Rebuilding Dual Opteron 252 server internals

I recently got a Tyan 2882-D motherboard with the words: “There were a couple of bloated capacitors, and it was also some kind of problem ...” The board included two AMD Opteron 252 and 6 GB memory processors. After replacing the capacitors, the board started up, but it was unstable. In BIOS, the temperature of one of the processors was 88 degrees. The second was 54 degrees. Also not wonders of coolness, but these Opterons differed by increased heat emission. Solution of the problem under habrakat.

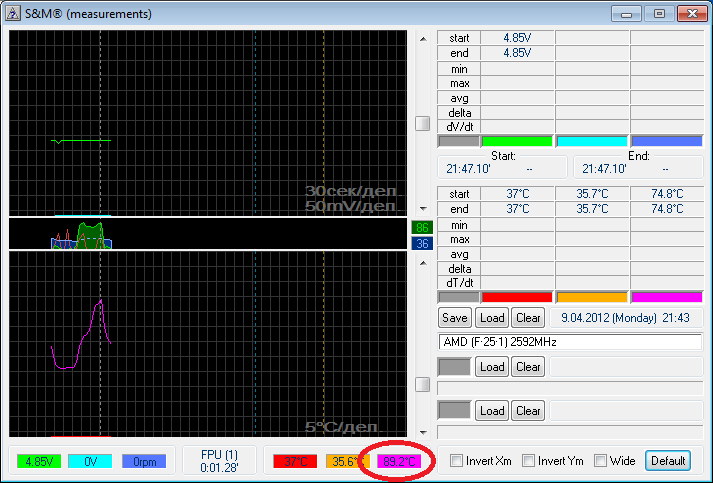

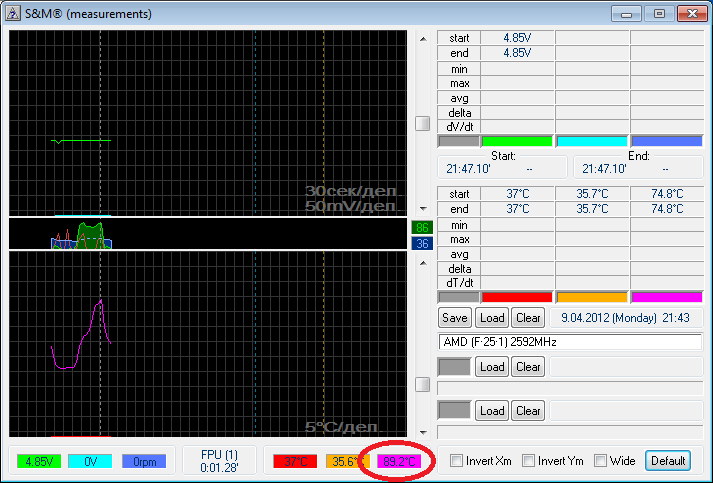

I decided to see what would happen next and after a couple of minutes the board safely disconnected. The radiators on the processors were barely warm. In order to make sure that the motherboard is working, I swapped the processors in some places. The overheating processor moved to the first socket and continued to overheat. I had to pull it out to configure the system on a non-overheating processor and see how it behaves under load. The result was already expected:

Reaching up to 90 degrees, S & M said that the thermal protection worked in the processor and interrupted the test.

Before that, I already assumed that the problem is the loss of the thermal interface between the crystal and the lid that closes it. It was decided to remove the cover from both processors and restore the heat sink. Out of curiosity, I searched the Internet for how much 252 Opterons now cost and was very surprised that they are still being sold. And the price of 15,000 rubles a piece seemed to me completely inadequate.

Attention! All further actions you can repeat at your own risk! If your not overclocked processor does not overheat in idle, do not remove the cover from it solely out of curiosity. On all modern Intel processors, the lid is soldered to the core and additional steps need to be taken to remove it. If you apply force, you will simply tear out the core and destroy the processor.

To remove the cover, we need a blade. Its thickness is less than the thickness of the gap filled with rubber, which holds the cover on the PCB. In order not to accidentally cut myself, I worked in cloth gloves. In order not to bend the legs of the processor, we insert it into the foam rubber. At first I tried to insert it into the foam, but it turned out to be too hard and then I had to straighten the bent legs of the processor. Insert the blade between the lid and textolite and gently deepen. Next, carefully hold the blade around the perimeter. The blade will be hard to slide in the rubber, so you need to apply force, but make sure that the blade does not bend or cut textolite. The blade can be deepened under the cover up to 5mm. If springy recoil disappears during movement and the blade gets stuck, then most likely it rested against mounted elements around the core. Carefully pull out the blade and continue cutting the gum.

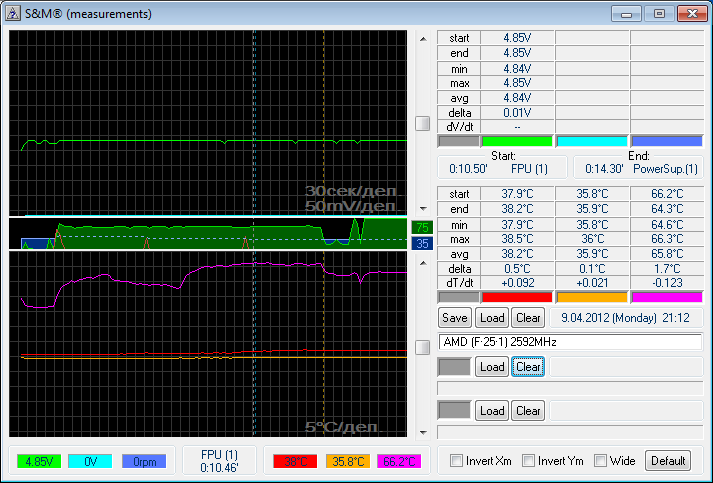

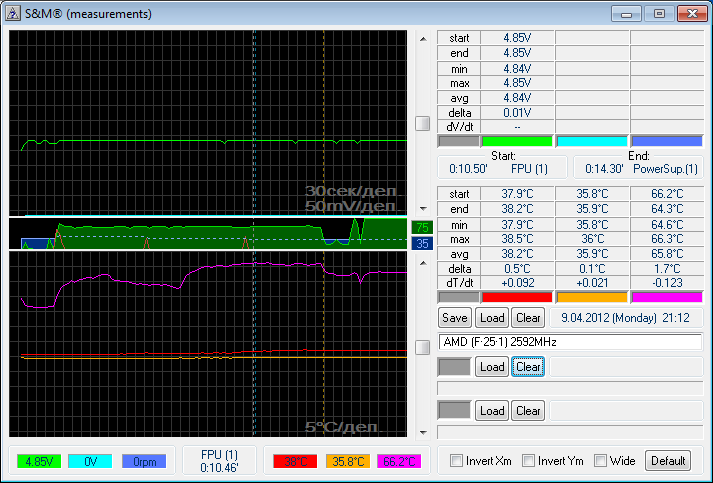

It is clearly seen that the manufacturer’s thermal grease has dried in the center of the crystal and has ceased to transfer heat to the lid. We clean the old paste, put a new one on the core, insert the processor into the socket, cover it with a lid, press it on top with a cooler, and check it. We start the processor test. The initial temperature is 55 degrees, but now with a load it does not exceed 67.

So we correctly identified the problem. Repeat the analysis and replacement of thermal paste for another processor. Now you need to collect everything.

We clean all residues of thermal paste from processors and coolers, apply thermal paste only on the cores. We degrease the textolite corners around the cores and the corners of the cover. Apply droplets of silicone sealant to the corners around the core. We cover and press, but not very much. Remove the excess seal, squeezed out from under the cover. We insert the processor into the socket and press it with a cooler. Thermal paste on the cooler now is not. We will apply it after the sealer dries. In the meantime, the cooler will work as a press. Leave for a day to harden the seal. We remove the coolers, apply thermal grease and assemble for final inspection.

In the test for maximum heating, the temperature was 66.5 degrees. The system is returned to work.

I did everything I described for the first time, so with careful work no problems should arise.

I decided to see what would happen next and after a couple of minutes the board safely disconnected. The radiators on the processors were barely warm. In order to make sure that the motherboard is working, I swapped the processors in some places. The overheating processor moved to the first socket and continued to overheat. I had to pull it out to configure the system on a non-overheating processor and see how it behaves under load. The result was already expected:

Reaching up to 90 degrees, S & M said that the thermal protection worked in the processor and interrupted the test.

Before that, I already assumed that the problem is the loss of the thermal interface between the crystal and the lid that closes it. It was decided to remove the cover from both processors and restore the heat sink. Out of curiosity, I searched the Internet for how much 252 Opterons now cost and was very surprised that they are still being sold. And the price of 15,000 rubles a piece seemed to me completely inadequate.

Attention! All further actions you can repeat at your own risk! If your not overclocked processor does not overheat in idle, do not remove the cover from it solely out of curiosity. On all modern Intel processors, the lid is soldered to the core and additional steps need to be taken to remove it. If you apply force, you will simply tear out the core and destroy the processor.

To remove the cover, we need a blade. Its thickness is less than the thickness of the gap filled with rubber, which holds the cover on the PCB. In order not to accidentally cut myself, I worked in cloth gloves. In order not to bend the legs of the processor, we insert it into the foam rubber. At first I tried to insert it into the foam, but it turned out to be too hard and then I had to straighten the bent legs of the processor. Insert the blade between the lid and textolite and gently deepen. Next, carefully hold the blade around the perimeter. The blade will be hard to slide in the rubber, so you need to apply force, but make sure that the blade does not bend or cut textolite. The blade can be deepened under the cover up to 5mm. If springy recoil disappears during movement and the blade gets stuck, then most likely it rested against mounted elements around the core. Carefully pull out the blade and continue cutting the gum.

It is clearly seen that the manufacturer’s thermal grease has dried in the center of the crystal and has ceased to transfer heat to the lid. We clean the old paste, put a new one on the core, insert the processor into the socket, cover it with a lid, press it on top with a cooler, and check it. We start the processor test. The initial temperature is 55 degrees, but now with a load it does not exceed 67.

So we correctly identified the problem. Repeat the analysis and replacement of thermal paste for another processor. Now you need to collect everything.

We clean all residues of thermal paste from processors and coolers, apply thermal paste only on the cores. We degrease the textolite corners around the cores and the corners of the cover. Apply droplets of silicone sealant to the corners around the core. We cover and press, but not very much. Remove the excess seal, squeezed out from under the cover. We insert the processor into the socket and press it with a cooler. Thermal paste on the cooler now is not. We will apply it after the sealer dries. In the meantime, the cooler will work as a press. Leave for a day to harden the seal. We remove the coolers, apply thermal grease and assemble for final inspection.

In the test for maximum heating, the temperature was 66.5 degrees. The system is returned to work.

I did everything I described for the first time, so with careful work no problems should arise.

')

Source: https://habr.com/ru/post/141776/

All Articles