At Harvard, robots are collected as children's folding books

In the Harvard laboratory, micro-robotics have developed a new technology for the mass production of micro-robots. The blank for making a robot consists of several layers of different materials glued together in a “sandwich”, in which the details of the robot and additional hinges and supports serving as “scaffolding” for assembly are cut out by a laser. To get from the workpiece of the robot, it is folded, fixed in the folded state and cut off more unnecessary auxiliary elements.

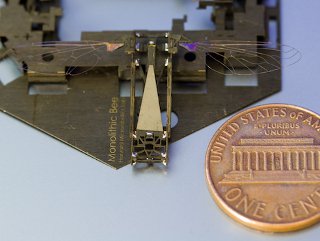

In the Harvard laboratory, micro-robotics have developed a new technology for the mass production of micro-robots. The blank for making a robot consists of several layers of different materials glued together in a “sandwich”, in which the details of the robot and additional hinges and supports serving as “scaffolding” for assembly are cut out by a laser. To get from the workpiece of the robot, it is folded, fixed in the folded state and cut off more unnecessary auxiliary elements.A laboratory-created prototype of a flying robot bee (Monolithic Bee or Mobee) weighs 90 milligrams, and the “sandwich” for its assembly consists of eighteen layers of carbon, titanium, copper, ceramics, and a flexible plastic film. The assembly of the robot takes place in one movement, like a children's folding book, its body is fixed in the assembled position with the help of tiny droplets of solder, fastening the copper pads in the places of the folds.

This technology can be used to assemble any complex electromechanical devices. Electrical circuits, sensors, and other components can be embedded in the sandwich. In a similar way, multi-layer printed circuit boards have been made for a long time, so it will be relatively easy to establish mass production of such devices, scientists believe.

')

Designing folding devices is much more complicated than conventional ones - instead of a set of relatively simple parts, you have to deal with a complex three-dimensional puzzle, but the production and assembly of finished products in a new way more than compensate for this complexity.

Source - Harvard University .

Source: https://habr.com/ru/post/144791/

All Articles