Racing technologies: Electronic Control Unit

Hello colleagues!

Today, I deviate a little from the information security topics that are traditional for me and I will tell you about electronics, with which I work in my free time: engine management systems of racing cars.

But let's start with a description of the situation as a whole. In motor sports, as in many other technical sports, quite often the result depends not only on the athlete, but also on the “projectile” that he uses. Therefore requires a professional approach to the preparation and configuration of the car. Of course, there are a lot of nuances. But if it is roughly divided into parts, it will be the chassis setting and the engine setting. Today I would like to tell you what electronics are used when working with the "heart" of racing cars.

A modern racing engine (like the engines in your cars) is controlled by a specific computer: Electronic Control Unit. He is responsible for all the processes occurring with him and manages the entire on-board electronics. The most popular solutions produced by companies such as Motec and Pectel . I use the Motec M800 in my car , by the example of which I will explain how it works.

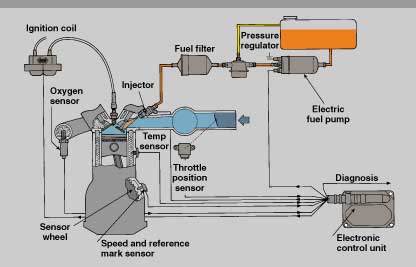

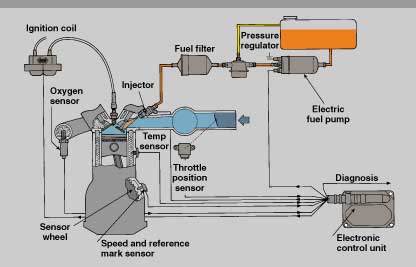

In essence, an ECU is a computer that contains engine control algorithms, tools for collecting information and the ability to control external devices. From the point of view of the algorithms of work, a 4-stroke gasoline engine is a very simple device, and it requires not much to control them. We will need knowledge of the crankshaft position (speed and reference mark sensor), throttle position and / or throttle position sensor. We also need to know the amount of air entering the engine. To do this, use the MAF (Air Flow) or MAP (Air Pressure) sensors. As control elements, we will use injectors to supply fuel (injectors) and control ignition (ignition coils). In general, the list I have listed is already enough to start the engine. The collected data allows the ECU to understand when it is necessary to feed the fuel and make it ignite. But the question remains: how much fuel should be supplied and when exactly is the ignition? But these data already represent what is called “firmware” in the jargon.

In essence, an ECU is a computer that contains engine control algorithms, tools for collecting information and the ability to control external devices. From the point of view of the algorithms of work, a 4-stroke gasoline engine is a very simple device, and it requires not much to control them. We will need knowledge of the crankshaft position (speed and reference mark sensor), throttle position and / or throttle position sensor. We also need to know the amount of air entering the engine. To do this, use the MAF (Air Flow) or MAP (Air Pressure) sensors. As control elements, we will use injectors to supply fuel (injectors) and control ignition (ignition coils). In general, the list I have listed is already enough to start the engine. The collected data allows the ECU to understand when it is necessary to feed the fuel and make it ignite. But the question remains: how much fuel should be supplied and when exactly is the ignition? But these data already represent what is called “firmware” in the jargon.

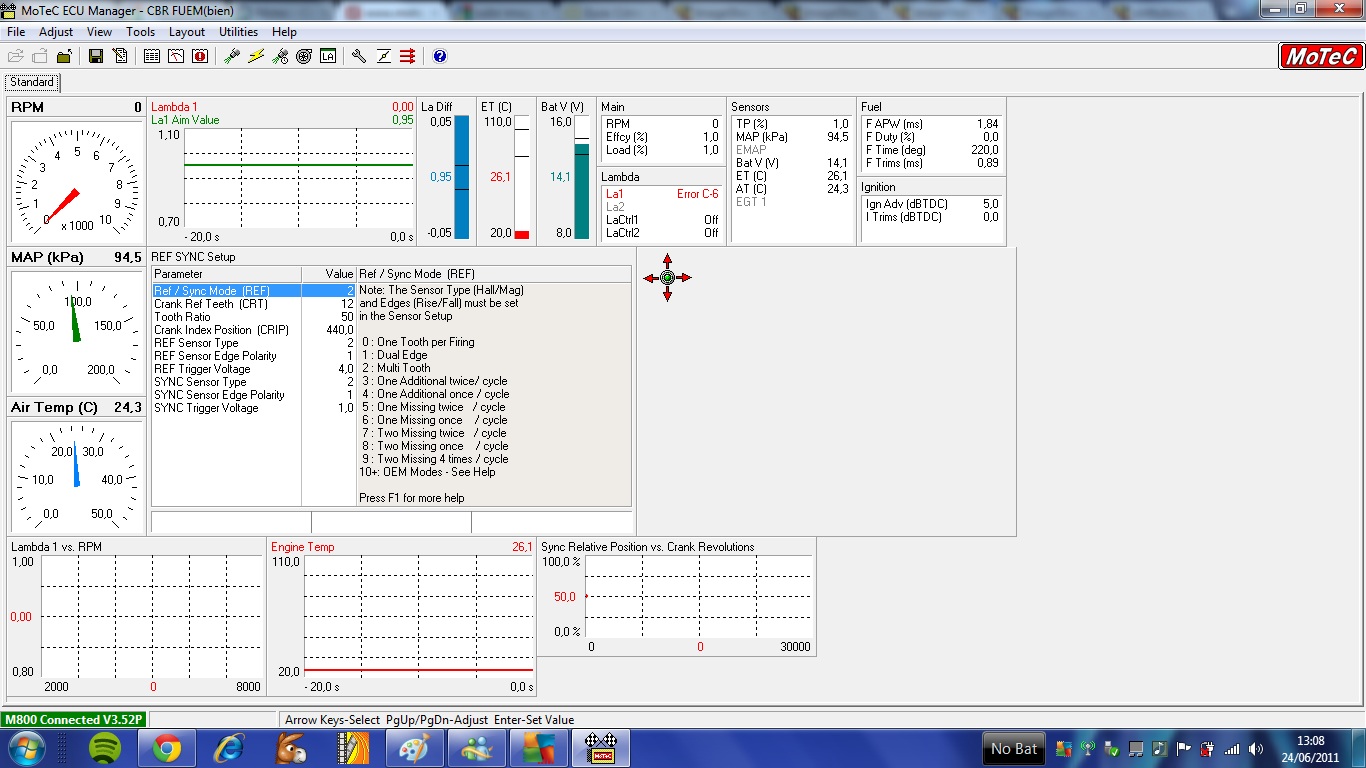

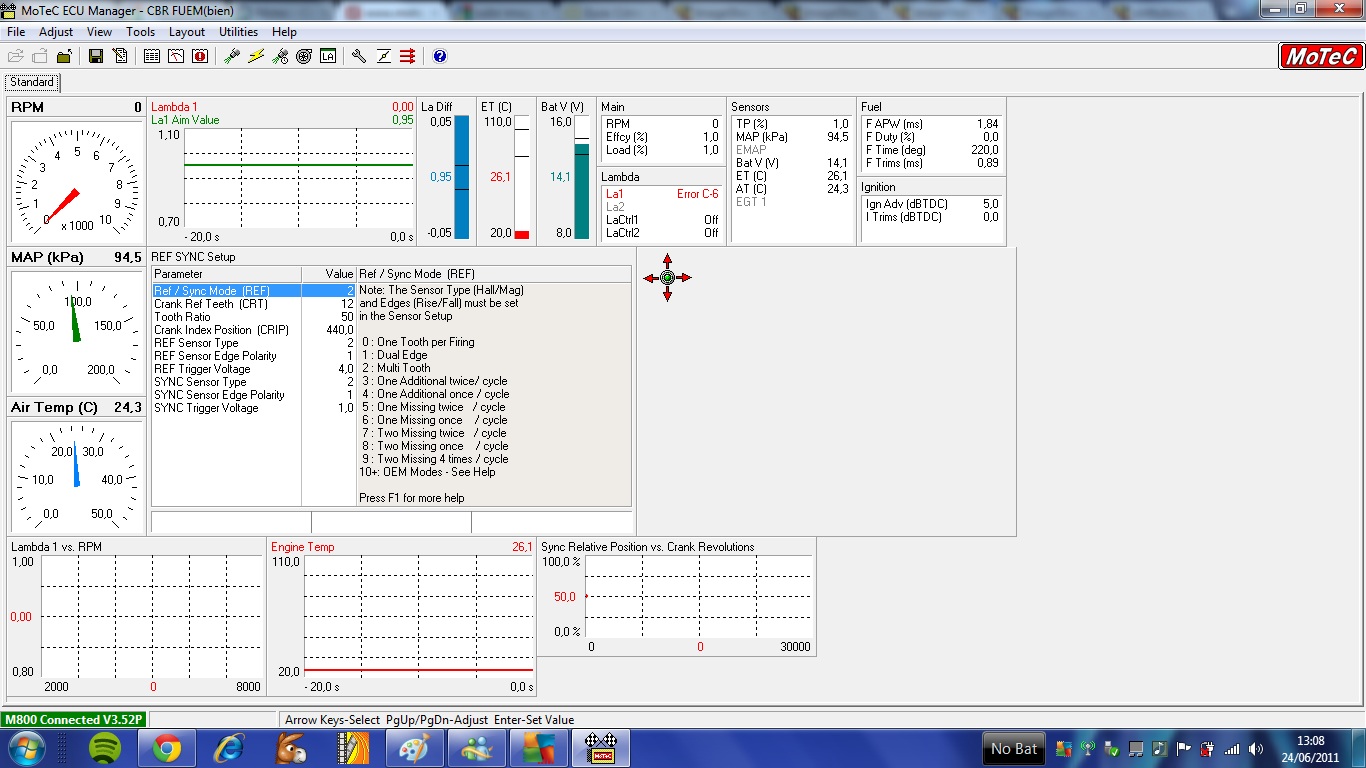

For external control, Motec computers use the CAN bus. To connect the laptop to it using special adapters CAN-to-USB . As a program for editing, ECU Manager is used , which is available for download and “training” for free on the manufacturer’s website. If you want to see how the management of the engine looks, then run WinEMP.exe with the “demo” parameter.

')

This software allows you to make adjustments to almost all aspects of the motor. One of the main parameters control algorithms is PID regulation . It describes all dynamic processes. The remaining part is implemented by functions that are described by tables. The main feature is the ability to create tabular dependencies between any available elements. Thus, the programmer is practically unlimited in the possibilities of setting the behavior algorithms. By operating the input parameters and controlling external devices, you can describe the behavior of the engine in almost any conditions.

But to monitor the work of all components of the engine "on the fly" is quite difficult. Therefore, the accompanying process is the collection and analysis of the ECU system log. Logging settings are quite rich and allow you to control all the necessary parameters. To do this, use the program i2 Manager from the same manufacturer. With its help, sensor readings are analyzed in a “calm” environment. This invaluable information allows you to accurately configure all parameters.

For communication with the outside world, the ECU has a set of incoming ports and “control” outputs. As input information, it can both receive digital signals via CAN, as well as analog information in the range of 0-12V by means of built-in programmable ADCs. A rich palette of settings allows you to customize the ECU using the GUI for almost any external sensor. Output ports mean “logical” control of external devices. But their choice is not so wide and is distributed in advance to “injectors”, “ignition” and “periphery” depending on the output characteristics. But in the end, this set of features allows you to connect the ECU to any car.

In general, it is this process of calibration and tuning of the engine that is a commercial secret of the tuning studio and racing teams. An areola of "mysteriousness" and "complexity" is deliberately created around him. But do not assume that this process is so problematic: any more or less competent programmer will cope with it, having figured out how the engine works. Just do not rush off the bat and change the ignition angles, not knowing what it is.

I hope I told you something new. Thanks for attention.

If this topic is interesting, I can describe the engine tuning process in more detail in a new article.

Today, I deviate a little from the information security topics that are traditional for me and I will tell you about electronics, with which I work in my free time: engine management systems of racing cars.

But let's start with a description of the situation as a whole. In motor sports, as in many other technical sports, quite often the result depends not only on the athlete, but also on the “projectile” that he uses. Therefore requires a professional approach to the preparation and configuration of the car. Of course, there are a lot of nuances. But if it is roughly divided into parts, it will be the chassis setting and the engine setting. Today I would like to tell you what electronics are used when working with the "heart" of racing cars.

A modern racing engine (like the engines in your cars) is controlled by a specific computer: Electronic Control Unit. He is responsible for all the processes occurring with him and manages the entire on-board electronics. The most popular solutions produced by companies such as Motec and Pectel . I use the Motec M800 in my car , by the example of which I will explain how it works.

In essence, an ECU is a computer that contains engine control algorithms, tools for collecting information and the ability to control external devices. From the point of view of the algorithms of work, a 4-stroke gasoline engine is a very simple device, and it requires not much to control them. We will need knowledge of the crankshaft position (speed and reference mark sensor), throttle position and / or throttle position sensor. We also need to know the amount of air entering the engine. To do this, use the MAF (Air Flow) or MAP (Air Pressure) sensors. As control elements, we will use injectors to supply fuel (injectors) and control ignition (ignition coils). In general, the list I have listed is already enough to start the engine. The collected data allows the ECU to understand when it is necessary to feed the fuel and make it ignite. But the question remains: how much fuel should be supplied and when exactly is the ignition? But these data already represent what is called “firmware” in the jargon.

In essence, an ECU is a computer that contains engine control algorithms, tools for collecting information and the ability to control external devices. From the point of view of the algorithms of work, a 4-stroke gasoline engine is a very simple device, and it requires not much to control them. We will need knowledge of the crankshaft position (speed and reference mark sensor), throttle position and / or throttle position sensor. We also need to know the amount of air entering the engine. To do this, use the MAF (Air Flow) or MAP (Air Pressure) sensors. As control elements, we will use injectors to supply fuel (injectors) and control ignition (ignition coils). In general, the list I have listed is already enough to start the engine. The collected data allows the ECU to understand when it is necessary to feed the fuel and make it ignite. But the question remains: how much fuel should be supplied and when exactly is the ignition? But these data already represent what is called “firmware” in the jargon.For external control, Motec computers use the CAN bus. To connect the laptop to it using special adapters CAN-to-USB . As a program for editing, ECU Manager is used , which is available for download and “training” for free on the manufacturer’s website. If you want to see how the management of the engine looks, then run WinEMP.exe with the “demo” parameter.

')

This software allows you to make adjustments to almost all aspects of the motor. One of the main parameters control algorithms is PID regulation . It describes all dynamic processes. The remaining part is implemented by functions that are described by tables. The main feature is the ability to create tabular dependencies between any available elements. Thus, the programmer is practically unlimited in the possibilities of setting the behavior algorithms. By operating the input parameters and controlling external devices, you can describe the behavior of the engine in almost any conditions.

But to monitor the work of all components of the engine "on the fly" is quite difficult. Therefore, the accompanying process is the collection and analysis of the ECU system log. Logging settings are quite rich and allow you to control all the necessary parameters. To do this, use the program i2 Manager from the same manufacturer. With its help, sensor readings are analyzed in a “calm” environment. This invaluable information allows you to accurately configure all parameters.

For communication with the outside world, the ECU has a set of incoming ports and “control” outputs. As input information, it can both receive digital signals via CAN, as well as analog information in the range of 0-12V by means of built-in programmable ADCs. A rich palette of settings allows you to customize the ECU using the GUI for almost any external sensor. Output ports mean “logical” control of external devices. But their choice is not so wide and is distributed in advance to “injectors”, “ignition” and “periphery” depending on the output characteristics. But in the end, this set of features allows you to connect the ECU to any car.

In general, it is this process of calibration and tuning of the engine that is a commercial secret of the tuning studio and racing teams. An areola of "mysteriousness" and "complexity" is deliberately created around him. But do not assume that this process is so problematic: any more or less competent programmer will cope with it, having figured out how the engine works. Just do not rush off the bat and change the ignition angles, not knowing what it is.

I hope I told you something new. Thanks for attention.

If this topic is interesting, I can describe the engine tuning process in more detail in a new article.

Source: https://habr.com/ru/post/137163/

All Articles