Trikopter on Crius MultiWii controller

ATTENTION, the article is outdated, but it can still be used for informational purposes.

Inspired by the article with rcexplorer on the simple construction of a copter ( here is my translation ), I also made myself a small flying unit with 3 motors, but with different brains and an aluminum base of rays instead of wood.

I will keep silent about some things, as they are described in detail in the last article .

The frame is made very simple. We take a piece of fiberglass or other similar thin and durable material, cut two parts of the central part of the desired size and, fastening the resulting parts with two third-party tape, drill 6 holes in them to fix the rays: 2 holes per beam, and each beam at an angle of 120 degrees. It is desirable to calculate in advance the distance from the axis of the motor to the center of the connection of the rays, otherwise there may be problems with the future tuning of the flight controller.

If you do not know where to find fiberglass, then you can always order on the website taydaelectronics.com, one square measuring 6 by 6 inches costs a little more than $ 1, but you need to buy at least 5 pieces to keep within the minimum weight of the package.

Now we need a lightweight and durable aluminum profile. As I was lazy to go shopping, and time was patient, I ordered a set of 4 beams , 25 cm long, each from the GoodLuckBuy website.

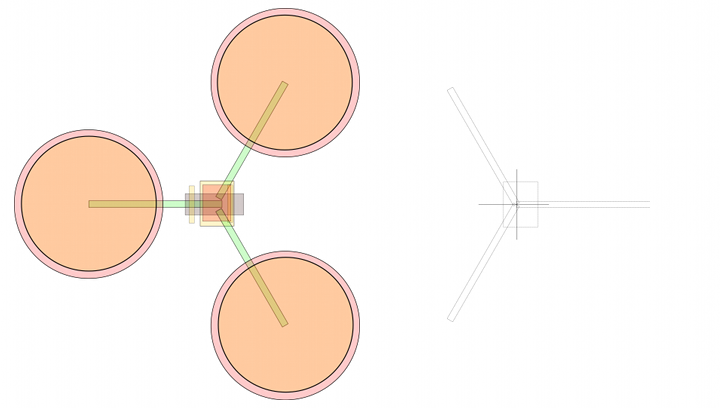

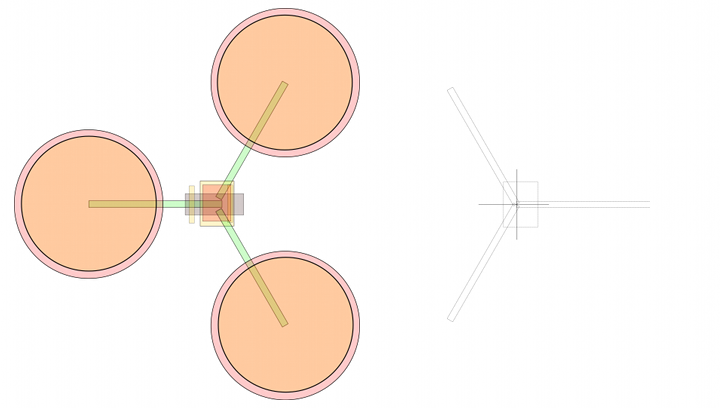

I usually estimate the location and dimensions in inkscape, then leave the contour, print and paste on the workpiece.

At the time of construction, I had only a small piece of foiled fiberglass, so it turned out two rectangles of size 65 by 85 mm. In which later 4 more holes were made for fastening the suspension with a battery and a camera.

The result was such a frame, fastened with plastic bolts and nuts, which also does not add up badly (later it will not be so beautiful, but still compact)

The most difficult and problematic place of the tricopter is a rotating mechanism of the rear motor, which serves to compensate for the rotation, as well as for turning. That's just because of him for a long time did not dare to build a "three rubles", but really wanted in view of the economy and the ability to easily fold the frame for transportation. As in David's article, I took these things :

But there was an error with the servo (I wanted to save a little, but I had to buy it twice), so the first version of the mechanism turned out to be quite large and heavy.

Therefore, I recommend immediately take the servos BMS-385DMAX, specified in the article David .

Note that the screed holding the swivel mechanism does not fall off, you should slightly bend the profile. I also recommend screwing a small piece of wood into the recess of the white block of the mechanism, as well as using 2-sided tape or glue.

')

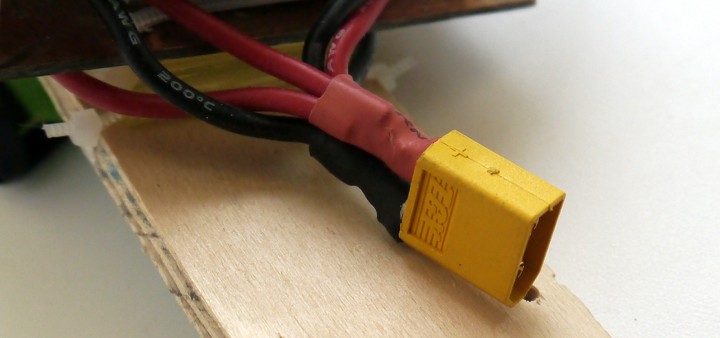

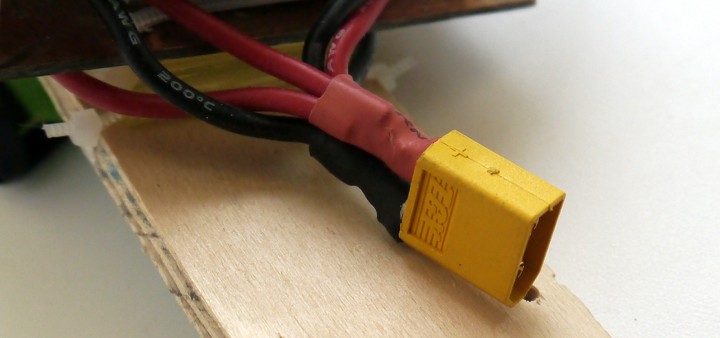

By tradition (and there was a house too ) HobbyKing BlueSeries 30A speed controllers and 20-22L motors. Speed controllers had to lengthen the power wires to conveniently remove the power connector , and even to reach the battery . And of course, you need to slightly change the settings of the speed controllers by turning on the Brake, increasing Timing to High and removing smooth acceleration (on different speed controllers there are different parameters, but on the whole, put everything so that it is faster).

The propellers are multidirectional , according to the rotations of the motors: the front left rotates clockwise, the front right counterclockwise, and the rear one, depending on your settings (I remind you that to change the direction of rotation, it is enough to change any 2 wires from the speed controller to the motor in some places).

Suspension in this case is just plywood, cut to the width of the battery. Velcro is glued to the plywood (the other part is on the battery) and at the same time an additional adhesive tape is inserted to securely attach the battery.

Silicone tubes are attached to the suspension through the screeds, other silicone tubes are attached to the frame on the screeds, and then fastened together to dampen the vibration on the camera.

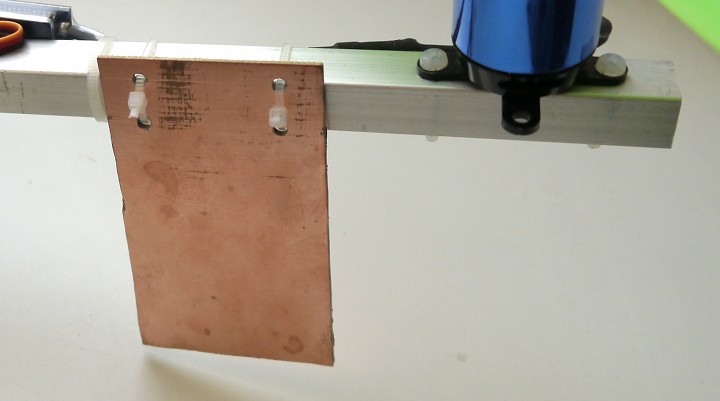

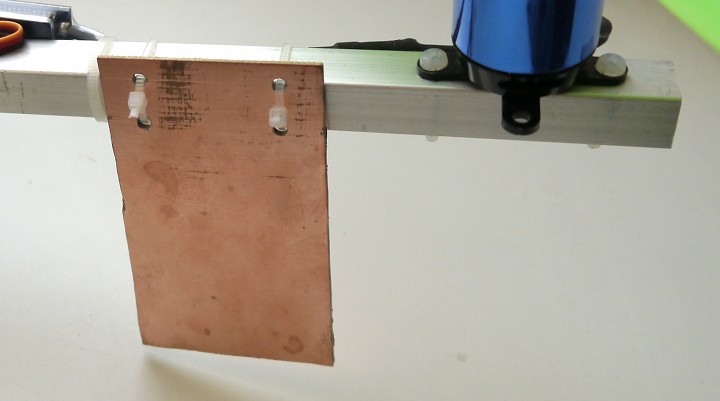

To prevent the copter from landing on the battery (which is extremely dangerous), 3 small rectangles can be cut out of PCB remnants and, by drilling holes in them, fasten them to the rays with ties.

With a relatively hard landing, the screeds fall off, quenching most of the fall energy, so the battery does not suffer (tested in a fall from 7 meters on the asphalt).

Not so long ago, a very cheap flight controller with atmega328p and a set of sensors appeared on the site goodluckbuy: a gyro + accelerometer for the Lite version and an additional barometer and compass for the Standart version . I took the Lite version for two reasons: the price (at the time of purchase, the difference was 2 times) and the senselessness of other sensors (the course holds perfectly without a compass, and holding the height with jumps + -2 meters on the bmp085 sensor does not inspire me).

After the purchase, I recommend otkovyryat all unnecessary and rinse the handkerchief in alcohol, as almost all the Chinese have left a lot of conductive dirt that closes the contacts and can just kill the controller.

Fasten the board and related equipment (receiver) to the frame with foam tape . It holds very firmly, and at the same time it eliminates vibrations a little. (Only do not fasten the antenna so if you are going to fly far).

The weight of the copter is about 800 grams, the flight time with a 2.2Ah battery and camera up to 200 grams is about 10 minutes, while the power reserve is still about 40-50%.

The iron part ends and the game begins with the software.

After the first connection of the board, it turned out that the flooded firmware is quite old, and with the sensor axes mixed up, i.e. You can even fly on this one. Therefore, download the Arduino IDE and the new firmware (do not download the dev!), And even better is the port from mahowik with a bunch of improvements.

Open through Arduino IDE sketch-firmware. The entire configuration is described in the config.h file (more details about most of the parameters and settings can be found here , in this article many trivia are omitted). For a tricopter we set the frame type #define TRI, the type of sensor board #define CRIUS_LITE and the filter for the gyro #define ITG3200_LPF_42HZ. And now in the Arduino IDE settings, select any 328p Arduinka and fill the resulting sketch.

Run MultiWiiConf for your system.

Since our rotary mechanism uses servo, which has properties to burn under heavy loads, it is better to find out and set limits for deviations of the serva. To do this, use the YAW stick on the control panel to reject the servo left and right and remember the maximum and minimum SERVO value in its extreme positions, and then enter these values in the config.h file

And reload the sketch into the controller. Now you can try to take off, but note that the copter will rotate, so stream the YAW channel on the console so that there are no rotations during takeoff and flights, and then go back to MultiWiiConf, look at this value in the SERVO field and change it to

ATTENTION! In the new firmware (2.0 and higher), similar trimming is done through the LCD screen or terminal, if you do not have either one or the other, you will have to change the code in Output.ino a little

Ready configuration file for my trikopter nekaka.com/d/sgNj8AXp2Y - maybe someone will come in handy.

Now you can configure the PID , add camera grip control, etc. , as well as add GPS support with hold and return home functions.

In fact, the construction and configuration will be a lot of incomprehensible and interesting. But the occupation of aircraft modeling is demanding, and the occupation of copters is twofold, especially if you are a programmer and you want to improve the code of one of the open source projects.

And in the conclusion of the video of the recent flight, during which the kopter was badly damaged, but was quickly repaired right there on the field (thanks to the screeds and plastic bolts).

The shooting was carried out with 2x devices: a quadrocopter with a GoPro camera and my tricopter with an onboard FPV camera, the picture with which was recorded on the ground on an old miniDV camera.

ps: if you have any questions - ask, I will update the article as much as possible.

Inspired by the article with rcexplorer on the simple construction of a copter ( here is my translation ), I also made myself a small flying unit with 3 motors, but with different brains and an aluminum base of rays instead of wood.

I will keep silent about some things, as they are described in detail in the last article .

Frame

The frame is made very simple. We take a piece of fiberglass or other similar thin and durable material, cut two parts of the central part of the desired size and, fastening the resulting parts with two third-party tape, drill 6 holes in them to fix the rays: 2 holes per beam, and each beam at an angle of 120 degrees. It is desirable to calculate in advance the distance from the axis of the motor to the center of the connection of the rays, otherwise there may be problems with the future tuning of the flight controller.

If you do not know where to find fiberglass, then you can always order on the website taydaelectronics.com, one square measuring 6 by 6 inches costs a little more than $ 1, but you need to buy at least 5 pieces to keep within the minimum weight of the package.

Now we need a lightweight and durable aluminum profile. As I was lazy to go shopping, and time was patient, I ordered a set of 4 beams , 25 cm long, each from the GoodLuckBuy website.

I usually estimate the location and dimensions in inkscape, then leave the contour, print and paste on the workpiece.

At the time of construction, I had only a small piece of foiled fiberglass, so it turned out two rectangles of size 65 by 85 mm. In which later 4 more holes were made for fastening the suspension with a battery and a camera.

The result was such a frame, fastened with plastic bolts and nuts, which also does not add up badly (later it will not be so beautiful, but still compact)

Swivel mechanism

The most difficult and problematic place of the tricopter is a rotating mechanism of the rear motor, which serves to compensate for the rotation, as well as for turning. That's just because of him for a long time did not dare to build a "three rubles", but really wanted in view of the economy and the ability to easily fold the frame for transportation. As in David's article, I took these things :

But there was an error with the servo (I wanted to save a little, but I had to buy it twice), so the first version of the mechanism turned out to be quite large and heavy.

Therefore, I recommend immediately take the servos BMS-385DMAX, specified in the article David .

Note that the screed holding the swivel mechanism does not fall off, you should slightly bend the profile. I also recommend screwing a small piece of wood into the recess of the white block of the mechanism, as well as using 2-sided tape or glue.

')

Speed controllers, motors and propellers

By tradition (and there was a house too ) HobbyKing BlueSeries 30A speed controllers and 20-22L motors. Speed controllers had to lengthen the power wires to conveniently remove the power connector , and even to reach the battery . And of course, you need to slightly change the settings of the speed controllers by turning on the Brake, increasing Timing to High and removing smooth acceleration (on different speed controllers there are different parameters, but on the whole, put everything so that it is faster).

The propellers are multidirectional , according to the rotations of the motors: the front left rotates clockwise, the front right counterclockwise, and the rear one, depending on your settings (I remind you that to change the direction of rotation, it is enough to change any 2 wires from the speed controller to the motor in some places).

Suspension, battery and rack

Suspension in this case is just plywood, cut to the width of the battery. Velcro is glued to the plywood (the other part is on the battery) and at the same time an additional adhesive tape is inserted to securely attach the battery.

Silicone tubes are attached to the suspension through the screeds, other silicone tubes are attached to the frame on the screeds, and then fastened together to dampen the vibration on the camera.

To prevent the copter from landing on the battery (which is extremely dangerous), 3 small rectangles can be cut out of PCB remnants and, by drilling holes in them, fasten them to the rays with ties.

With a relatively hard landing, the screeds fall off, quenching most of the fall energy, so the battery does not suffer (tested in a fall from 7 meters on the asphalt).

Crius Lite Flight Controller

Not so long ago, a very cheap flight controller with atmega328p and a set of sensors appeared on the site goodluckbuy: a gyro + accelerometer for the Lite version and an additional barometer and compass for the Standart version . I took the Lite version for two reasons: the price (at the time of purchase, the difference was 2 times) and the senselessness of other sensors (the course holds perfectly without a compass, and holding the height with jumps + -2 meters on the bmp085 sensor does not inspire me).

After the purchase, I recommend otkovyryat all unnecessary and rinse the handkerchief in alcohol, as almost all the Chinese have left a lot of conductive dirt that closes the contacts and can just kill the controller.

Fasten the board and related equipment (receiver) to the frame with foam tape . It holds very firmly, and at the same time it eliminates vibrations a little. (Only do not fasten the antenna so if you are going to fly far).

The weight of the copter is about 800 grams, the flight time with a 2.2Ah battery and camera up to 200 grams is about 10 minutes, while the power reserve is still about 40-50%.

The iron part ends and the game begins with the software.

Software

After the first connection of the board, it turned out that the flooded firmware is quite old, and with the sensor axes mixed up, i.e. You can even fly on this one. Therefore, download the Arduino IDE and the new firmware (do not download the dev!), And even better is the port from mahowik with a bunch of improvements.

Customization

Open through Arduino IDE sketch-firmware. The entire configuration is described in the config.h file (more details about most of the parameters and settings can be found here , in this article many trivia are omitted). For a tricopter we set the frame type #define TRI, the type of sensor board #define CRIUS_LITE and the filter for the gyro #define ITG3200_LPF_42HZ. And now in the Arduino IDE settings, select any 328p Arduinka and fill the resulting sketch.

Run MultiWiiConf for your system.

Since our rotary mechanism uses servo, which has properties to burn under heavy loads, it is better to find out and set limits for deviations of the serva. To do this, use the YAW stick on the control panel to reject the servo left and right and remember the maximum and minimum SERVO value in its extreme positions, and then enter these values in the config.h file

/* you can change the tricopter servo travel here */ #define TRI_YAW_CONSTRAINT_MIN 1340 #define TRI_YAW_CONSTRAINT_MAX 1855 And reload the sketch into the controller. Now you can try to take off, but note that the copter will rotate, so stream the YAW channel on the console so that there are no rotations during takeoff and flights, and then go back to MultiWiiConf, look at this value in the SERVO field and change it to

#define TRI_YAW_MIDDLE 1630 // tail servo center pos. - use this for initial trim; later trim midpoint via LCD ATTENTION! In the new firmware (2.0 and higher), similar trimming is done through the LCD screen or terminal, if you do not have either one or the other, you will have to change the code in Output.ino a little

#ifdef TRI motor[0] = PIDMIX( 0,+4/3, 0); //REAR motor[1] = PIDMIX(-1,-2/3, 0); //RIGHT motor[2] = PIDMIX(+1,-2/3, 0); //LEFT servo[5] = constrain(TRI_YAW_MIDDLE + YAW_DIRECTION * axisPID[YAW], TRI_YAW_CONSTRAINT_MIN, TRI_YAW_CONSTRAINT_MAX); //REAR #endif Ready configuration file for my trikopter nekaka.com/d/sgNj8AXp2Y - maybe someone will come in handy.

Now you can configure the PID , add camera grip control, etc. , as well as add GPS support with hold and return home functions.

Conclusion

In fact, the construction and configuration will be a lot of incomprehensible and interesting. But the occupation of aircraft modeling is demanding, and the occupation of copters is twofold, especially if you are a programmer and you want to improve the code of one of the open source projects.

And in the conclusion of the video of the recent flight, during which the kopter was badly damaged, but was quickly repaired right there on the field (thanks to the screeds and plastic bolts).

The shooting was carried out with 2x devices: a quadrocopter with a GoPro camera and my tricopter with an onboard FPV camera, the picture with which was recorded on the ground on an old miniDV camera.

ps: if you have any questions - ask, I will update the article as much as possible.

Source: https://habr.com/ru/post/144788/

All Articles