Contrast and durable marker board

As part of the gradual transition of the development process from natural to sane, i.e. to Agile, the question of drawing / changing graphs, charts, tasks and other things began to rise more and more acutely. Initially, we thought to buy a marker or chalk board in the nearest office store and use it, but then the idea to do it with our own hands appeared and gained power, and this article is about.

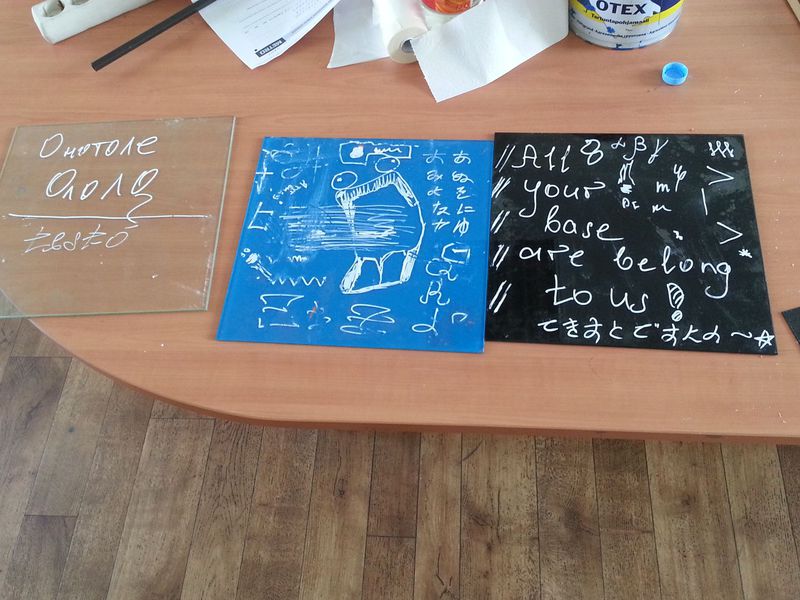

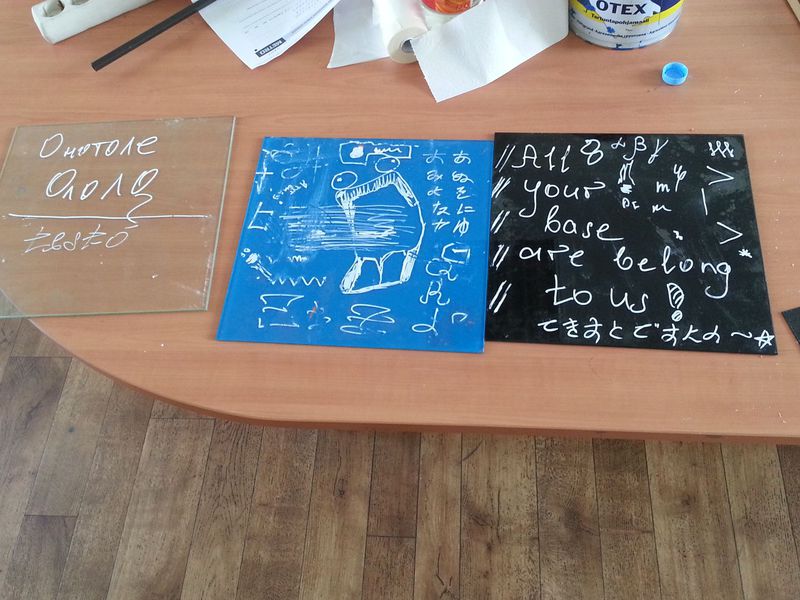

On Habré more than once and not two articles were published on how to make your ideal writing board. We have also tried to recreate these boards more than once or twice. At first, a vinyl film board was chosen as the simplest, cheapest, and most logical solution. The results were good, but not enough, because the board is terribly washable (only alcohol, water has almost no effect) and does not look very neat. Although, perhaps, we badly picked up the film. After the film, we decided to build a glass board with opposite contrast. The background color is blue. The main methods of implementation are either painting or colored substrate. For the purposes of testing and, in general, we have already purchased glass: three small squares 200 * 200 * 4, two huge and heavy sheets 2000 * 1500 * 4 and medium sizes 1000 * 1000 * 4. All glass was ordered with a polished edge to look neater and reduce the number of opportunities for injury.

')

The cardboard was good, but the difficulty of gluing was weak, but nevertheless the noticeable lines of the joint still forced to try painting. For painting was purchased 2 cans of acrylic paint in black and blue. Painting was completed quickly and fun, although there were many cries about the smell of paint. After that, they decided to make the smallest plank for use (meter per meter) and, after degreasing and laying out the walls with a newspaper, it was solemnly covered with five layers of paint.

It was found that the spray paint, in addition to the terrible stench, also scatters throughout the office in the form of the smallest dust that accumulates on everything that can settle. After painting, a blue stripe formed under the door, which, fortunately, was promptly noticed and eliminated.

Color and quality of painting had to all programmers and designers to taste, but then a new project came over and the board was put aside for about a month. When, after a month, we decided to continue, we found that acrylic spray paint has a fairly low adhesion to glass and, despite the degreasing of the surface, in some places began to move away from it. Moreover, the not very large board (meter per meter) was quite noticeable uneven painting and this despite the fact that the paint was applied in 3 layers. From spray painting options also had to be abandoned.

After a brief shastanya on construction forums, it turned out that some primers have good adhesion to glass. In the next building site they advised Tikkurila Otex, which was successfully purchased and otcolerovana in color M358.

Then everything went pretty fast. With the help of acetone acrylic paint shot in flight. Even a drop of acetone was enough for her to start swimming. After that, the surface went skimming and began the process of painting. The paint was gradually poured into the bath and neatly applied to the glass that was leaning against the wall. The primer was so thick that with careful application it did not flow down completely and dried, which is pleasant, rather quickly. In about 2.5 hours, we applied 3 layers and this was limited. After that, the board was left to dry for 2 days.

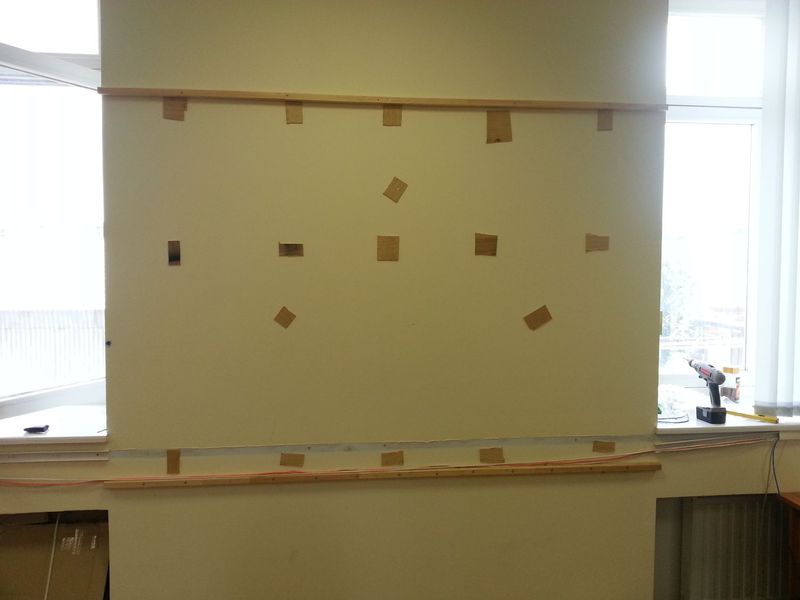

After, or rather, during drying, questions began to appear about how we will fix the board to the wall. I wanted to make it simple, fast and relatively neat and at the same time so that the wall did not collapse, because Giprok is giprok. As a result of our research, nylon dowels along the hyproc were found in the same building site, which, which was especially nice, did not require prior reaming of the wall.

Also, there were found quite a neat type of wooden bars measuring 20 * 20 * 2200 with rounded edges and not bad polished. As a result, these bars and it was decided to use as a frame.

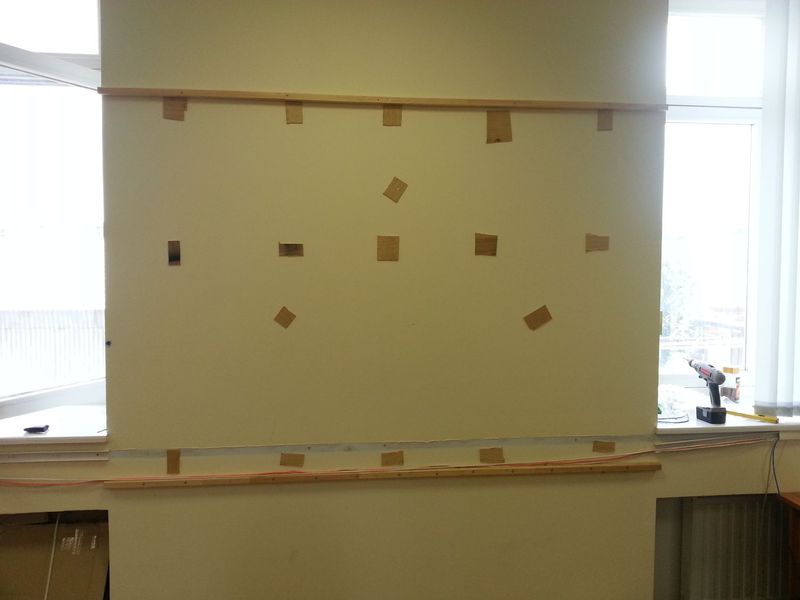

The mass of glass 2000 * 1500 * 4, based on the specific mass of glass 2700 kg / m3, turned out to be about 30 kg, which is quite a lot. The load on dowels is 10 kg for tearing, 25 for shear, and considering that the load will not be distributed ideally, and maybe someone will accidentally rest and we plan to attach small shelves, it was decided to consider it to be 1/3 nominal load and provide for its threefold excess , which gave us 11 dowels, which we successfully rounded to 12. The bars were laid out, drilled and finally screwed to the wall with screws.

The next task was not to allow the glass to fit snugly against the wall, since in this case, the glass may work like a wedge and in some perspective pull the bars out of the wall.

After searching, a small sheet of plywood was found, which became the fact that pushed the glass away from the wall. He was quickly sawn into a large number of uneven pieces that were attached to a wall with double-sided tape.

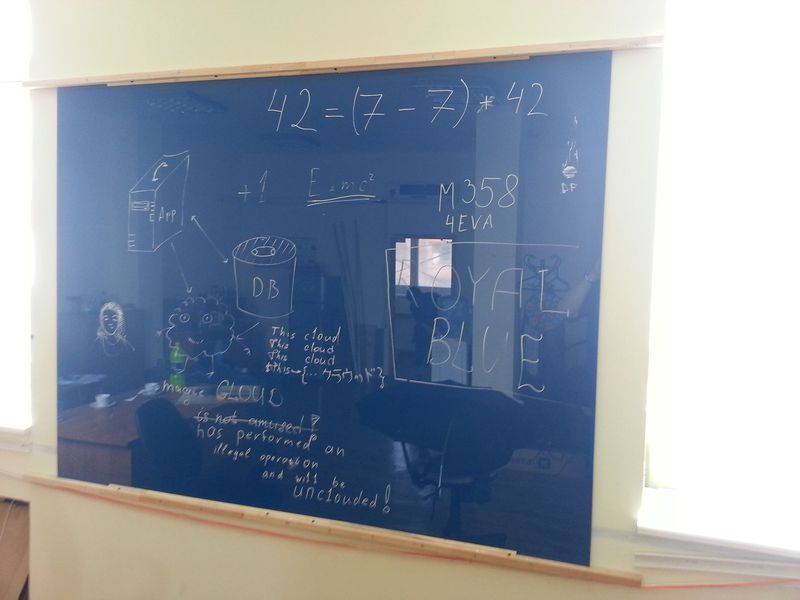

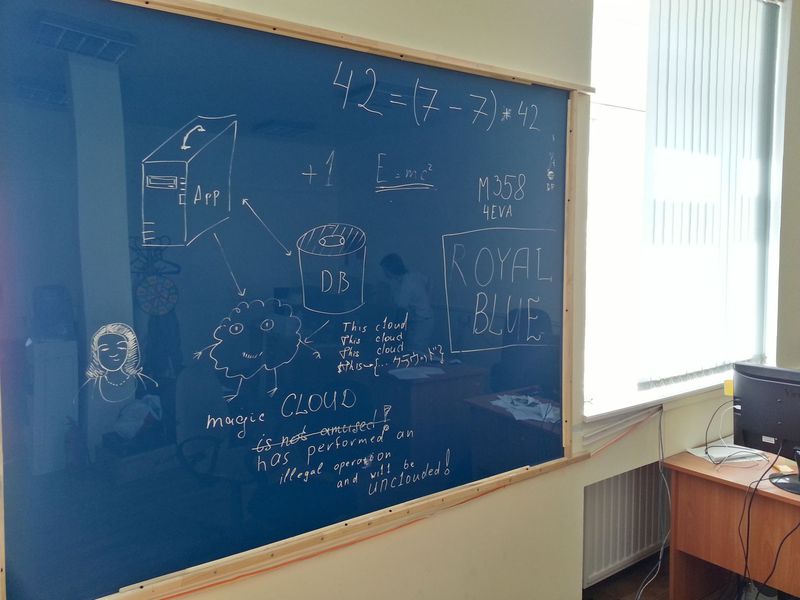

Further, the glass was set in place and secured at the top and bottom with a bead and small screws.

After that, to eliminate the horizontal course of the glass (it was slightly arched under its weight and sagged when pressed), vertical bars were made.

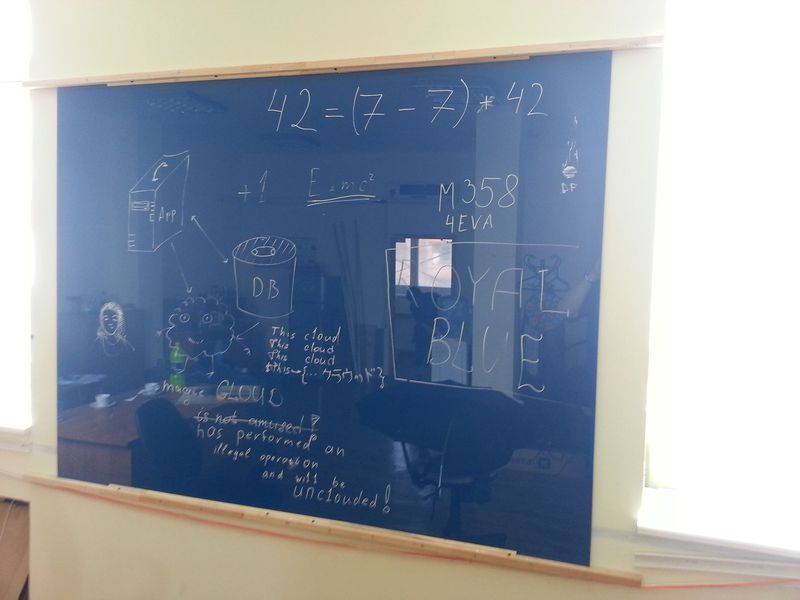

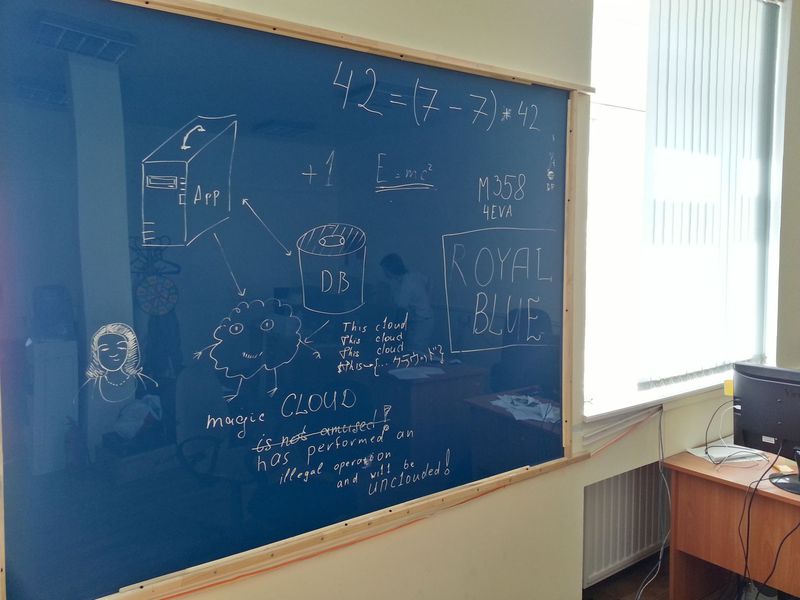

As a result of all these actions, we believe that our board is ready for use.

According to the results of weekly use, I would like to say that the board looks very good, is readable, it is great to write on it with a chalk marker, and it is erased with just a hand or a rag.

Speaking of markers, even at the stage of selecting the material of the board, the question arose what to write. After a brief Internet hustle and hundreds of permanent markers found for sale, which, if erased, the smell of acetone / solvent will stand on the whole office, we found chalk markers, which are most often used for writing on LED boards. A copy of such a marker was found in a nearby office supply store and allowed for “production testing”. His white lines and visible in the photos. However, as it turned out, in our city it is very, very difficult to find on the market at least some choice of these markers. Therefore, a quite good seller was found on ibei who delivers reasonably inexpensive tokens from China for free. We are waiting for them and we hope that we will have them soon.

Summing up, I would like to touch on the price of one board.

Materials:

Total: 6250 p.

Works about 6 hours in total.

As a result, we have: cost at the level of a cheap marker board 100 * 150, but at the same time a substantially large surface, contrast, durability and of course the joy that the board was made by hand.

On Habré more than once and not two articles were published on how to make your ideal writing board. We have also tried to recreate these boards more than once or twice. At first, a vinyl film board was chosen as the simplest, cheapest, and most logical solution. The results were good, but not enough, because the board is terribly washable (only alcohol, water has almost no effect) and does not look very neat. Although, perhaps, we badly picked up the film. After the film, we decided to build a glass board with opposite contrast. The background color is blue. The main methods of implementation are either painting or colored substrate. For the purposes of testing and, in general, we have already purchased glass: three small squares 200 * 200 * 4, two huge and heavy sheets 2000 * 1500 * 4 and medium sizes 1000 * 1000 * 4. All glass was ordered with a polished edge to look neater and reduce the number of opportunities for injury.

')

The cardboard was good, but the difficulty of gluing was weak, but nevertheless the noticeable lines of the joint still forced to try painting. For painting was purchased 2 cans of acrylic paint in black and blue. Painting was completed quickly and fun, although there were many cries about the smell of paint. After that, they decided to make the smallest plank for use (meter per meter) and, after degreasing and laying out the walls with a newspaper, it was solemnly covered with five layers of paint.

It was found that the spray paint, in addition to the terrible stench, also scatters throughout the office in the form of the smallest dust that accumulates on everything that can settle. After painting, a blue stripe formed under the door, which, fortunately, was promptly noticed and eliminated.

Color and quality of painting had to all programmers and designers to taste, but then a new project came over and the board was put aside for about a month. When, after a month, we decided to continue, we found that acrylic spray paint has a fairly low adhesion to glass and, despite the degreasing of the surface, in some places began to move away from it. Moreover, the not very large board (meter per meter) was quite noticeable uneven painting and this despite the fact that the paint was applied in 3 layers. From spray painting options also had to be abandoned.

After a brief shastanya on construction forums, it turned out that some primers have good adhesion to glass. In the next building site they advised Tikkurila Otex, which was successfully purchased and otcolerovana in color M358.

Then everything went pretty fast. With the help of acetone acrylic paint shot in flight. Even a drop of acetone was enough for her to start swimming. After that, the surface went skimming and began the process of painting. The paint was gradually poured into the bath and neatly applied to the glass that was leaning against the wall. The primer was so thick that with careful application it did not flow down completely and dried, which is pleasant, rather quickly. In about 2.5 hours, we applied 3 layers and this was limited. After that, the board was left to dry for 2 days.

After, or rather, during drying, questions began to appear about how we will fix the board to the wall. I wanted to make it simple, fast and relatively neat and at the same time so that the wall did not collapse, because Giprok is giprok. As a result of our research, nylon dowels along the hyproc were found in the same building site, which, which was especially nice, did not require prior reaming of the wall.

Also, there were found quite a neat type of wooden bars measuring 20 * 20 * 2200 with rounded edges and not bad polished. As a result, these bars and it was decided to use as a frame.

The mass of glass 2000 * 1500 * 4, based on the specific mass of glass 2700 kg / m3, turned out to be about 30 kg, which is quite a lot. The load on dowels is 10 kg for tearing, 25 for shear, and considering that the load will not be distributed ideally, and maybe someone will accidentally rest and we plan to attach small shelves, it was decided to consider it to be 1/3 nominal load and provide for its threefold excess , which gave us 11 dowels, which we successfully rounded to 12. The bars were laid out, drilled and finally screwed to the wall with screws.

The next task was not to allow the glass to fit snugly against the wall, since in this case, the glass may work like a wedge and in some perspective pull the bars out of the wall.

After searching, a small sheet of plywood was found, which became the fact that pushed the glass away from the wall. He was quickly sawn into a large number of uneven pieces that were attached to a wall with double-sided tape.

Further, the glass was set in place and secured at the top and bottom with a bead and small screws.

After that, to eliminate the horizontal course of the glass (it was slightly arched under its weight and sagged when pressed), vertical bars were made.

As a result of all these actions, we believe that our board is ready for use.

Results

According to the results of weekly use, I would like to say that the board looks very good, is readable, it is great to write on it with a chalk marker, and it is erased with just a hand or a rag.

Speaking of markers, even at the stage of selecting the material of the board, the question arose what to write. After a brief Internet hustle and hundreds of permanent markers found for sale, which, if erased, the smell of acetone / solvent will stand on the whole office, we found chalk markers, which are most often used for writing on LED boards. A copy of such a marker was found in a nearby office supply store and allowed for “production testing”. His white lines and visible in the photos. However, as it turned out, in our city it is very, very difficult to find on the market at least some choice of these markers. Therefore, a quite good seller was found on ibei who delivers reasonably inexpensive tokens from China for free. We are waiting for them and we hope that we will have them soon.

Summing up, I would like to touch on the price of one board.

Materials:

- Primer Otex + tinting - 1000r.

- Obziryrka - 100r.

- Dowels are 50 pcs. - 150r.

- Universal screws 50 * 4.5 50pcs. - 50r.

- Roller, Bath - 700r.

- 4 rolls of toilet paper - 100 rubles.

- Glass 4 * 2000 * 1500 with polished edges - 4000r.

- Wooden bar 20x20x2200 4pcs - 150r.

Total: 6250 p.

Works about 6 hours in total.

As a result, we have: cost at the level of a cheap marker board 100 * 150, but at the same time a substantially large surface, contrast, durability and of course the joy that the board was made by hand.

Source: https://habr.com/ru/post/147244/

All Articles