Minor repair and calibration of APC SmartUPS 700

This article has been visited in some aspects of the operation and non-independent repair of APC SmartUPS 700 and similar UPS systems.

All this information is provided "as is" for review and neither I nor APC is responsible for its use in practice. At your peril. There are 220 volts, I warned you.

Prehistory

I had this representative of uninterruptible power supplies for many years in good health until something heavy was dropped on the lid in the center, after which the patient completely “fell off the brain” and he did not become unconscious.

(it should be noted that there was already no protective film on top of the board, it was lost in the service centers)

An autopsy revealed several burnings in the region of contact between the grounded cover and the board and traces of old (not mine) repairs. Since there was an opportunity, the UPS was put into service, where he was brought to life, and he was still working for half a year, after which he began to behave inadequately. It was decided to connect it to the computer and check the thresholds, battery charge, etc., well, then he is “smart”, which he can show a lot of things.

Connect.

And here the problems started, none of the laces for connecting it to the computer worked, as well as none of the existing cord. All the programs said that the UPS is not connected, and the only thing that was seen in the terminal is the "?" Sign that appears when turned on, which indicated that the mains voltage had suddenly disappeared. After a long study of the manuals, the following data was found:

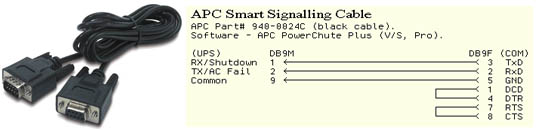

For communication over the Smart protocol, you need a 940-0024C cord, here it is and its wiring.

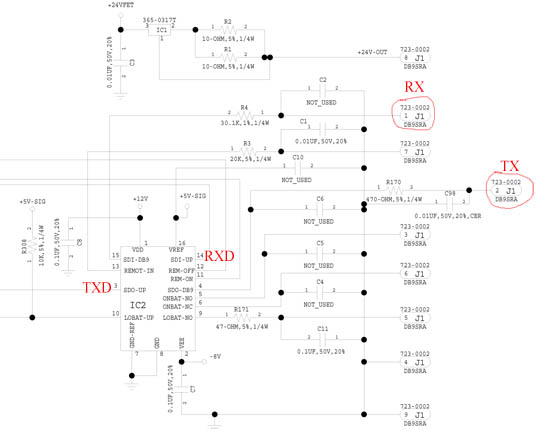

But, As already mentioned, the connection under this scheme did not bring success. After further digging into the global garbage dump, the Smart UPS 700 circuit was excavated, or rather the 640-0730P board, although I had version 640-0730N, the differences were not fundamental. It was found out that the signals on the DB9F connector on the rear panel of the UPS get through the specialized IC2 chip (according to the scheme), obviously, among other things, performing the isolation and matching of TTL UART with RS232 levels.

The RX (1 DB9) and TX (2 DB9) connection lines of interest connect, respectively, to pins 15 (SDI) and 4 (SDO) of this chip. Testing resistors and capacitors in these lines yielded nothing, from which it was suggested that the SDI IC2 input would burn out. Since there was nothing to replace the chip, it was decided to try to connect to the UPS bypassing it. In this model, the UPS uses a microcontroller P83C654. A quick reading of the datasheet on it showed that communication with the outside world takes place through the standard Full Duplex UART, with TTL levels of 5V, and they come to the findings of SDO-UP (3 IC2) (TXD) and SDI-UP (14 IC2) (RXD) late chip IC2.

')

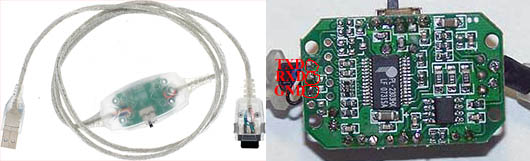

Next, the case of technology. A phone cord was purchased at the nearest cellular store, and in fact a USB-UART adapter on the PL2303 controller, a telephone jack was removed, only the RXD, TXD, GND lines were left.

Connect the cord with pins 3 (TXD), 14 (RXD), 8 (GND), connect at 2400 baud, 8bit data, 1 stop bit, no parity, and hurray! Everything is working.

According to the SMART protocol, of course, the remaining IC2 lines are not used.

Calibration.

Now, about why it all began. On occasion, I had 2 new 12V 7.2A / H batteries, after installing them, turning them on and checking under load at 2x100W light bulbs, the results were not encouraging - the UPS worked for a couple of minutes and disconnected with fully charged batteries ... Well, it is clear that something it's not like that Calibration with the “D” command in Smart mode did not work. Again we smoke mana.

The microcontroller stores all dynamic characteristics of a battery in register 0 of non-volatile memory, and as the battery ages, the decreasing value of the coefficient for calculating the capacity is entered into this register.

So, UPS itself cannot increase the value of this register when performing calibration! It is necessary to write there the default value - 0x96 (in hexadecimal) (for Smart UPS 700) manually, through the terminal, before calibration, and then, running the calibration with a load of 30-40%, have patience and wait ...

Ps. A couple of links that helped in solving the issue. SmartUPS protocol, register description, schema, all that does not fit here.

masterjoy.narod.ru/UPS/ups.html

www.saprjkin.narod.ru/UPS_SMART.htm

Source: https://habr.com/ru/post/151262/

All Articles