How to cook HDD

(You do not like Seagate? You just do not know how to cook them!)

For NAS, I had to buy HDD 3TB WD Caviar Green IntelliPower (there were simply no other treshkas). Hands habitually took the "file" and began to "chamfer", from the eyes of the tears of resentment - seven and a half thousand for IT. Yes, "guarantee", yes, RAID5, but keep in mind the next 6-8 months rebuild of terabyte arrays ?! And then the news about the reduction of warranty periods by vendors. No, I understand very well why they reduce the guarantee - IT should not work at all. But why not improve the quality of products? However, I understand that, it’s necessary to sell a lot and not work for a long time. And then here are my three 2TB Barracudas for the second year under the 7/24 torrent are working and not beating, and Seagate is starving.

And so, if you are warming the garthalon - this topic will not be interesting for you. If you have a Seagate 7200 Constellation ES RAID6 - your time is too expensive to read such trifles. If you have spent your hard-earned money and you want "that it would not be painfully painful" - look under the cat, you can find something useful.

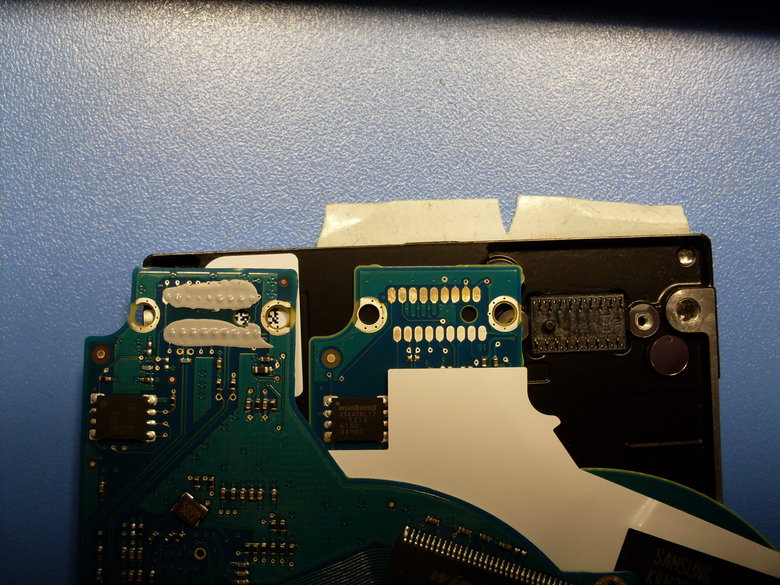

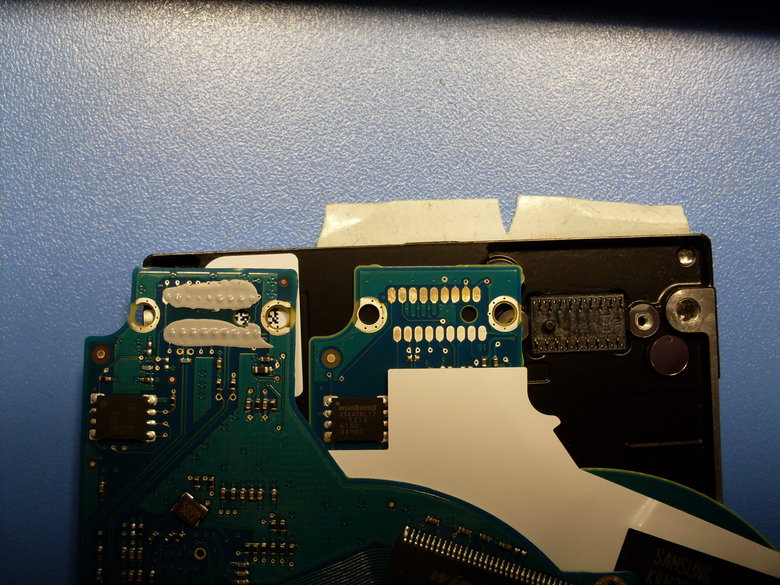

Long ago, when the trees were large, cold contacts were made to gild. Then gold found another use - they began to save it, and contacts, respectively, were tinned. We look, we see, we think (contacts of the block of heads).

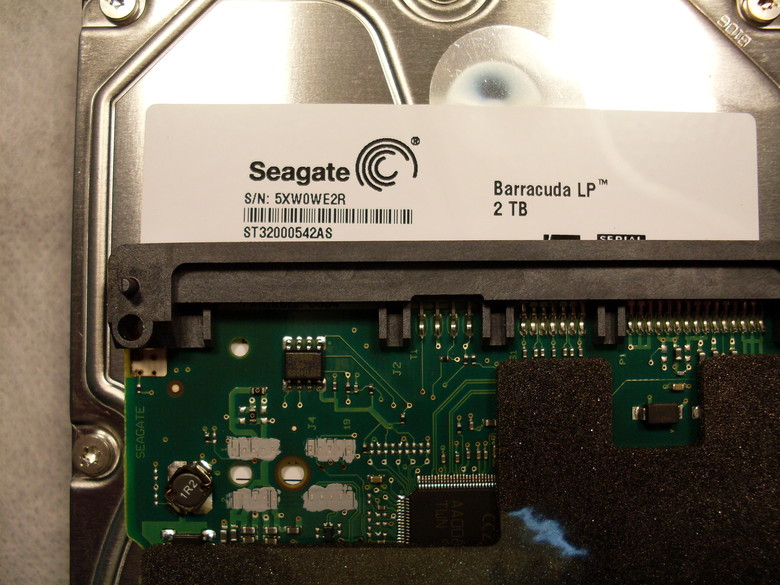

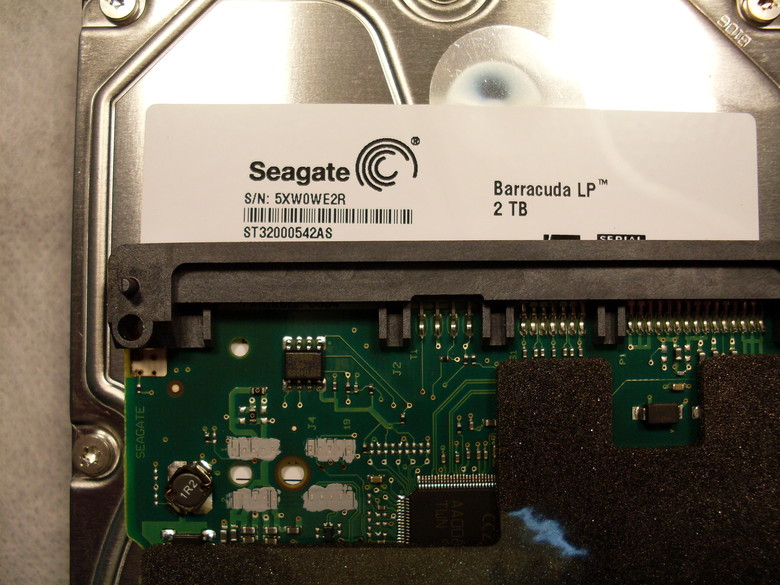

The disc worked for an ordinary user in a beech for about 5 months and died quietly, taking all the memories of the owner with him to his grave. Whether the head preamplifier died from unstable power supply, or the controller overheated from the constant miscalculation of the CRC-Error, the warranty service is all the same - replacement. Without the possibility of data recovery or compensation for their loss. Following! The new disk looks exactly like the old one five months ago. So, this one will last to the end of the guarantee and a little more, if you're lucky. Lucky not all. View of new disk controllers that came under warranty replacement in sealed silica gel bags.

')

And this is not cheap 320s, but tops in its segment.

Calm and data integrity is more important to me.

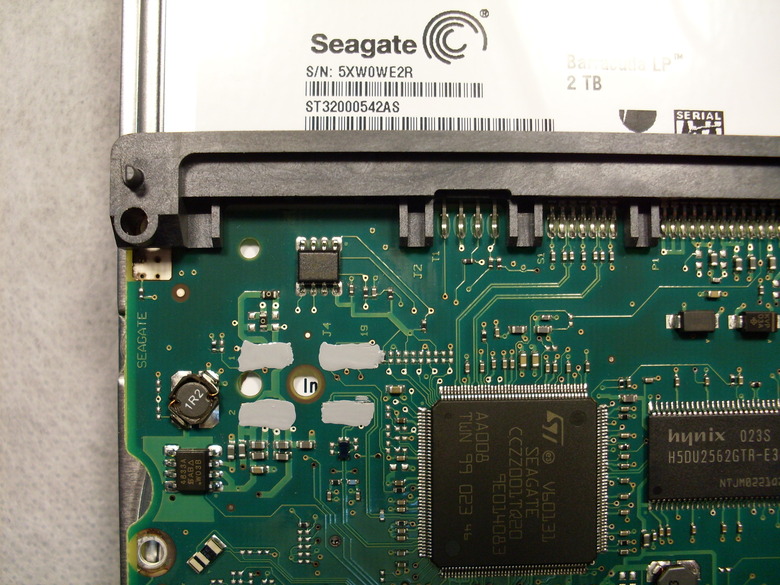

I believe that the meaning is clear. Conventional silicone-based thermal grease is applied to well-degreased contacts. Thermal grease has two properties I need, it does not dry out and is non-conductive. I used to use KPT-8, but Zalman ZM-STG1 has a comfortable brush, like in nail polish. Back controller board is put "in one motion" - aim and vertically lower on the bank. It is necessary to avoid the displacement of contacts on the paste, so that there would be no exposed areas. If you got a product with already oxidized contacts, rub them with a soft scrub brush and brush away the crumbs, wipe with alcohol or gasoline for lighters.

After a year of operation, 2TB were enumerated.

Under Zalman-ovsky thermal grease were brilliant sites.

In a new way ...

This method has been used for more than five years. The mentioned 3TB has been modified in the same way. I hope to sell it in a couple of years, together with partners on RAID, when it becomes crowded.

Ideally, I want to find a method of “gilding” contacts at home.

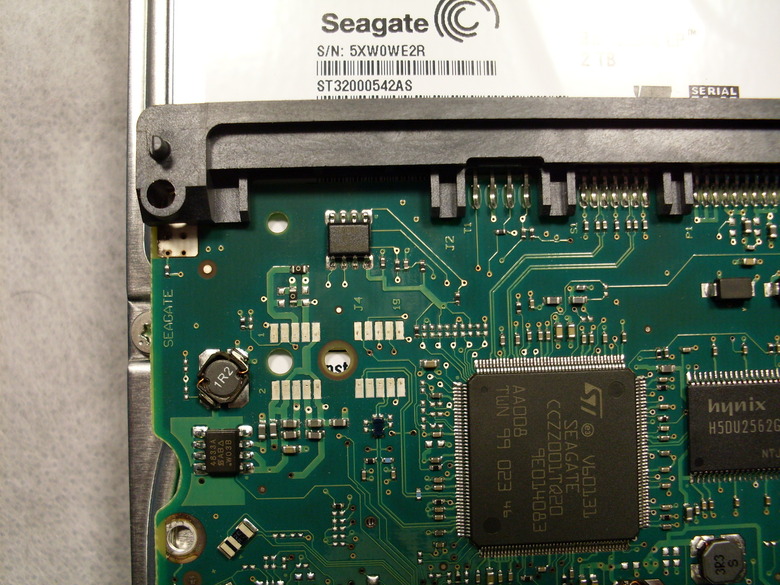

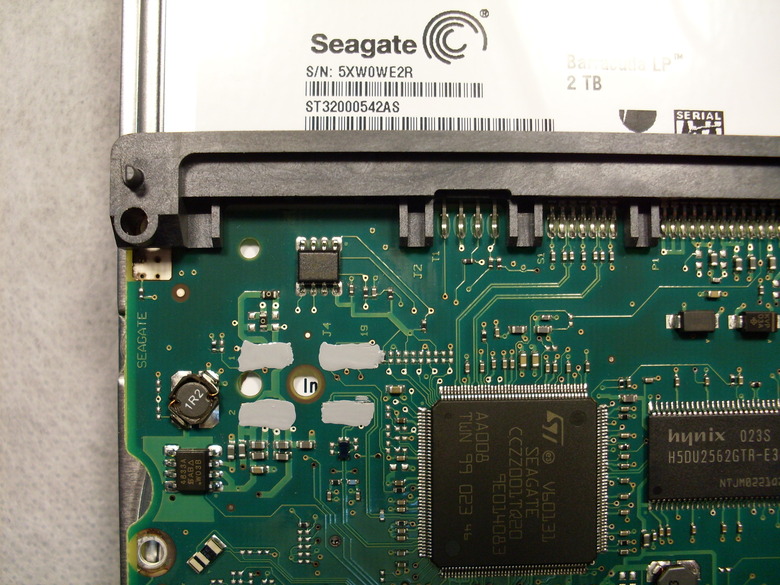

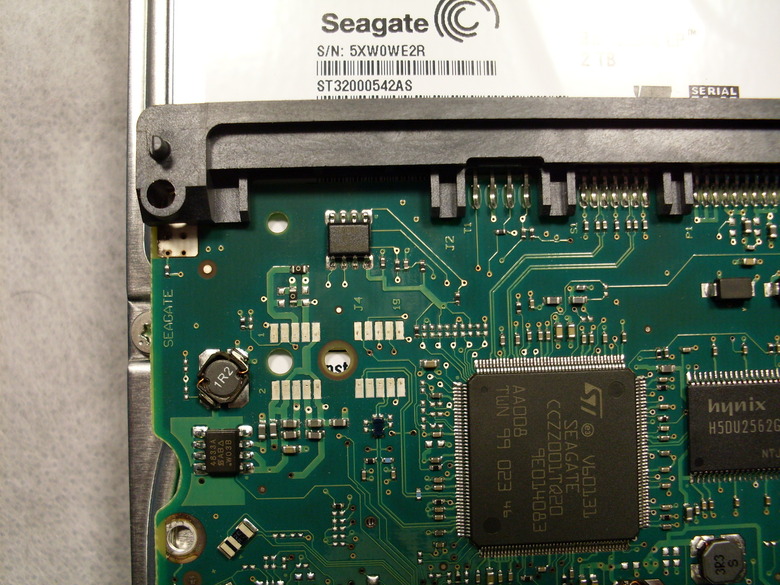

The second “file completion” is prompted by the railway manufacturer itself and a hand-type gauge. When performing a large number of disk operations on an easily accessible hard disk drive, for example, connected to a USB-SATA adapter, the heating of the hard disk controller board in two places is well felt. On the inside there are located - the controller and the driver of rotational and linear motors. Between the can of railway and the controller board is laid cellophane with glued foam. A thermal strip is applied over the driver chip instead of foam rubber, and a pad is milled on the jar.

The gasket is of good quality and well adhered to the chip, but the thermal conductivity of cellophane between the gasket and the metal is a big question.

I completely remove the foam pad. The gap between the driver chip and the platform on the HDA is approximately 1 mm. I use white or blue thermal pads 1.5mm - they are elastic enough to squeeze out the excess from the place of contact. The gasket is superimposed on the chip, the board is baited with screws and it bends over the gasket. We press the board over the thermal pad before alignment and tighten the screws.

I have no experimental data on the benefits of these improvements. However, when I caught the word “fly tse-tse” and having considered the situation in general, I modified for personal consumption a dozen and a half railway and did not lose a single one in a few years. Of the several dozen modified railway that went to the side of good people, one returned. However, the over-the-counter G-sensor made it quite natural for badblocks to appear.

Good luck to all and non-surviving hard drives.

ps The original version of this post was kept for a long time in the draft, because could not be published due to a lack of you-know-what, and as a result appeared on a third-party resource. Here is published a revised and updated version of the material.

upd. This addition is for those who follow the topic, so as not to breed holivar. Once upon a time there were special utilities to increase the level of magnetization. Something like this was called. They produced reading sectors and the subsequent recording of the same there. Lecha Seagate from “softbad" I began to carry out the procedure of "recording zeros" from their proprietary utility SeaTool railway maintenance. As I was able to figure out, this software overwrites every information bit, bringing it to a logical zero. After this procedure, the indicator of access time to the sector, in the same MHDD, was condensed in the top lines, relative to the initial test run, to “zeroing out”. I have no screenshots with the results and this procedure is not fast and stable. On Terrabajtnik it takes more than a day, it requires forced cooling of the railway, and it does not always go to the end from the first time, falling out in DOS for unknown reasons. It is necessary to restart the procedure from the beginning and glance over the percent counter. I didn’t find an analogue of other railway manufacturers for this procedure. Once, I was able to spend a lot of time for these procedures and diagnostic test runs and made conclusions for myself. Now, all my railways, and they are only from Seagate for the reason described, before launching into working mode, I run through SeaTool. Perhaps other manufacturers have this procedure called SecureErase - I don't know if they are doing the same thing or not. Maybe someone has the information that this is nothing more than a placebo - I will not argue and persuade. Although with interest I will listen to all that is useful for health. Thanks for attention.

For NAS, I had to buy HDD 3TB WD Caviar Green IntelliPower (there were simply no other treshkas). Hands habitually took the "file" and began to "chamfer", from the eyes of the tears of resentment - seven and a half thousand for IT. Yes, "guarantee", yes, RAID5, but keep in mind the next 6-8 months rebuild of terabyte arrays ?! And then the news about the reduction of warranty periods by vendors. No, I understand very well why they reduce the guarantee - IT should not work at all. But why not improve the quality of products? However, I understand that, it’s necessary to sell a lot and not work for a long time. And then here are my three 2TB Barracudas for the second year under the 7/24 torrent are working and not beating, and Seagate is starving.

And so, if you are warming the garthalon - this topic will not be interesting for you. If you have a Seagate 7200 Constellation ES RAID6 - your time is too expensive to read such trifles. If you have spent your hard-earned money and you want "that it would not be painfully painful" - look under the cat, you can find something useful.

Long ago, when the trees were large, cold contacts were made to gild. Then gold found another use - they began to save it, and contacts, respectively, were tinned. We look, we see, we think (contacts of the block of heads).

The disc worked for an ordinary user in a beech for about 5 months and died quietly, taking all the memories of the owner with him to his grave. Whether the head preamplifier died from unstable power supply, or the controller overheated from the constant miscalculation of the CRC-Error, the warranty service is all the same - replacement. Without the possibility of data recovery or compensation for their loss. Following! The new disk looks exactly like the old one five months ago. So, this one will last to the end of the guarantee and a little more, if you're lucky. Lucky not all. View of new disk controllers that came under warranty replacement in sealed silica gel bags.

')

And this is not cheap 320s, but tops in its segment.

Calm and data integrity is more important to me.

I believe that the meaning is clear. Conventional silicone-based thermal grease is applied to well-degreased contacts. Thermal grease has two properties I need, it does not dry out and is non-conductive. I used to use KPT-8, but Zalman ZM-STG1 has a comfortable brush, like in nail polish. Back controller board is put "in one motion" - aim and vertically lower on the bank. It is necessary to avoid the displacement of contacts on the paste, so that there would be no exposed areas. If you got a product with already oxidized contacts, rub them with a soft scrub brush and brush away the crumbs, wipe with alcohol or gasoline for lighters.

After a year of operation, 2TB were enumerated.

Under Zalman-ovsky thermal grease were brilliant sites.

In a new way ...

This method has been used for more than five years. The mentioned 3TB has been modified in the same way. I hope to sell it in a couple of years, together with partners on RAID, when it becomes crowded.

Ideally, I want to find a method of “gilding” contacts at home.

The second “file completion” is prompted by the railway manufacturer itself and a hand-type gauge. When performing a large number of disk operations on an easily accessible hard disk drive, for example, connected to a USB-SATA adapter, the heating of the hard disk controller board in two places is well felt. On the inside there are located - the controller and the driver of rotational and linear motors. Between the can of railway and the controller board is laid cellophane with glued foam. A thermal strip is applied over the driver chip instead of foam rubber, and a pad is milled on the jar.

The gasket is of good quality and well adhered to the chip, but the thermal conductivity of cellophane between the gasket and the metal is a big question.

I completely remove the foam pad. The gap between the driver chip and the platform on the HDA is approximately 1 mm. I use white or blue thermal pads 1.5mm - they are elastic enough to squeeze out the excess from the place of contact. The gasket is superimposed on the chip, the board is baited with screws and it bends over the gasket. We press the board over the thermal pad before alignment and tighten the screws.

I have no experimental data on the benefits of these improvements. However, when I caught the word “fly tse-tse” and having considered the situation in general, I modified for personal consumption a dozen and a half railway and did not lose a single one in a few years. Of the several dozen modified railway that went to the side of good people, one returned. However, the over-the-counter G-sensor made it quite natural for badblocks to appear.

Good luck to all and non-surviving hard drives.

ps The original version of this post was kept for a long time in the draft, because could not be published due to a lack of you-know-what, and as a result appeared on a third-party resource. Here is published a revised and updated version of the material.

upd. This addition is for those who follow the topic, so as not to breed holivar. Once upon a time there were special utilities to increase the level of magnetization. Something like this was called. They produced reading sectors and the subsequent recording of the same there. Lecha Seagate from “softbad" I began to carry out the procedure of "recording zeros" from their proprietary utility SeaTool railway maintenance. As I was able to figure out, this software overwrites every information bit, bringing it to a logical zero. After this procedure, the indicator of access time to the sector, in the same MHDD, was condensed in the top lines, relative to the initial test run, to “zeroing out”. I have no screenshots with the results and this procedure is not fast and stable. On Terrabajtnik it takes more than a day, it requires forced cooling of the railway, and it does not always go to the end from the first time, falling out in DOS for unknown reasons. It is necessary to restart the procedure from the beginning and glance over the percent counter. I didn’t find an analogue of other railway manufacturers for this procedure. Once, I was able to spend a lot of time for these procedures and diagnostic test runs and made conclusions for myself. Now, all my railways, and they are only from Seagate for the reason described, before launching into working mode, I run through SeaTool. Perhaps other manufacturers have this procedure called SecureErase - I don't know if they are doing the same thing or not. Maybe someone has the information that this is nothing more than a placebo - I will not argue and persuade. Although with interest I will listen to all that is useful for health. Thanks for attention.

Source: https://habr.com/ru/post/137211/

All Articles