Plotter from the designer FISCHERTECHNIK

I have long had an idea to build something from the field of CNC machines. But there were constantly obstacles to the realization of my creative impulses: either there is no time, then there is a problem with the tool or the details for the mechanisms. And when I got the hands of the children's designer FISCHERTECHNIK, I understood - that's it!

So, we are building a programmable plotter.

Any plotter has a carriage that can move along the X and Y axes. A tool is attached to this carriage. It can be a pen or a cutting knife. The tool is clamped to the material by a separate drive, which in our case will work as the Z axis.

')

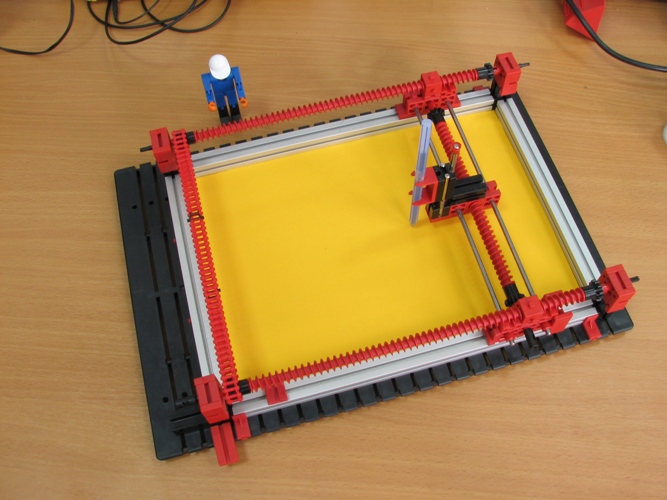

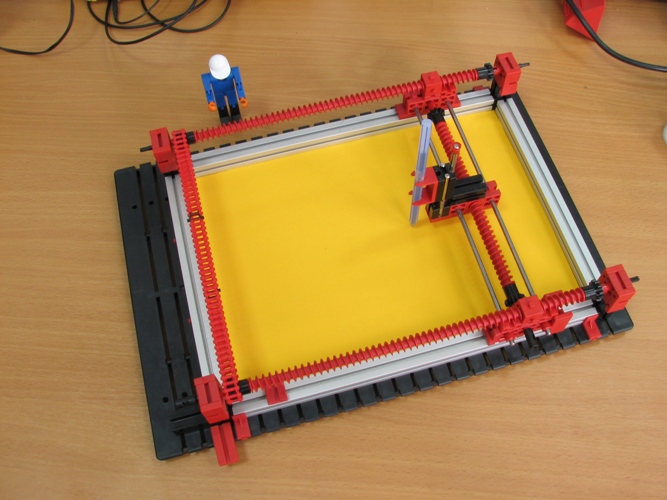

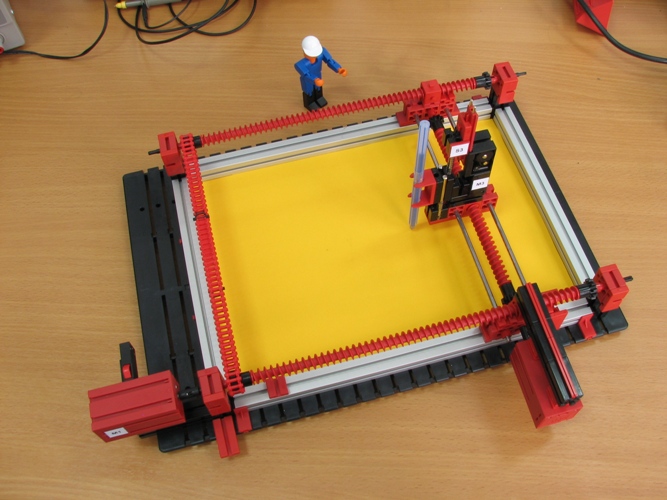

01. Construction. As the base we use a plastic plate. The frame combined with guides for the X axis is made of aluminum profile, which is also in the fischertechnik parts list.

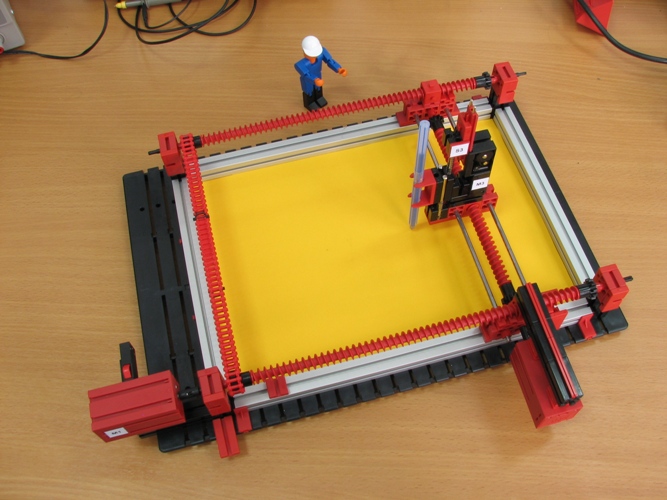

02. Servomotor. To move the carriage along the X and Y axes, we use screw pairs and servo motors with encoders. The resolution of encoders 75 imp / rev and screw pitch of 5 mm results in a linear resolution of the positioning system of 15 imp / mm. That is enough for my amateur task.

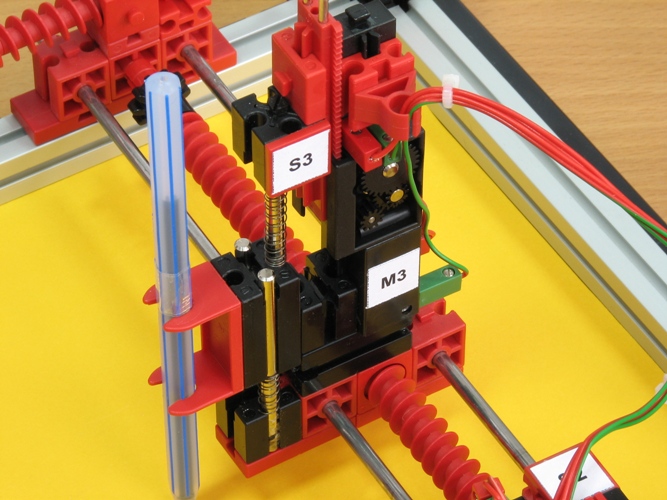

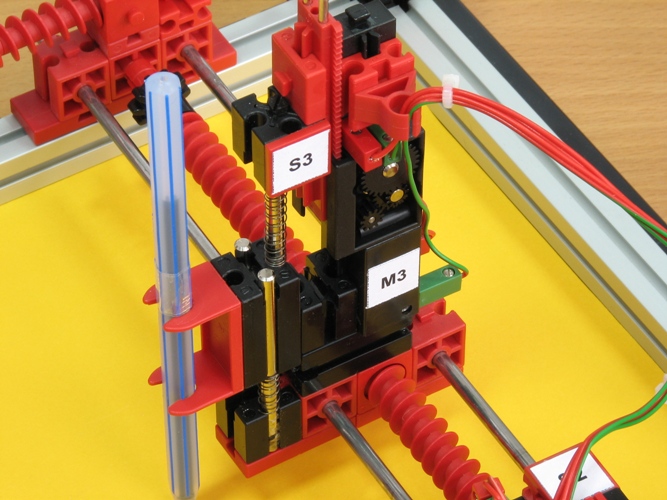

03. Z axis. The tool feed to the web (Z axis) will perform the mechanism with a rack. It does not have encoders, so the limit switch and the delay for switching off the drive by timer are used to control the position.

04. Mechanism assembly.

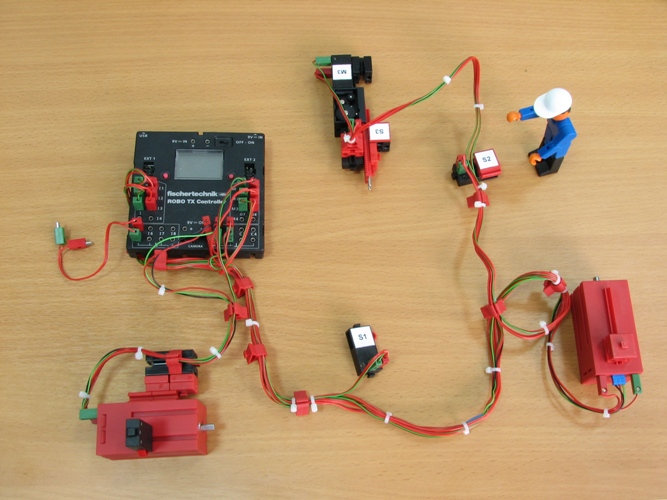

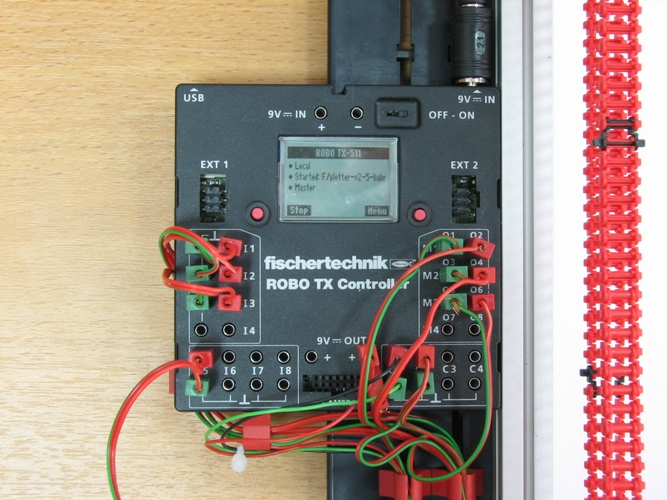

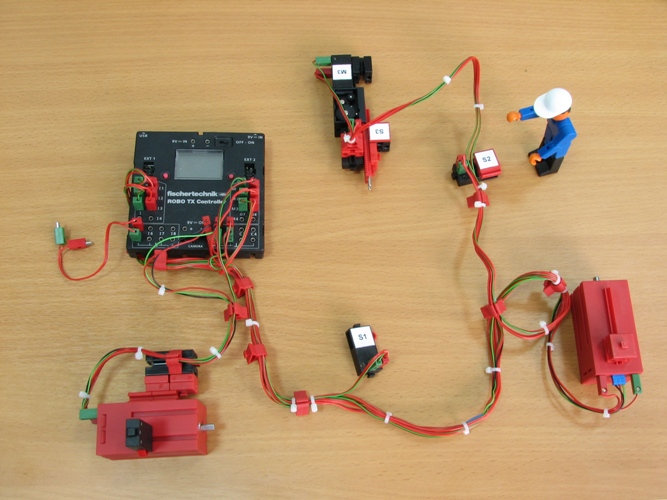

05. Electrical wiring. Now it's electrical installation. Wiring is done using plugs with screw clips.

06. The mechanism is assembled, the wires are connected.

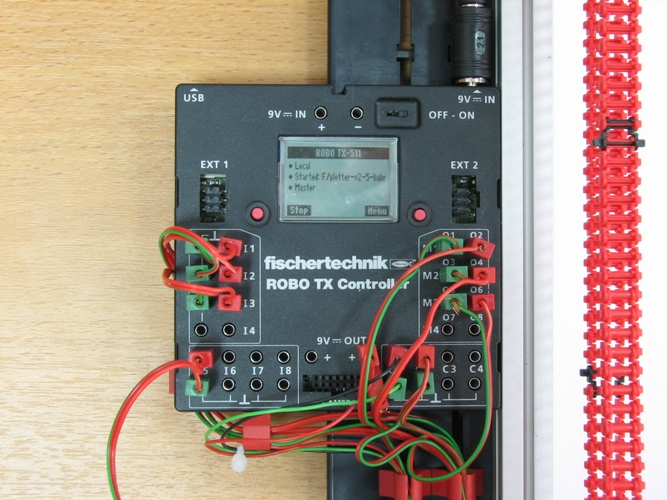

07. Now it's up to the control system. Last time I used Arduino for control. This time the brain will be the ROBO TX controller from the fischertechnik designer.

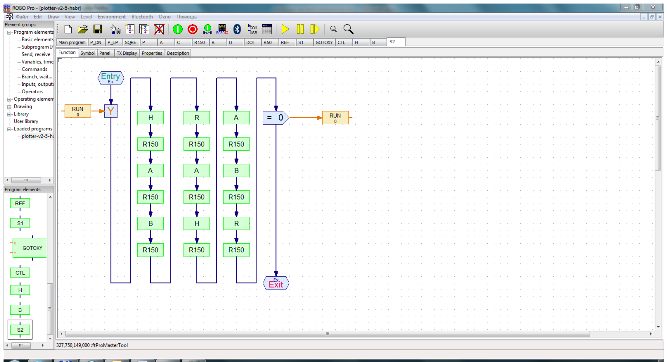

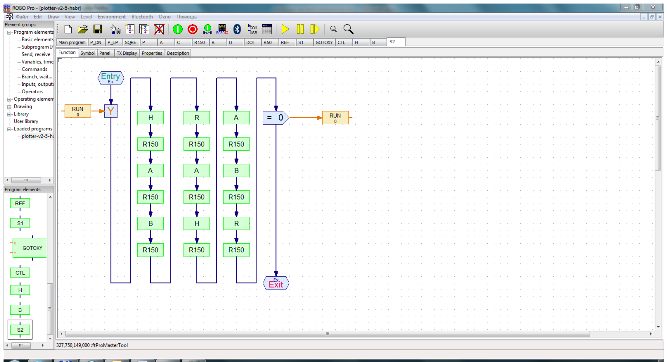

08. The program for the ROBO TX controller is compiled in a visual programming language in the form of an algorithm. Moreover, this language is very similar to the flowcharts that are found in textbooks on computer science, and the corresponding GOST 1 . I believe that this feature of the software will be very useful for students who learn the basics of programming.

I have compiled a simple program for outputting one line - “HABRAHABR”. For each character created a separate subroutine. Total got 4 subroutines.

Here you can see what I did.

Now I have a desire to implement a G-code interpreter for a ROBO TX controller. Then it will be possible to transfer the files from the CAD systems to the G-code and get a full-fledged, from a functional point of view, CNC machine layout.

1 - GOST 19.701-90 Schemes of algorithms, programs, data and systems. Conventions and execution rules.

The fischertechnik designer for the article is kindly provided by the PAKPACK store.

So, we are building a programmable plotter.

Any plotter has a carriage that can move along the X and Y axes. A tool is attached to this carriage. It can be a pen or a cutting knife. The tool is clamped to the material by a separate drive, which in our case will work as the Z axis.

')

01. Construction. As the base we use a plastic plate. The frame combined with guides for the X axis is made of aluminum profile, which is also in the fischertechnik parts list.

02. Servomotor. To move the carriage along the X and Y axes, we use screw pairs and servo motors with encoders. The resolution of encoders 75 imp / rev and screw pitch of 5 mm results in a linear resolution of the positioning system of 15 imp / mm. That is enough for my amateur task.

03. Z axis. The tool feed to the web (Z axis) will perform the mechanism with a rack. It does not have encoders, so the limit switch and the delay for switching off the drive by timer are used to control the position.

04. Mechanism assembly.

05. Electrical wiring. Now it's electrical installation. Wiring is done using plugs with screw clips.

06. The mechanism is assembled, the wires are connected.

07. Now it's up to the control system. Last time I used Arduino for control. This time the brain will be the ROBO TX controller from the fischertechnik designer.

08. The program for the ROBO TX controller is compiled in a visual programming language in the form of an algorithm. Moreover, this language is very similar to the flowcharts that are found in textbooks on computer science, and the corresponding GOST 1 . I believe that this feature of the software will be very useful for students who learn the basics of programming.

I have compiled a simple program for outputting one line - “HABRAHABR”. For each character created a separate subroutine. Total got 4 subroutines.

Here you can see what I did.

Now I have a desire to implement a G-code interpreter for a ROBO TX controller. Then it will be possible to transfer the files from the CAD systems to the G-code and get a full-fledged, from a functional point of view, CNC machine layout.

1 - GOST 19.701-90 Schemes of algorithms, programs, data and systems. Conventions and execution rules.

The fischertechnik designer for the article is kindly provided by the PAKPACK store.

Source: https://habr.com/ru/post/140241/

All Articles