Trikopter (DIY Quadcopter: Part II.2)

Of course, I remember that I promised to write the third part about flying on GPS and other buns, but it so happened that I spent all summer with my son, soldering iron and Arduino IDE, and not in the field with a copter, so now my free translation of the article by Swede David Windestol (David Windestål , I hope I wrote correctly) about the construction of a tricopter - pepelats with three motors and a turning mechanism for compensating rotation and controlling the rotation. (a big request not to go without special need to the original site, as it often falls even without a habr, and there are a lot of pictures under the cut)

Of course, I remember that I promised to write the third part about flying on GPS and other buns, but it so happened that I spent all summer with my son, soldering iron and Arduino IDE, and not in the field with a copter, so now my free translation of the article by Swede David Windestol (David Windestål , I hope I wrote correctly) about the construction of a tricopter - pepelats with three motors and a turning mechanism for compensating rotation and controlling the rotation. (a big request not to go without special need to the original site, as it often falls even without a habr, and there are a lot of pictures under the cut)Since the first version of the tricopter was built, I tried to find ways to improve the design: I constantly changed the propellers, motors, speed controllers, the length of the rays, the turning mechanism, etc. Often, I changed a lot of everything before each flight. In general, constantly trying to find the best option for themselves.

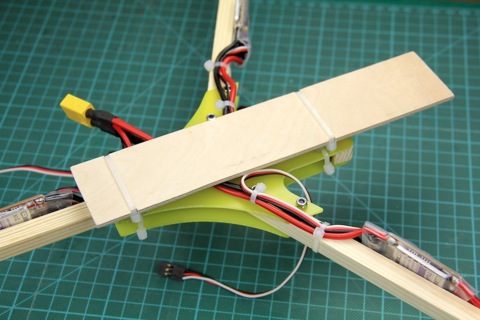

I adore screeds. They make the construction process easy and quick. They break down when they fall, taking energy over themselves and are the key to a more durable tricopter. Instead of changing the axis of the motors, which is bent - it is easier to replace the detached screed. And most importantly - it is very easy to do in the field.

Main details

(Note: you can use any other similar parts)

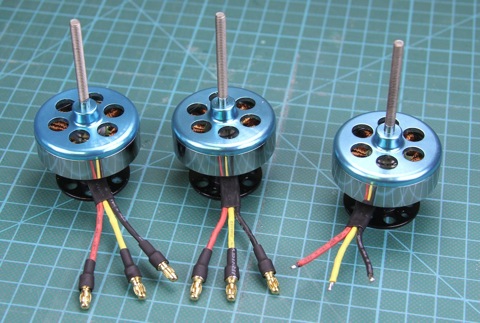

Motors: DT750 750kV

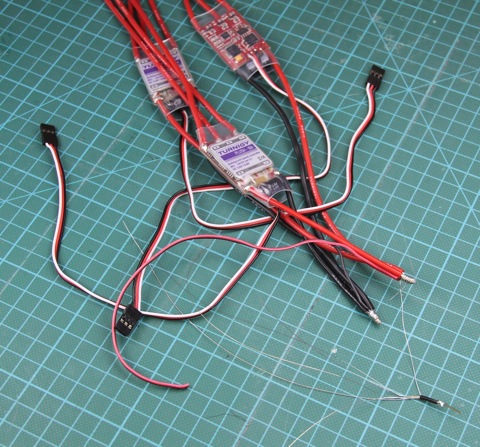

Speed Controllers: TURNIGY Plush 18amp

Battery: 3s Turnigy 25-35C 2200mAh LiPo

Serva: BMS-385DMAX Digital Servo Metal Gear

Propellers: GWS 10 * 4.7 or GWS 11 * 4.7 if you need to lift something heavier

Length is better: about 50 cm (from the center to the axis of the motor)

Take-off weight: 860 grams (including a battery or 670 grams without it)

Flight time: about 12 minutes

Current in hover: about 10 Amps

Test of motors: 13.2A@11.7V - 7770RPM - 1080 grams per motor (thrust)

')

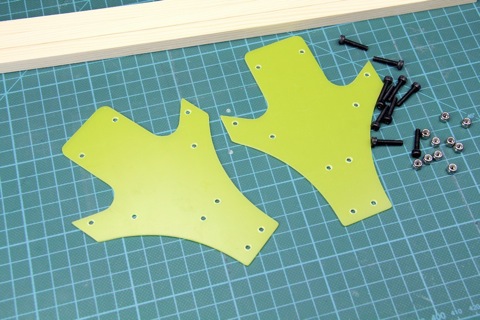

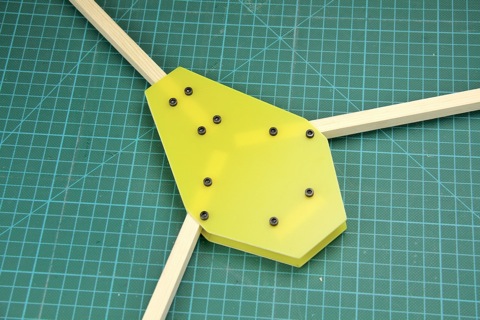

Frame details

I still like the central part of the first version tricopter and my friend happily chopped some for me on a CNC machine.

It will take 10 pieces of M3x16 mm bolts.

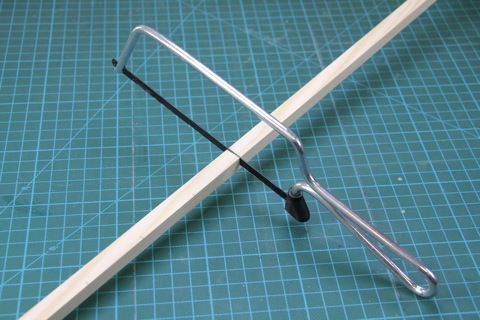

And three beams of the same length. I cut 48cm rays 10x10 mm from pine.

Holes in the front rays are drilled 25mm from the edge. This is more than planned for the workpiece, but the additional material adds strength to the whole frame, like a small piece of wood in front of a long 40mm.

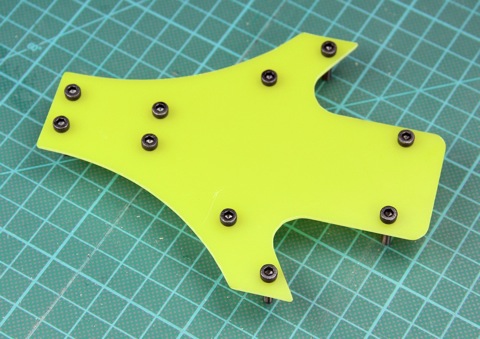

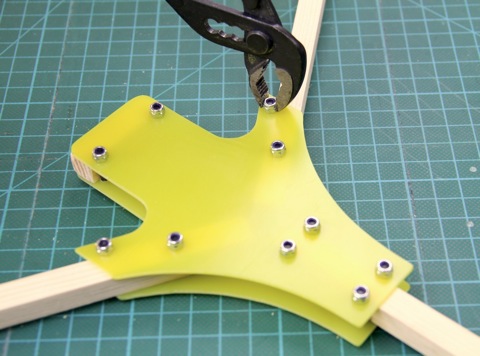

It is time to twist it all M3 nuts with fixation. Arrange the rays before tightening the nuts. Rays must be in contact with the bolts in the unfolded state. Be careful not to overtighten the nuts, but they must be tightened so that the rays hold up during the flight. Well, the main part of the frame is ready.

You can also use a simpler central part. At the same time it is useful if you have to hang a lot of equipment. Just circle the main drawing in the corners and it will be easier to cut if there is no CNC machine, as all lines are straight.

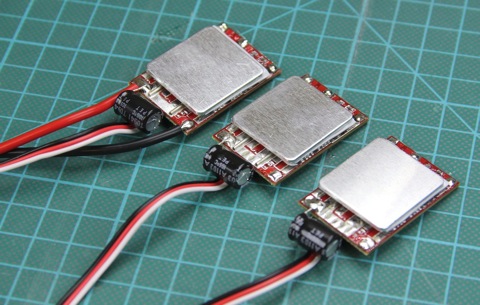

Speed controllers

Time to "fix" the speed controllers. Remove heat shrink from them (be careful, do not damage the insides).

Remove all wires (except for 3-wire) from the two speed controllers, and leave the power wires on the third one. This third regula will be on the tail and it just so happens that the length is just enough. (Note: check if you have enough length with other speed controllers).

Use a 16AWG cable to extend the wires. I also recommend soldering the connectors for the motor. And use heat shrink to protect the regulator from dust and dirt.

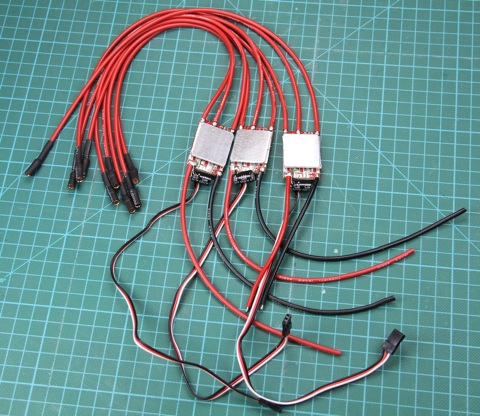

It's time to solder all the power wires together. In order not to suffer when soldering - wind the wires with wire, this will help keep them together.

Solder the power connector and ready.

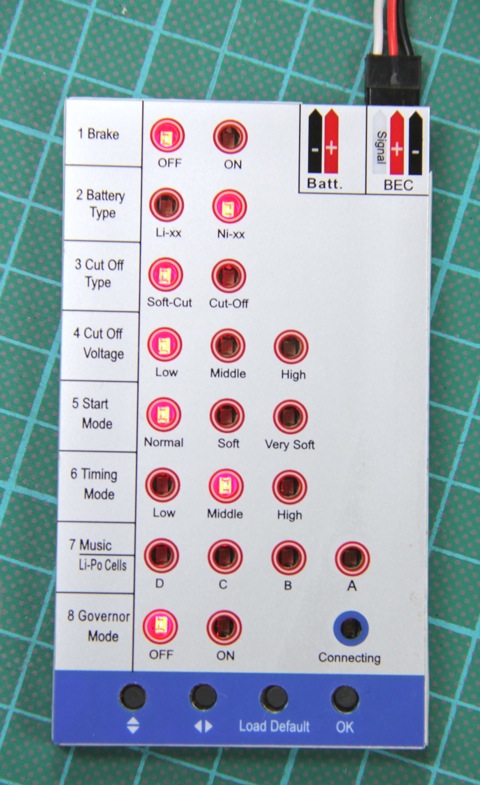

We program speed controllers. I used the card for programming and these settings are suitable for my speed controllers. (Note: it is not necessary to use the card for programming controllers, you can use the directions in your instructions for regulators).

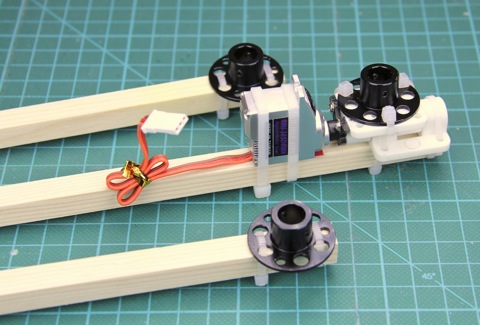

Swivel mechanism

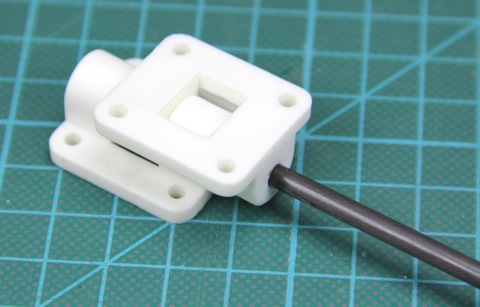

The time has come for the rear motor turning mechanism. Here is a bag with 40mm mounts for the front wheels. Only $ 2.5 for two and a half turn nodes.

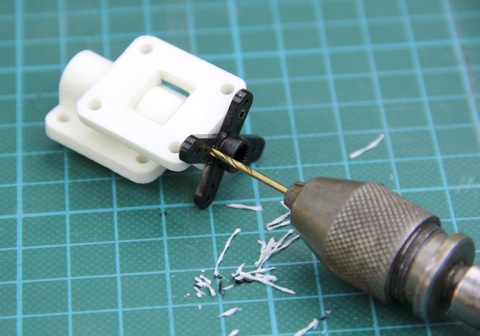

Take two such things and drill a 4.2mm hole in one of them.

Remove all debris after drilling and insert a 4mm axis (note: for example, a carbon tube from a fishing rod) . It clearly fixes in the part that is not drilled. We'll have to try to insert one into the other.

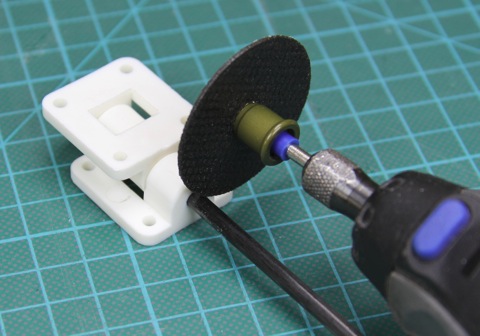

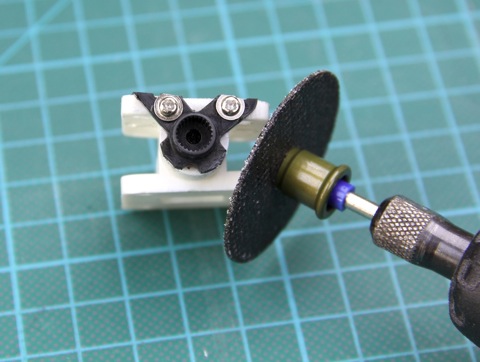

Saw off too much. I used a dremel with a disk.

We grind irregularities on the part that was drilled.

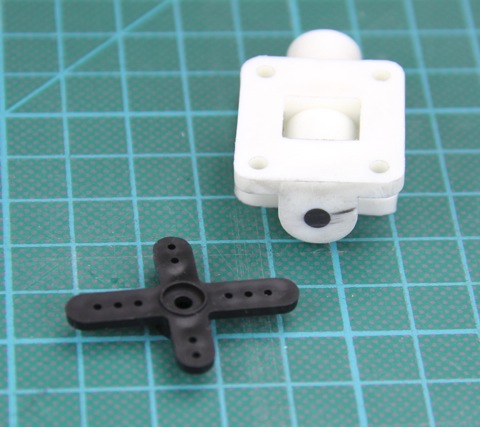

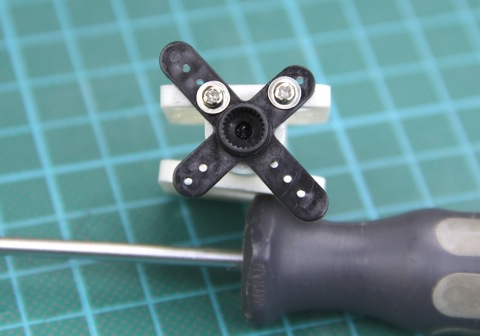

The time has come to connect the turning mechanism with the servo. Used serv came with a cross mount, which is perfect for us.

Make the crossbar flat.

And glue to the swivel mechanism, so that later it would be easier to drill, and it will be stronger. A couple of important things: we glue the spider on the part that was not drilled and we are trying to make its hole coincide with the shaft installation site. If it fails, there will be an extra load on the serv.

Now let's drill two 1.2mm holes. Drill a little deeper than the length of the screws, which then you will fasten it.

And fix the screws, for example from a small serva.

Cut off the excess.

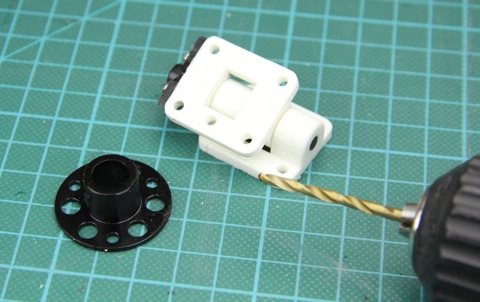

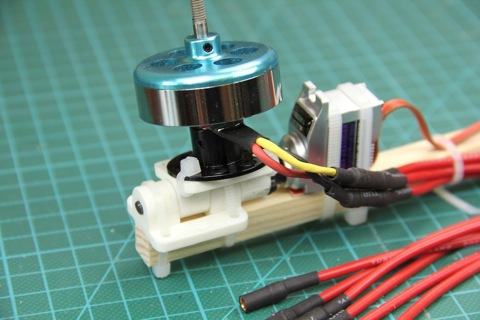

Mounts DT750 is very well suited for such a mechanism. Only it is necessary to drill one hole in the turning mechanism, where the motor will be strengthened (and where the crosspiece from the servo is screwed).

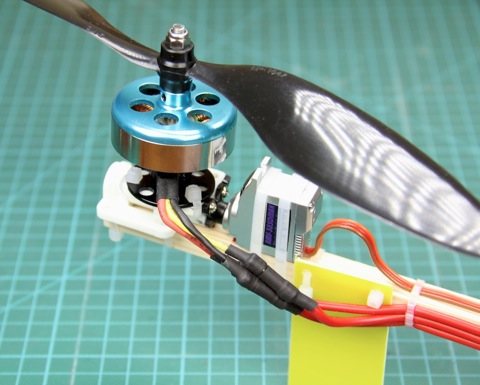

Three 2.5mm ties all that is needed to secure the motor. It is better to fasten the ties as shown in the picture, so as not to interfere with the deviation of the turning mechanism.

And now we will remake a little a servu, having cut off the bottom part of the mount. In order for the server to fit in height, you will have to add 0.8mm fiberglass or grind off a pivoting mechanism at these 0.8mm.

Swivel gear ready. It remains only to fasten the buckles to the rear beam.

Servu attract thicker ties. When installing screeds, make the screed locks on different sides of the beam.

Motors and assembly

Let's start soldering the connectors to the DT750 motors. I adore DTshki. They are quite effective, have high torque. This means that the propellers will be able to change the rotational speed faster and the tricopter will be more stable and have a good response. I also like the 4mm threaded shaft, on which you can install propellers without any extra mounts.

But the weak point of these engines at the junction of the wires with the winding. If you move the wires back and forth, then most likely they will just fall off. To fix this and make the engines more durable - we fix this place with epoxy.

The motor axis protrudes slightly from the motor mount, so I made a small indentation in the beam to prevent friction. The friction of the motor on the beam will cause unnecessary vibrations, so the easiest and fastest way is to drill a small recess.

Attach the 2.5mm motor coupler to the beam. Simple, cheap and fast. And it will save the motor during a collision with the ground / asphalt, etc.

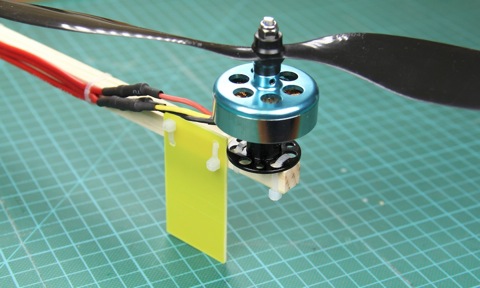

The axes of the motors are too long, which adds the risk of damaging the motor when dropped (and the vibration is stronger). I cut off the excess, leaving about 21mm, that's enough for a GWS propeller and a bolt.

And now we put the engines in place. Always use something to fasten the bolts, otherwise they will spin up due to vibrations in flight.

Install the rear motor so that the wires are perpendicular to the beam, then they will not cling and rub against the serv.

The landing gears are fastened with fasteners and the propeller is mounted on the motor. The propeller will have to squander up to 4mm. Use special bolts to prevent the propeller from falling off.

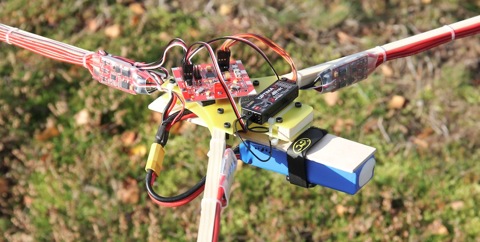

We install speed controllers, as well as an extension for the servo.

This tail turning mechanism has low friction and is quite durable. The server is installed vertically in order not to interfere with the air flow from the screw. I like the direct servo drive when there are no flimsy and unnecessary parts.

Depreciation of the camera and flight controller

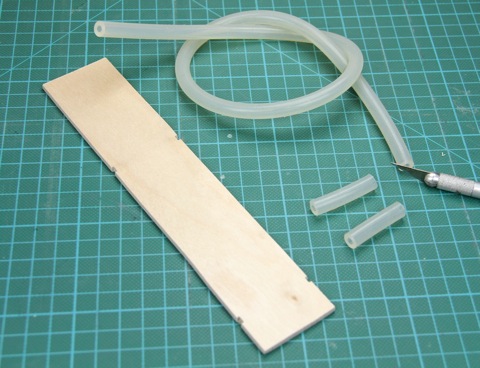

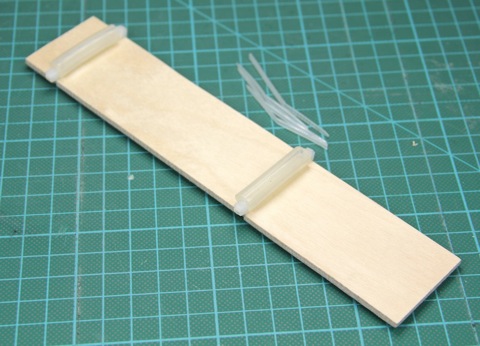

It's time to talk about mounting the battery and the camera (note: I will call it a suspension later) . To prevent vibrations, I used 2 pieces of 38mm silicone tube (note: a fuel hose or a tube for the pet shop aquarium). 8mm outer diameter and 3mm inner.

I used a 2.5mm tie (suddenly!) To fix the tubes on the gimbal.

The suspension is attached to the bottom with the same 2.5mm ties.

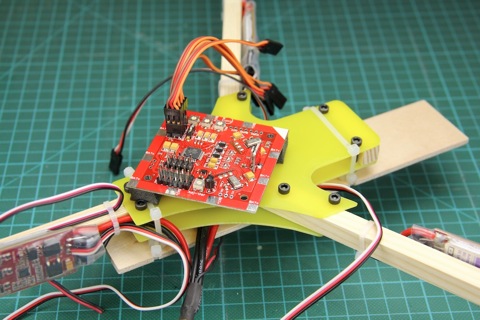

I still like the CaptainCook (KK) controller, you can buy it anywhere (note: and even better, buy, for example, MultiWii or another flight controller with automatic alignment to the horizon) .

To secure the flight controller, I used squares of several layers of thick scotch. Just stick them on it and on the frame.

Add a battery and ready to fly.

Frame assembled. Pretty convenient for transportation.

I hope I liked the translation, in fact, the translator from me is so-so - at school and the university I barely passed tests / exams

Some videos of flights on this tricopter

and much more on the author's channel on youtube .

Where to find the details?

Most of the details can be purchased on the site hobbyking.com , as well as saving money by using this site with buddy codes for discounts.

And on goodluckbuy.com there is a whole section for multikopter , in particular, there you can find quite cheap flight controllers (and even full copters), but you should keep in mind that not all controllers support a tricopter frame.

Full parts list and replacements are possible.

What is meant by the replacement - personally put on your tricopter.

| Name | Min number | Used in the article | Alternative |

|---|---|---|---|

| Motor | 3 | DT750 750kv - $ 11.60 | KDA20-22L - $ 14.72 |

| Speed controllers | 3 | TURNIGY Plush 18amp - $ 11.90 | HobbyKing 30A BlueSeries - $ 10.47 (actually 30A is a brute force) |

| Serva | one | BMS-385DMAX - $ 20.48 | BMS-621MG - $ 23.80 (very large, I do not recommend) |

| Propellers | 3 | GWS 1047 - $ 4.82 or GWS 1147 - $ 5.76 | 10x6 - $ 3.48 or 11x4.7 - $ 5.98 |

| Batteries | one | 3s Turnigy 25-35C 2200mAh LiPo - $ 8.99 | Turnigy nano-tech 2200mah 3S 25 ~ 50C Lipo - $ 17.99 |

| Flight controller | one | HobbyKing Multi-Rotor Control Board V2.1 (Atmega168PA) - $ 14.99 | Crius MultiWii Lite - $ 47.52 (actually analogous, but sensors separately, Arduino separately) |

| Swivel Parts | one | Front Wheel Steering Arm & Mount Set 40mm (5sets) - $ 2.59 | |

| Rest | There is a lot more to be needed, for example bolts, nuts, wires, glass fiber laminate for a frame, aluminum beams, or wood, but all this can be found in nearby stores or on the same hobbyking.com | ||

| TOTAL | $ 122.37 - $ 123.31 | $ 170.95 - $ 173.45 | |

To this price you need to add shipping costs, as well as take away the discount, which can be obtained here .

Of course, the tricopter will also need control equipment and a battery for it.

Source: https://habr.com/ru/post/141669/

All Articles