Battery that breathes

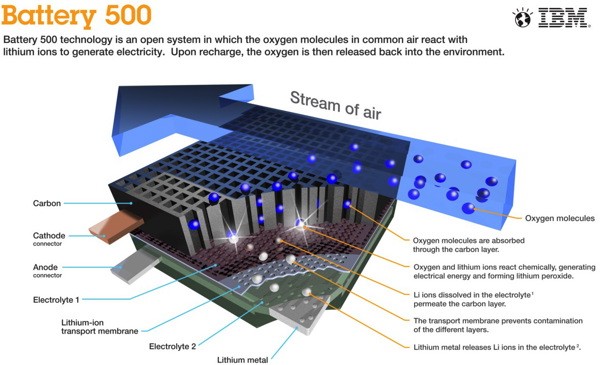

IBM continues to look to the future and work on projects that will make a revolutionary change in our lifestyle in the very near future. Such projects include " Battery 500 " - the project of a "breathing" battery, on which the average electric car can travel up to 500 miles (800 km) without recharging. In the blue giant, they were able to construct a battery that generates electricity by “breathing in” oxygen, and recharging - by “breathing out” it into the atmosphere. Thanks to this scheme (the exchange of air inside the battery), IBM researchers hope to reduce the size of batteries, their weight, as well as efficiency indicators - in comparison with ion batteries, Battery 500 promises to be much more economical and efficient.

Scientists have long looked at the side of lithium-air batteries, but so far only IBM has been able to build a working prototype. “The fundamental processes occurring in the battery are no longer questioned,” says Winfred Wilke, who is responsible for this direction (energy) in the company. IBM believes that with the help of this technology it is indeed possible to build a car rechargeable battery, on one charge of which it will be possible to make a trip up to 500 miles long. However, as Wickle notes, the prototype has a long way to go before actually entering the market: “We have a lot to do before we can install the battery in a real car.” But in the blue giant they expect that after 2020 the battery will be much more real than it is now, in the sense of mass production and use.

At present, the following situation has arisen in the automotive market: electric cars are still impractical, partly due to limited resource (cars produced today can travel an average of 200-400 kilometers without recharging), partly because of the bulkiness of the batteries themselves. The ratio of the weight of the battery to the amount of energy that it can provide to the engine is still not up to the same ratio in classical ICEs, where on one tank you can make a trip with a distance of more than a thousand kilometers (or even more). Improvements implemented in the technology of the production of batteries, today only slightly increase the amount of energy, but at the same time significantly weigh down the overall design.

')

It is easy enough to describe in simple terms what Wilke and his team were able to achieve: they deprived the battery of the internal oxygen exchange necessary for the normal course of reactions in the battery, instead relying on oxygen, which was well enough present in the atmosphere. Vital gas enters the “open system” cell in almost the same way as in the combustion chamber of a classical engine. Inside this cell, oxygen enters a very small space just over an angstrom (1.0 × 10 -10 meters), reacting there with lithium ions and electrons at the cathode of the battery. The ongoing reaction transforms lithium ions into lithium peroxide, releasing electrons and generating electricity for the engine.

“The main advantage is that we no longer need to try to compress the reaction,” says Wilke: “A battery can produce up to 10,000 milliamper hours per gram of cathode material used.”

At the same time, IBM immediately emphasizes that such a large increase in efficiency will not result in a proportional increase in power at the moment when the first electric cars with this type of battery inside the market appear - it still uses the materials necessary to support the reaction and at the same time, “eating up” part of the generated energy. But the experiment itself still shows how much more energy can be generated / stored using the technology used.

Once the battery is saturated with oxygen, it reaches its maximum charge and must be connected to a power source for recharging, during which the battery just “exhales” the accumulated oxygen, returning lithium to the ionized state.

The research team under Wilke, along with other teams of physicists from Zurich, used IBM Blue Gene to design a battery to simulate atomic processes, more specifically, to understand how the ions and molecules of the material from which the battery is made will interact and what processes will occur. .

In the near future, the team hopes to prepare a scientific article on the new technology, up to this point only some details will be available, most of which are described here. However, it can be immediately noted that recently discovered materials (such as graphene) are unlikely to be used in further experiments, and even more so in the production of lithium-air batteries - as Wilk says, everything related to carbon is not very suitable for creating fuel cells, as they become unstable with long use.

Introductory video in English:

Source: https://habr.com/ru/post/143792/

All Articles