Rescue CD / DVD Polished

The worst enemy of a CD / DVD is scratching. Because of one small scratch, you can lose a backup or an important file recorded 10 years ago. But if the disc is no longer readable - there is a rather high chance of saving it by polishing the working surface. See the assembly instructions for homemade polisher.

With this gadget, you can even open a small business on the "recovery of information from the disks." The machine works quickly and can recover dozens of disks per hour. Five minutes is enough for perfect polishing of one disc.

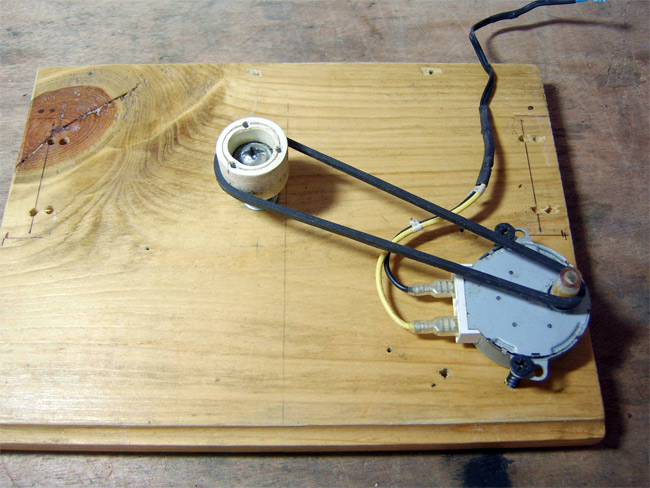

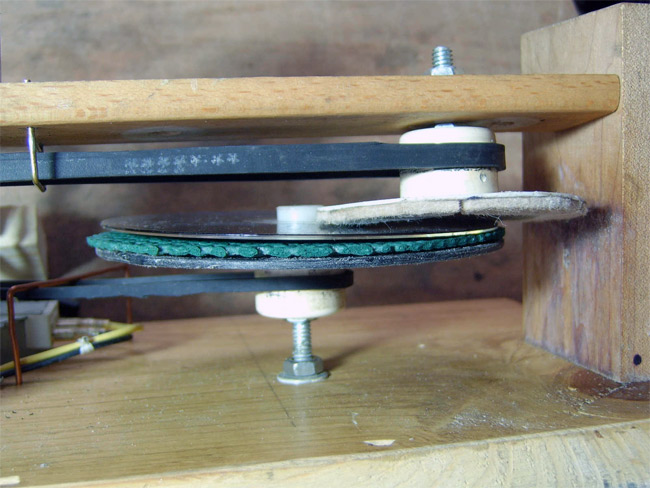

The design consists of a pair of motors: one slowly rotates the disk, turned upside down, and the second motor rotates the scrub head. For the lower motor, the author took the motor for 5 rpm from the microwave and rubber harnesses from a vacuum cleaner.

')

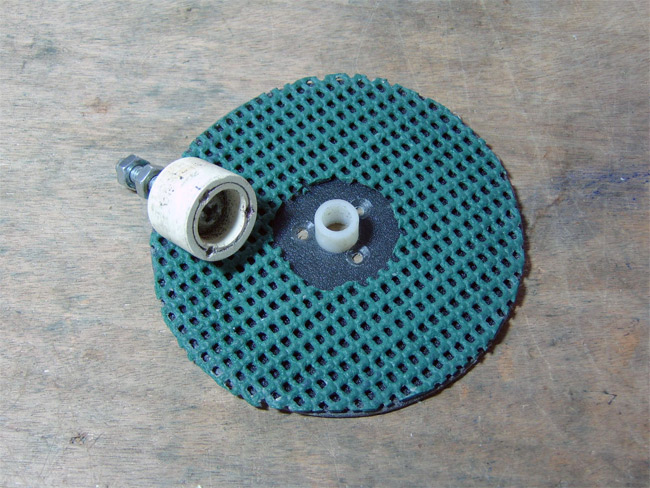

For mounting the disc and polishing pad, you can use roller skate bearings, the disc stand is made of any plastic with a soft pad.

The cleaning pad is made of a thin plastic base, covered with felt.

The motor for the polishing pad, the author took from the electric screwdriver B & D 12B for two dollars. It turned out that it can work on 24V, and for this motor you need great momentum, because the pad would be good to press to the disk.

The main rule - the rotation of the pillow should be perpendicular to the location of the tracks. The direction is indicated by arrows in the illustration.

The pad should not necessarily be pressed against the disk with the entire surface. That's quite normal, the front of the cleaning pad will do all the work.

Do not forget about the polishing gel, with it is better not to cheap.

Source: https://habr.com/ru/post/146483/

All Articles