Two crazy ways to finish the chips

- An atom consists of a nucleus and electrons that are around it.

- What is between the nucleus and the electrons?

“Well ... how what? Air!

Like an atom, the body of the chip consists mainly of plastic

Like an atom, the body of the chip consists mainly of plastic In theory, yes. But in practice?

1. Sawing across

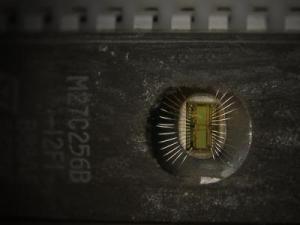

Gregory Davill decided to build the simplest RFID emulator on the MSP430G2211 microcontroller, but he was haunted by the large case size (DIP-14). Of course, it would be possible to take a smaller case, or, at worst, choose another model of the controller, but this is not interesting! Therefore, Greg went the other way, and, taking the Dremel, sawed off on a piece of body from two sides:

')

As a result, the MSP430 family has been replenished with a new - six-legged - model.

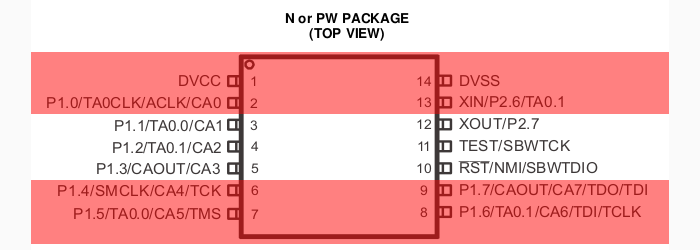

The crystal was not touched, so the MK remained fully operational, not counting the loss of eight “extra” conclusions. But hey, the power pins are now cut off too! How will it work? In the usual scheme - it will not, but here is one interesting hack. This RFID tag consists of only two parts: the controller and the coil.

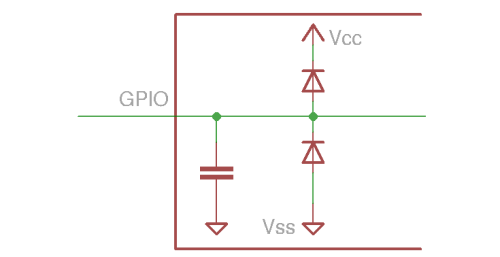

The controller receives power from the EMF variable induced in the coil by the reader field. The voltage is rectified by built-in protective diodes, a pair of which “hangs” on each pin of the controller, and is fed to the internal power supply buses.

The clock signal is removed from the same coil. Thus, all conclusions, except two, are not needed, and they can be cut off without fear (of course, you need to fill in the firmware in advance). This trick will also work with PIC and AVR controllers.

A source

2. Sawing along

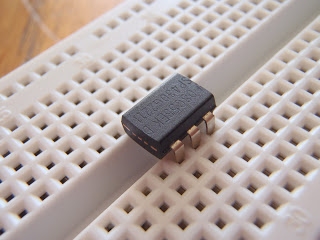

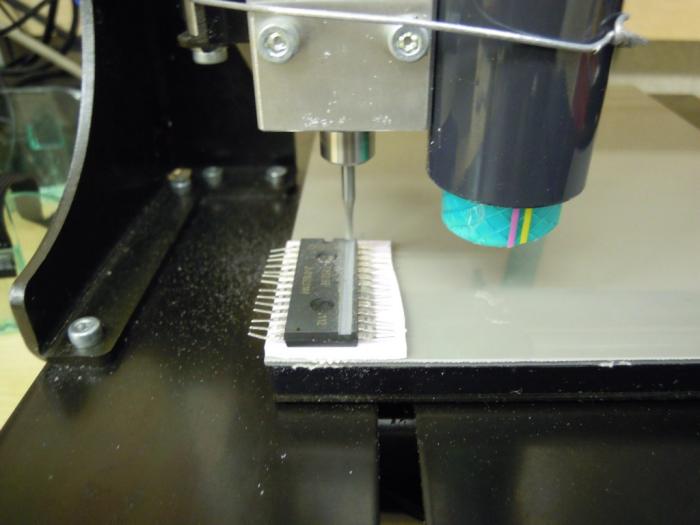

The LPC1114 controller is currently the only ARM in the “friendly” DIP package. It is easy to solder it for beginners, it can be plugged into the breadboard without adapters. Joy overshadows only the large width of the case - 600 mil (15.24 mm). The Japanese under the name TheAxid9999 was able to finish this controller to half the width (300 mil).Just straight hands and a grinder can not be done here, so the controller was fixed on the table of the milling machine ...

... and for several passes cut 150 mil from each of the sides. Together with the legs.

Now, to connect to the crystal, you need to get to the metal paths that go into the body of the case. On the same machine, taking down a fraction of a millimeter per pass, two grooves were carefully milled, revealing a layer with tracks, but without damaging the latter.

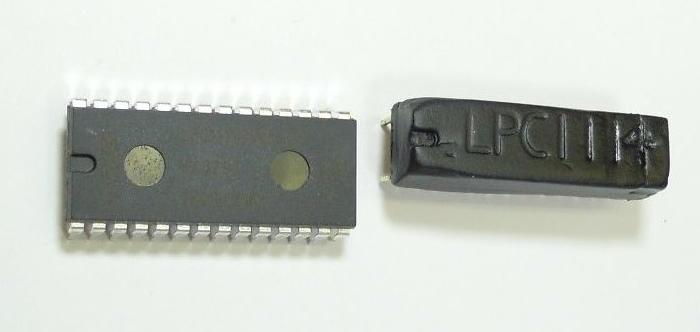

The hardest thing behind. Now it is possible to solder new conclusions made from two connectors-comb to the controller.

So that the entire structure could be removed from the board without being afraid of breaking, it was filled with epoxy resin. After solidification of the polymer, it was again milled to give a smooth shape.

Here is the result in comparison with the untouched case. The width has been halved, although at the cost of increasing the thickness.

Video instruction:

Source (in Japanese)

Conclusion

In addition to "along" and "across", there was still one way to cut chips: horizontally. Unlike the first two methods, horizontal cutting is not useless fun, but quite a serious tool. It is used to access the crystal for:- Works with the microcircuit, in which the crystal connections with the leads are broken;

- Extracting protected data, for example, locked firmware;

- Reverse engineering.

Well, the methods described in this article, of course, have no practical application and are considered solely as “Just for fun”. All modern microcircuits are produced in miniature cases, and if dimensions are important, it is enough to choose a suitable version, and not to engage in artistic carving on DIP-cases.

Source: https://habr.com/ru/post/157293/

All Articles