Project Fab Lab - Internet for atoms

It is no secret that the means of production are becoming more accessible to individuals. This is evidenced by the emergence of such low-cost machines as a Makerbot 3D printer, and such “garage” startups as Local Motors (this topic is covered in detail in this article ). As a result, the production becomes personalized. This article tells about a project to create an infrastructure that opens up access to the means of production for the population according to the Fab Lab model (fabrication / fabulous laboratory) , its future in the world and Russia.

A new industrial revolution began in 1998 in Boston. When the professor at the Massachusetts Institute of Technology (MIT) Neil Gershenfeld first organized a course for students called “How to do almost everything” (“How to make almost everything”). As part of the training, students had to master the modern and expensive equipment of the MIT laboratory to implement their research projects.

What was his surprise when more than 100 came to the first lesson in the laboratory with a capacity of 10 people. But the students did not come to improve their professional qualifications and not to work on their graduation projects. They used MIT equipment worth several million dollars to put their own ideas into life, to create new things that would seem completely useless to the average person.

')

1. Bag for screams . Have you encountered a situation when you want to shout in a public place, but the rules of conduct do not allow this? So this invention is for you. Shout into your bag! It completely isolates the sound, moreover, allows it to be recorded, so that later, in a deserted place, using the playback function, it can release emotions into the wild.

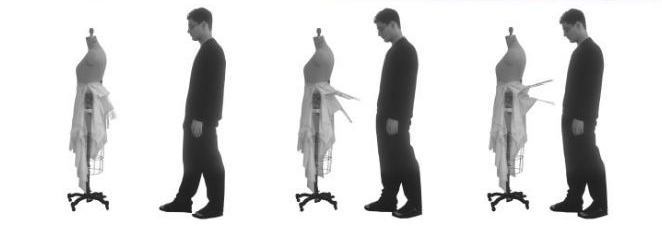

2. Dress that guards your personal space . Tired of annoying gentlemen? A smart dress, with the help of sensors installed on it, feels the approach of an unexpected guest, and by means of a mechanical mechanism raises protective floors.

3. An alarm clock to fight . To turn off this alarm, you certainly have to wake up, and even do the exercises.

4. Internet browser for a parrot.

It is unlikely that such goods will ever be in massive demand. So, their production is inappropriate for an industrial company. That is, if MIT students had not gained access to the lab's production capabilities, these unique and original things would probably never have been created.

The technologies of the end of the 20th century allow us today to freely express ourselves in literature, music, photography. The Internet has provided each of us with the opportunity to be a writer, publicist, actor, musician and director, without leaving home. As Professor Gershenfeld says: “The digital revolution has come true, we no longer need to say this, what will happen next - this is a production revolution.” But are we ready for a completely new form of creativity - “the creation of things” , a change in the material world around us? The experiment of Professor Gershenfeld showed: there is a need.

However, in order to open up personal production for the population, you need a tool that must combine ease of operation (working with it does not require fundamental knowledge of material processing technology and special engineering education) and broad production capabilities (working with various materials: wood , plastic, acrylic, metal, leather, etc.), it must produce not only the external form, but also electronic filling, in order to make new things "live". If we draw an analogy with computers, modern production equipment is the first computer, weighing tons and requiring a large number of personnel for maintenance, and we need a personal computer, in our case “personal manufacturer”. Such a tool is - this is Fab Lab. Fab Lab is an open digital laboratory , it is the best of the existing personal production tools.

In 2001, under the social program in the USA, the first laboratory Fab Lab was created by the MIT Bit and Atom Center (Fab is the abbreviated from English fabrication - production or fabulous - incredible). It included equipment such as milling machines that allow mechanical machining of materials, a 3D printer, for printing plastic parts, a tool for creating printed circuit boards, a plotter for cutting vinyl, Arduino boards, and other similar means of production. Software integrating all of these technologies into a single process was written by MIT staff. This laboratory was a simplified version of the MIT industrial laboratory at a cost of not more than 100,000 USD . This project was so successful that the network of laboratories Fab Lab has grown around the world - today it is more than a hundred laboratories-factories around the world, from Ghana and Afghanistan to Spain and the United States. And every year their number doubles.

Fab Lab teaches the skills needed to develop and produce new products (from 3D modeling and graphics, electronics and programming to project management), but unlike classical educational institutions, theory is taught as the need arises. Of course, Fab Lab conducts both short-term (up to a week) and long-term (up to six months) training programs in which MIT professors and gurus from major laboratories in the world give lectures. But most of the training takes place in the process of working on their own project, the staff of the laboratory, other visitors and experts of the international network act as consultants.

As a result of such communication and constant interaction, in each successful Fab Lab a community of developers with a wide range of professional skills is formed. It is this community of creative and workable people - the main resource of the laboratory. Having formed such a resource, Fab Lab invests it in the development of commercial products, the implementation of technically complex, non-trivial orders, and innovative consulting. For example, in Fab Lab Barcelona under the order was designed balloon design for tourism in the stratosphere.

The potential of Fab Lab lies in the field of a completely new market segment. This is not a prototyping center (gave the order - received a model), not shared centers (paid for equipment rental). At the same time, this is not an innovation consulting firm (set the task - received development) and not an educational institution in its pure form. The scope of use of Fab Lab lies between these segments, like sand, which fills the space between large stones. And its "trick" is in the ability to be flexible in the disposal of resources, to find a compromise with customers, to look for alternative ways to interact with developers, but at the same time not be afraid to take on complex non-trivial tasks and solve them.

The main achievement and priority of Fab Lab is to overcome the psychological barrier of the population from “this is impossible; to solve this problem I need to buy a machine for several million dollars and study in a technical university for six years” to “I will do it myself at Fab Lab using milling machine, or hacksaw and electrical tape ".

The social effect of Fab Lab is to help develop innovative products, create new jobs, improve the skills of the population, and equip people with technology to solve their social problems on their own.

Each laboratory is an element of urban infrastructure that solves the tasks of its community. For example, in Afghanistan, a local network of Wifi towers was created to provide the population with Internet. In India, there are refrigerators for cars so that meat does not deteriorate during transportation. In Spain (Barcelona), the laboratory serves architects and designers, for example, to create a prototype of a new house, a new shoe model, or a three-dimensional map of Barcelona.

If you walk along the seafront of Barcelona, visit Fab @ House . This is a house created by the Fab Lab Barcelona team with the participation of Fab Lab MIT and the Architectural University of Catalonia on the Fab Lab equipment. This is not just a static design, it is based on a dynamic model, depending on the geographical location of the house, its shape changes to optimize the heat distribution inside and the time the sun hits the solar panels. This house is fully self-sufficient in electricity, even in winter (in Barcelona in winter +10), and even allows you to sell excess electricity back into the network. By the way, the drawings of this house are freely available, you can collect the same for yourself in your local Fab Lab.

The Internet and personal computers have changed our lives. Having access to the free exchange of information, we wrote Wikipedia, the largest encyclopedia in the world, we drew the maps of OpenStreetMap, we are looking for extraterrestrial life using the SETI @ home project. What will we do when we get free access to tools for changing the material world?

Soon, Fab Lab laboratories will appear in Russia. In St. Petersburg, teams of SPBGPU (Polytech), NRU ITMO and the TVN Foundation work on the Fab Lab project. But as mentioned above, Fab Lab is, first and foremost, the people who form its community, their needs and ideas. Fab Lab is also a place for interaction of specialists of different skills and interests: programming, electronics development, design, architecture, modeling, etc. It is the combination of these skills and creation “at the junction” that makes the design clever, and the architecture alive.

If you have ideas about what you want to do in the Fab Lab, or you would like to become a member of its community - write, we gather a team of like-minded people. Don't worry, atoms are new bits.

Lecture "Digital production laboratories of Neil Gershenfeld in St. Petersburg"

Watch the video

Fab lab mit

Fab Lab Barcelona

Fab Lab Manchester

Our group VKontakte

Course at MIT

A new industrial revolution began in 1998 in Boston. When the professor at the Massachusetts Institute of Technology (MIT) Neil Gershenfeld first organized a course for students called “How to do almost everything” (“How to make almost everything”). As part of the training, students had to master the modern and expensive equipment of the MIT laboratory to implement their research projects.

What was his surprise when more than 100 came to the first lesson in the laboratory with a capacity of 10 people. But the students did not come to improve their professional qualifications and not to work on their graduation projects. They used MIT equipment worth several million dollars to put their own ideas into life, to create new things that would seem completely useless to the average person.

')

First projects

1. Bag for screams . Have you encountered a situation when you want to shout in a public place, but the rules of conduct do not allow this? So this invention is for you. Shout into your bag! It completely isolates the sound, moreover, allows it to be recorded, so that later, in a deserted place, using the playback function, it can release emotions into the wild.

2. Dress that guards your personal space . Tired of annoying gentlemen? A smart dress, with the help of sensors installed on it, feels the approach of an unexpected guest, and by means of a mechanical mechanism raises protective floors.

3. An alarm clock to fight . To turn off this alarm, you certainly have to wake up, and even do the exercises.

4. Internet browser for a parrot.

It is unlikely that such goods will ever be in massive demand. So, their production is inappropriate for an industrial company. That is, if MIT students had not gained access to the lab's production capabilities, these unique and original things would probably never have been created.

The technologies of the end of the 20th century allow us today to freely express ourselves in literature, music, photography. The Internet has provided each of us with the opportunity to be a writer, publicist, actor, musician and director, without leaving home. As Professor Gershenfeld says: “The digital revolution has come true, we no longer need to say this, what will happen next - this is a production revolution.” But are we ready for a completely new form of creativity - “the creation of things” , a change in the material world around us? The experiment of Professor Gershenfeld showed: there is a need.

Network development

However, in order to open up personal production for the population, you need a tool that must combine ease of operation (working with it does not require fundamental knowledge of material processing technology and special engineering education) and broad production capabilities (working with various materials: wood , plastic, acrylic, metal, leather, etc.), it must produce not only the external form, but also electronic filling, in order to make new things "live". If we draw an analogy with computers, modern production equipment is the first computer, weighing tons and requiring a large number of personnel for maintenance, and we need a personal computer, in our case “personal manufacturer”. Such a tool is - this is Fab Lab. Fab Lab is an open digital laboratory , it is the best of the existing personal production tools.

In 2001, under the social program in the USA, the first laboratory Fab Lab was created by the MIT Bit and Atom Center (Fab is the abbreviated from English fabrication - production or fabulous - incredible). It included equipment such as milling machines that allow mechanical machining of materials, a 3D printer, for printing plastic parts, a tool for creating printed circuit boards, a plotter for cutting vinyl, Arduino boards, and other similar means of production. Software integrating all of these technologies into a single process was written by MIT staff. This laboratory was a simplified version of the MIT industrial laboratory at a cost of not more than 100,000 USD . This project was so successful that the network of laboratories Fab Lab has grown around the world - today it is more than a hundred laboratories-factories around the world, from Ghana and Afghanistan to Spain and the United States. And every year their number doubles.

Fab Lab teaches the skills needed to develop and produce new products (from 3D modeling and graphics, electronics and programming to project management), but unlike classical educational institutions, theory is taught as the need arises. Of course, Fab Lab conducts both short-term (up to a week) and long-term (up to six months) training programs in which MIT professors and gurus from major laboratories in the world give lectures. But most of the training takes place in the process of working on their own project, the staff of the laboratory, other visitors and experts of the international network act as consultants.

As a result of such communication and constant interaction, in each successful Fab Lab a community of developers with a wide range of professional skills is formed. It is this community of creative and workable people - the main resource of the laboratory. Having formed such a resource, Fab Lab invests it in the development of commercial products, the implementation of technically complex, non-trivial orders, and innovative consulting. For example, in Fab Lab Barcelona under the order was designed balloon design for tourism in the stratosphere.

The potential of Fab Lab lies in the field of a completely new market segment. This is not a prototyping center (gave the order - received a model), not shared centers (paid for equipment rental). At the same time, this is not an innovation consulting firm (set the task - received development) and not an educational institution in its pure form. The scope of use of Fab Lab lies between these segments, like sand, which fills the space between large stones. And its "trick" is in the ability to be flexible in the disposal of resources, to find a compromise with customers, to look for alternative ways to interact with developers, but at the same time not be afraid to take on complex non-trivial tasks and solve them.

The main achievement and priority of Fab Lab is to overcome the psychological barrier of the population from “this is impossible; to solve this problem I need to buy a machine for several million dollars and study in a technical university for six years” to “I will do it myself at Fab Lab using milling machine, or hacksaw and electrical tape ".

Signed projects

The social effect of Fab Lab is to help develop innovative products, create new jobs, improve the skills of the population, and equip people with technology to solve their social problems on their own.

Each laboratory is an element of urban infrastructure that solves the tasks of its community. For example, in Afghanistan, a local network of Wifi towers was created to provide the population with Internet. In India, there are refrigerators for cars so that meat does not deteriorate during transportation. In Spain (Barcelona), the laboratory serves architects and designers, for example, to create a prototype of a new house, a new shoe model, or a three-dimensional map of Barcelona.

If you walk along the seafront of Barcelona, visit Fab @ House . This is a house created by the Fab Lab Barcelona team with the participation of Fab Lab MIT and the Architectural University of Catalonia on the Fab Lab equipment. This is not just a static design, it is based on a dynamic model, depending on the geographical location of the house, its shape changes to optimize the heat distribution inside and the time the sun hits the solar panels. This house is fully self-sufficient in electricity, even in winter (in Barcelona in winter +10), and even allows you to sell excess electricity back into the network. By the way, the drawings of this house are freely available, you can collect the same for yourself in your local Fab Lab.

The future of personal production

The Internet and personal computers have changed our lives. Having access to the free exchange of information, we wrote Wikipedia, the largest encyclopedia in the world, we drew the maps of OpenStreetMap, we are looking for extraterrestrial life using the SETI @ home project. What will we do when we get free access to tools for changing the material world?

Soon, Fab Lab laboratories will appear in Russia. In St. Petersburg, teams of SPBGPU (Polytech), NRU ITMO and the TVN Foundation work on the Fab Lab project. But as mentioned above, Fab Lab is, first and foremost, the people who form its community, their needs and ideas. Fab Lab is also a place for interaction of specialists of different skills and interests: programming, electronics development, design, architecture, modeling, etc. It is the combination of these skills and creation “at the junction” that makes the design clever, and the architecture alive.

If you have ideas about what you want to do in the Fab Lab, or you would like to become a member of its community - write, we gather a team of like-minded people. Don't worry, atoms are new bits.

Links

Lecture "Digital production laboratories of Neil Gershenfeld in St. Petersburg"

Watch the video

Fab lab mit

Fab Lab Barcelona

Fab Lab Manchester

Our group VKontakte

Source: https://habr.com/ru/post/147080/

All Articles