Eco-friendly and energy-efficient printing technologies KYOCERA

Today, all and sundry talk about the transition to green technology. But it is always interesting to see, not what they say, but what they do. Due to unique technologies, KYOCERA managed to significantly reduce the amount of waste generated. How?

First, KYOCERA has created a print-free printing technology.

Secondly, increased component life.

In KYOCERA devices, the cartridge is fixed separately, and the only consumable that needs replacing throughout the life of the devices is toner. If a conventional cartridge is assembled from more than 60 components, then the KYOCERA toner container consists of only 4. In addition, the cartridge of a conventional laser printer should be replaced, the toner container is barely empty, even if the drum and other components have not yet reached the service life. KYOCERA's ECOSYS technology avoids the formation of “non-essential” wastes, as well as reduces carbon dioxide emissions during the production and transportation of finished products.

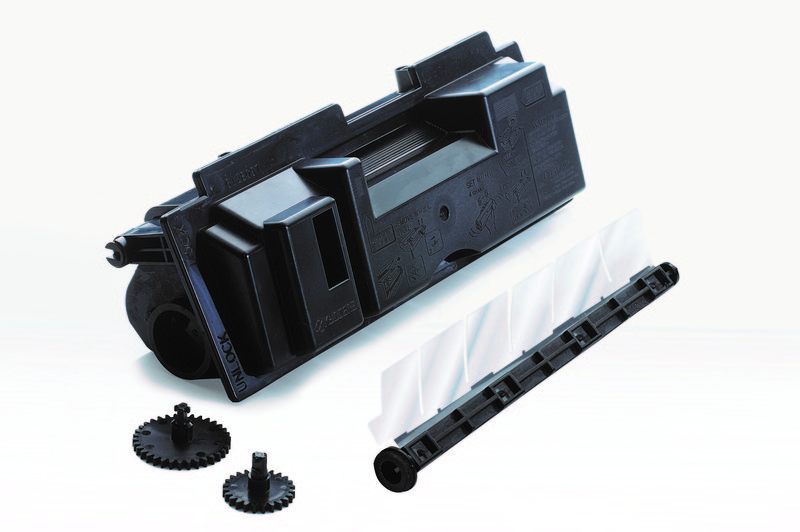

Conventional cartridge consisting of 60 components

')

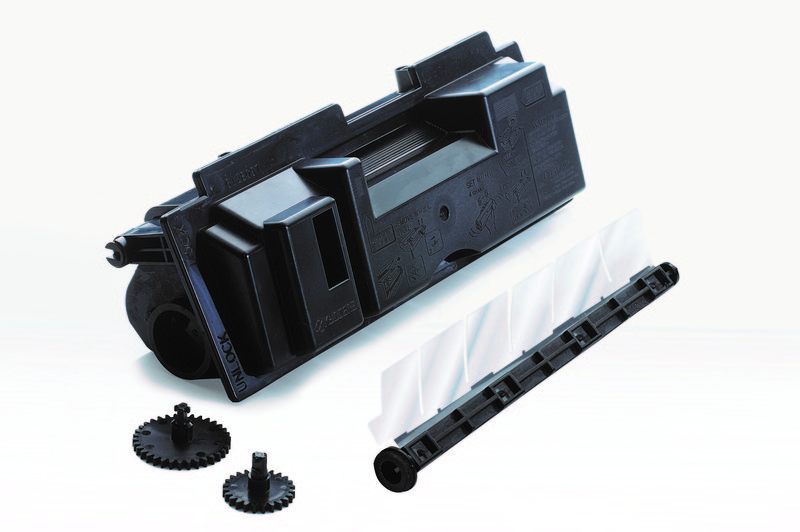

Toner container KYOCERA

Moreover, in the newest color and black-and-white high-speed MFPs of the TASKalfa series *, instead of the conventional fuser lamp, an induction-heating fuser is used. Using an induction heating fuser not only shortens the warm-up time of the device, but also reduces power consumption. This is due to the fact that the lamp consumes more energy than an induction heater. All this makes printing with KYOCERA an energy efficient process.

* TASKalfa 6500i / 8000i, TASKalfa 3050ci / 3550ci / 4550ci / 5550ci / 6550ci / 7550ci

First, KYOCERA has created a print-free printing technology.

Secondly, increased component life.

In KYOCERA devices, the cartridge is fixed separately, and the only consumable that needs replacing throughout the life of the devices is toner. If a conventional cartridge is assembled from more than 60 components, then the KYOCERA toner container consists of only 4. In addition, the cartridge of a conventional laser printer should be replaced, the toner container is barely empty, even if the drum and other components have not yet reached the service life. KYOCERA's ECOSYS technology avoids the formation of “non-essential” wastes, as well as reduces carbon dioxide emissions during the production and transportation of finished products.

Conventional cartridge consisting of 60 components

')

Toner container KYOCERA

Moreover, in the newest color and black-and-white high-speed MFPs of the TASKalfa series *, instead of the conventional fuser lamp, an induction-heating fuser is used. Using an induction heating fuser not only shortens the warm-up time of the device, but also reduces power consumption. This is due to the fact that the lamp consumes more energy than an induction heater. All this makes printing with KYOCERA an energy efficient process.

* TASKalfa 6500i / 8000i, TASKalfa 3050ci / 3550ci / 4550ci / 5550ci / 6550ci / 7550ci

Source: https://habr.com/ru/post/145159/

All Articles