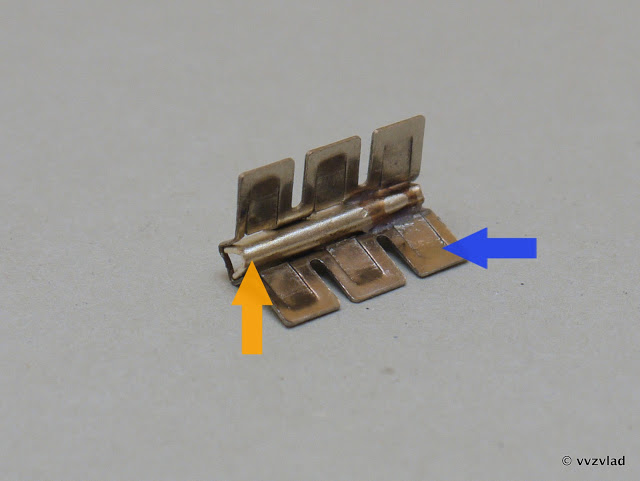

Inside there is a pressure plate (blue arrow) and a small bob (orange) made of tinned copper:

When wires are stuffed into it, what happens is:

The plate presses the wire to the tavern, keeping the pressure all the time. And the design of the pressing part on gives the wire to fall. You can hardly get him out. In general, they are disposable, but if you really want, then you can gently rotate the wire around its axis.

Since the copper contact is tinned, you can insert aluminum wire into such a terminal without fear of problems. At the same time, constant pressure will not allow the aluminum wire to fall out.

The white paste (on the next photo you can see the white mass on the contact) is quartz sand with technical petroleum jelly, especially for aluminum wires. Quartz sand is an abrasive that clears the oxide film from the surface of aluminum, and petroleum jelly does not allow it to form again.

The same terminals, but transparent:

They are no different than the dye. Well, in transparent terminals it is more convenient to see the wire - they are pushed to the end or not.

Plastic - non-flammable, melts with increasing temperature, without emitting harmful substances into the air.

Designed for 25 A, and this is about 4 KW. Attention! Currents are indicated for original WAGO terminals only.

Terminals Rexant (manufacturer - VTS groups), use another spring steel, which relaxes when heated. Accordingly, the maximum current is limited, except in lighting is not recommended.

Here is a test in which they kept 50A and did not even melt. Well, it is in ideal conditions - in the air, the cooling was good. And the original terminals, yes.

Cost: from 2 to 6 rubles, depending on the number of contacts

Terminals WAGO series 222 with levers. Saw only vagovskie, others do not produce.

For especially difficult cases, when there are several types of wires, of different thickness, aluminum, copper and so on.

Raise the lever:

We push the wires, lower the lever:

If necessary - you can raise the lever, pull out the wire, insert another. And so many, many times. A great thing for those circuits whose wiring can change a bunch of times.

Eat everything. Current - up to 32A. Inside - a plate that presses to a common tire is connected to the lever.

Sly design, in general.

Bob - tinned copper, as usual:

Cost: from 5 to 15 rubles.

ScotchLok, ScotchLok, electrical connector with mortise contact.

This is for low voltage (network, telephones, LED lights, etc.).

The point is simple - several wires are pushed into such a thing:

After which it snaps into the pliers or any oppressive tool. No, there is of course a special tool, but I do not see the point in it - it is a small pliers with flat jaws.

They are especially loved by the installers of the SCS and networks, for simplicity, cheapness, water resistance, and the lack of the need to remove the insulation.

Inside - a hydrophobic gel that protects against corrosion, moisture, oxidation, etc. And a plate with a cutting-clamping surface:

Or two plates:

Here you can see what happens with the cable after termination:

Knives cut the insulation, and firmly pressed to the wire. There is also a version for two cables at once, and the plates are a bit thicker - quite suitable for lighting:

By itself, they are disposable and maintenance-free. It is necessary to replace - a piece of cable is bitten off with them, and a new one is put.

Cost: from 1 to 4 rubles apiece.

For high currents

For such cases, there are liners:

Above - a sleeve connector of aluminum and copper cable, below - universal copper tinned:

Inside the wire is thrust (or several), the sleeve is crimped with a special tool. Unfortunately, some bad man put his ticks on me, so I will not show them. I found a picture in Google:

And here is the crimped sleeve:

A huge plus is that with the right choice of size and proper crimping, the resistance does not decrease compared to a conventional wire. And the unattended, which is sometimes important. This means that you can wall it (after normal insulation, of course) into the wall, bury it in the ground (taking care of waterproofing), and so on.

Flat-ended and bore sleeves are mainly used for grounding, when the wire must be connected to the housing:

Sleeves with screw clamp - when you need to hold the wire without a tool.

Currents are similar to currents for that section of copper wire, which coincides with the inner diameter of the sleeve. \

Cost: from 10 rubles per sleeve, from 1000 per snap.

About stranded wires

And there is also a situation when it is necessary to connect a single-core wire with a multicore one:

No, in general, you can cheat and clamp already as a monozhilu. But there is an easier option:

They are called NSHVI - Tip Pin Bushing Isolated. The meaning is simple:

We select its diameter under the cross-section of the wire, lightly twist it so that it does not push, put on the tip and press it all the way along (well, at least 3-4 times). Everything, now this wire can be clamped in any connections, without being afraid that the conductors will break off, the contact or something else will be broken. It is important to choose the tip diameter correctly depending on the wire, otherwise the contact will be worse and the wire may slip out.

You can even clamp them with a hammer with a screwdriver or pliers, but it’s better with a special tool, it’s not very expensive - from 500 rubles to 2000. It’s better, of course, not to take Chinese, but to take 30-40% more than the minimum price.

I use this:

Wire Stripper Combination:

And swage:

View all photos from the article (and many not included) in the original resolution can be in the Picasa-album .

And to subscribe to me, so as not to miss new articles, you can in my profile (button "subscribe")

Source: https://habr.com/ru/post/157947/

All Articles