Upgrade discrete graphics MacBook Pro 15 "late 2011: solder video memory from 512MB to 1GB

I continue a series of posts dedicated to upgrading computers Apple. This time it will be about the MacBook Pro 15 "(A1286) 2011 release. A very decent device, in my opinion: a quad-core Intel Core i7 processor, Ati 6 series graphics, support for 16GB of RAM 1333MHz. His performance and today, is enough for most tasks.

Apple has released four complete sets of this model, which is different processor and graphics. Detailed specifications, see the table. The experiment was conducted on a complete set of MD 318 (i7 2.2GHz, Ati 6750M (512MB)). The standard video memory (vram) with a volume of 512MB was soldered to more capacious chips and received 1GB vram.

')

Table. Specifications A1286 2011

| Model | MacBook Pro 15 "A1286 | |||

| Year | the beginning of 2011 | end of 2011 | ||

| Equipment | MC721 | MC723 | MD318 | MD322 |

| Identifier | MacBookPro 8.2 | |||

| Graphics (vram) | 1. Intel HD 3000 | |||

| 2. Ati Radeon HD 6 series | ||||

| Ati 6490M (256MB) | Ati 6750M (1GB) | Ati 6750M (512MB) | Ati 6770M (1GB) | |

| Chipset | Intel BD82HM65 | |||

| Video chip | 216-0809000 | 216-0810005 | 216-0810005 | 216-0810084 |

| EFI version | MBP81.0047.B27 | |||

| SMC version | 1.69f3 | 1.69f4 | ||

| Pay | 820-2915-A | 820-2915-B | ||

| CPU (cache) | Quad-core Intel Core i7 | |||

| i7 2.0GHz (6MB) | i7 2.2GHz (6MB) | i7 2.2GHz (6MB) | i7 2.4GHz (6MB) | |

| Memory | 1333MHz DDR3 (PC3-10600), max 16GB | |||

I’ll tell you more about the key points, I’m not going to describe the BGA soldering process, those who wish can “google” on their own how this is done.

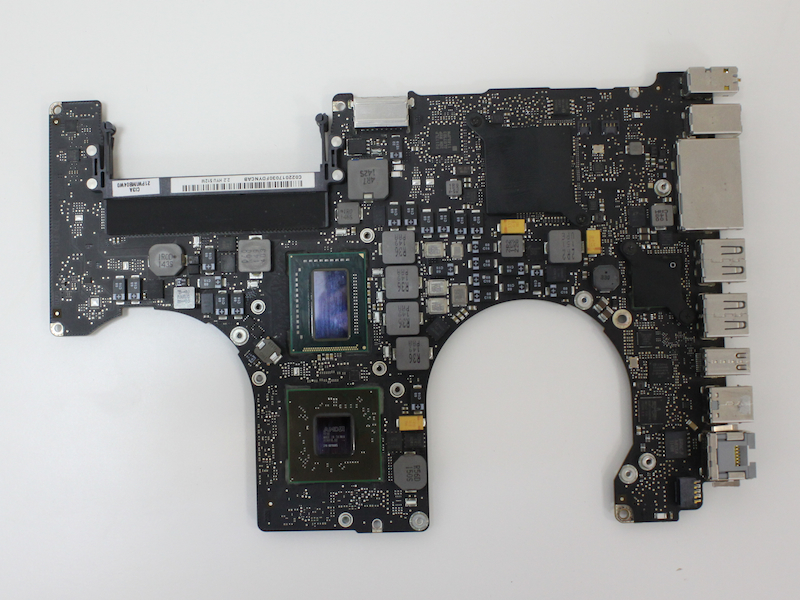

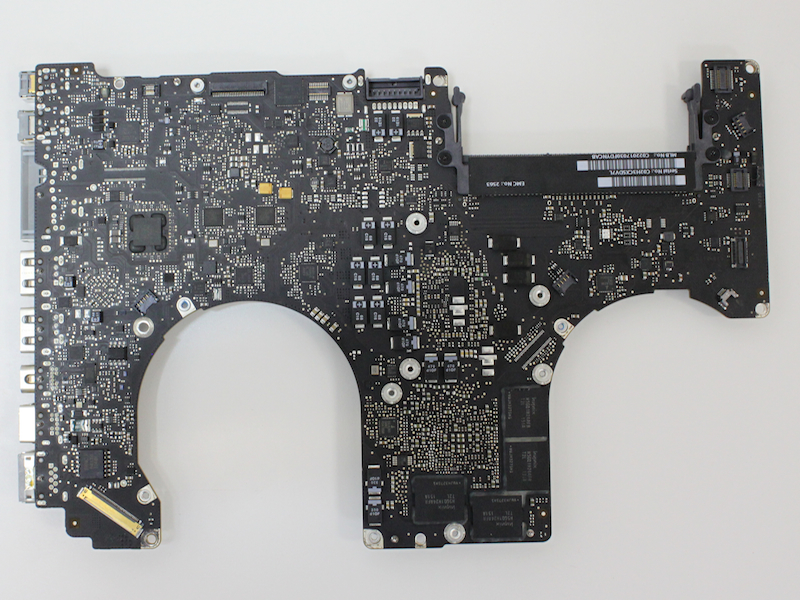

We sort and get the board.

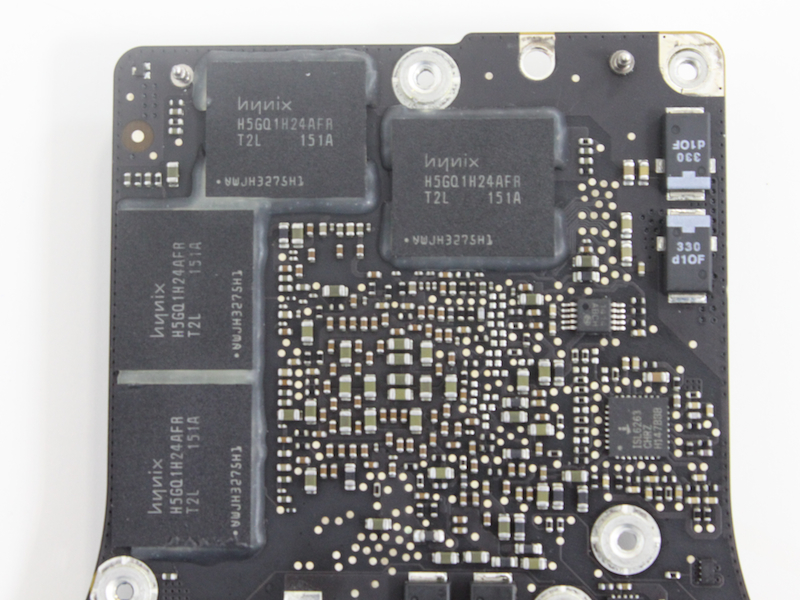

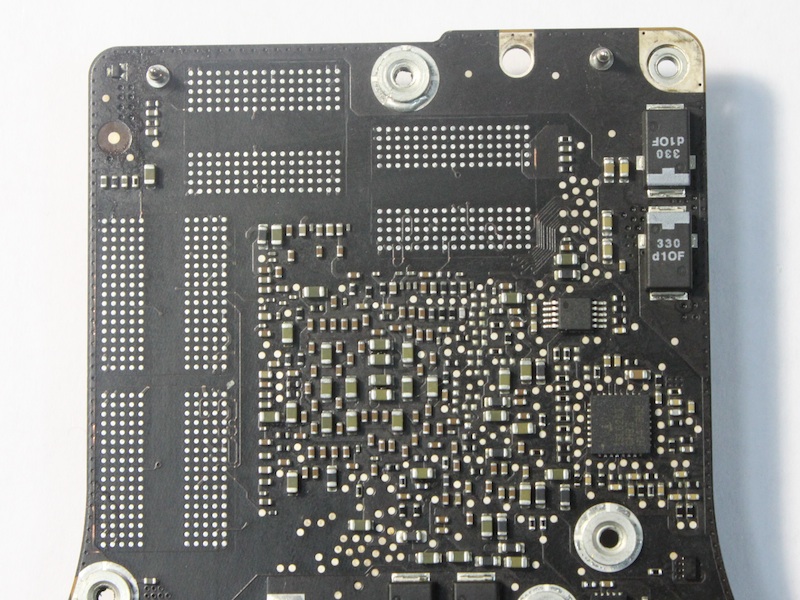

The board has 4 video memory chips Hynix H5GQ1H24AFR T2L. This is a GDDR5 SGRAM with a 1Gbit volume (128MB single chip) and a transfer rate of 5 Gbit / s.

We unsolder the chips.

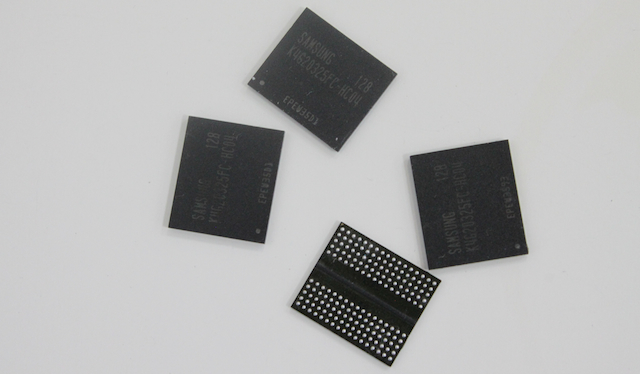

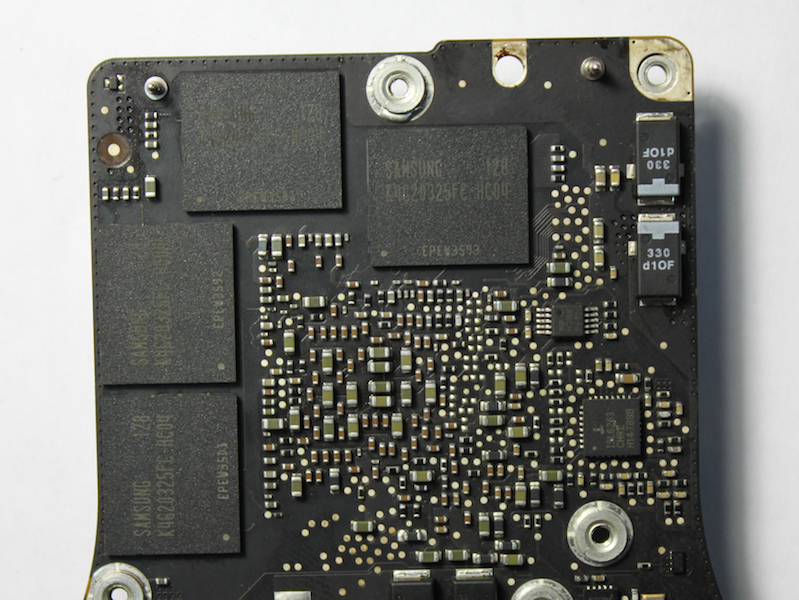

Instead, we hang Samsung K4G20325FC-HC04. This is also GDDR5 SGRAM with the same transfer rate of 5 Gbit / s, but already with a volume of 2 Gbit (256 MB one chip). It is this memory that is installed in custom configurations, where the graphics are from 1GB of video memory.

New chips.

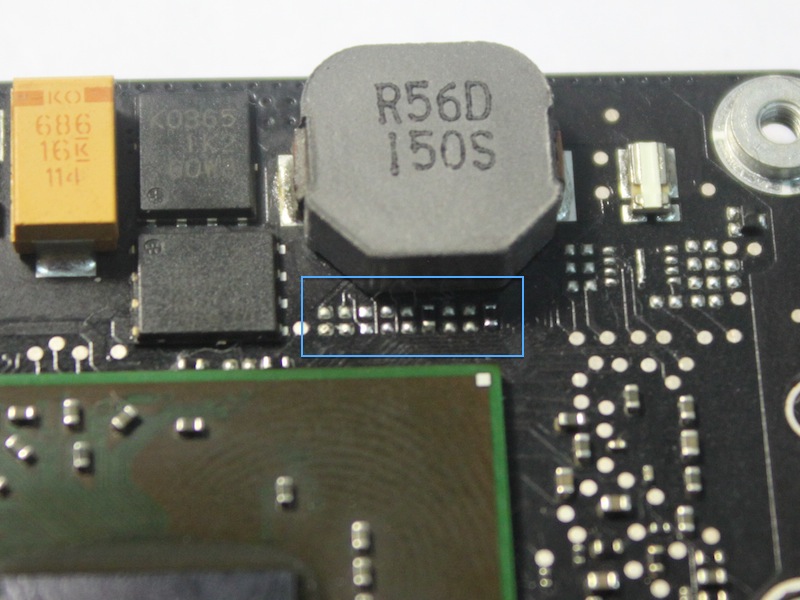

Finally, we solder strap resistors. Install them according to the resulting configuration.

Strap resistors.

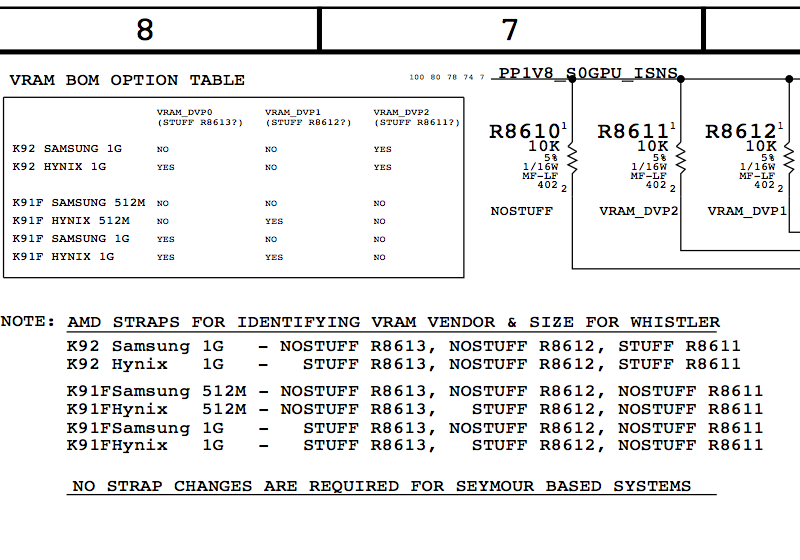

The values of the “straps” are indicated in the circuit diagram to the motherboard. A different configuration of graphics (video chip model, memory manufacturer, memory size) corresponds to a certain combination of stresses.

Part of the circuit with straps

Now everything is ready. We collect poppy and enjoy the result.

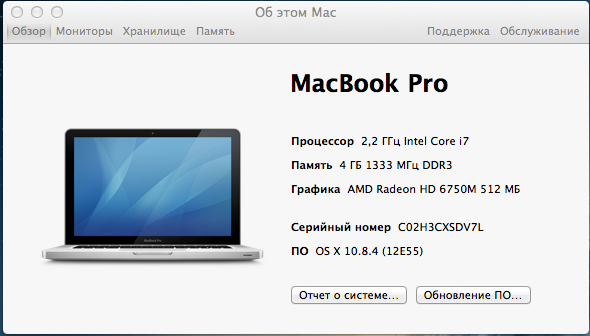

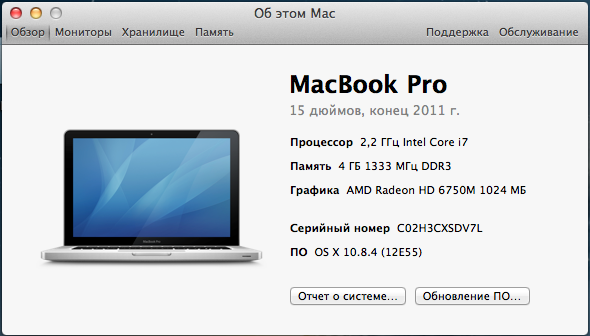

Screenshot before and after.

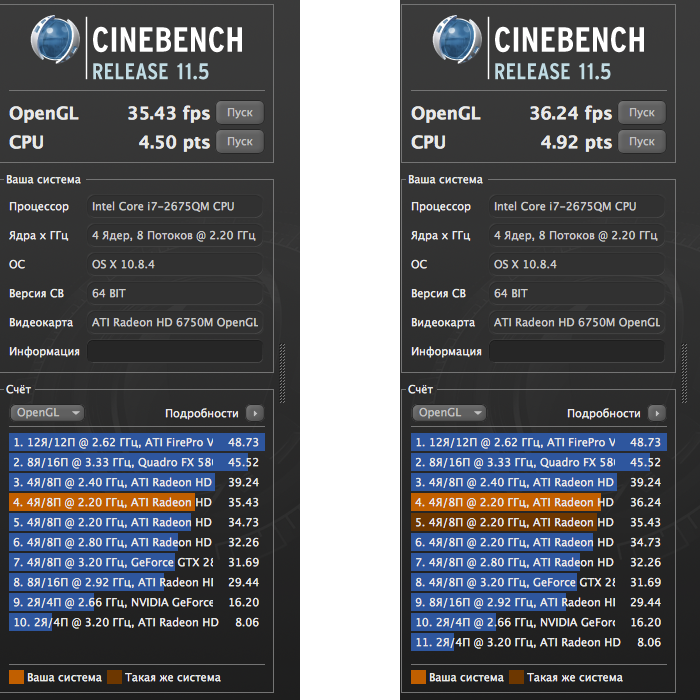

Cinebench test result.

It turned out that from the stock configuration MD318, we made a custom MC723. It would be possible to re-solder the video chip on the Ati 6770, but unfortunately it wasn’t such available. Moreover, the video chip is still changing. This poppy was brought in for repair with a video chip malfunction. We suggested the owner to conduct an experiment and solder the video memory.

Source: https://habr.com/ru/post/156313/

All Articles