Lean in brief on the example of pizza delivery

In this article I will share the main ideas that I learned from the training on Lean Management, which took place in mid-December in St. Petersburg. I hope the article will be useful to those who only want to know what Lean is, as well as those who have already heard something about Lean want to get a general idea about it.

Because Lean's ideas apply to the operation of various queuing systems ; I will analyze them using the example of a pizza delivery company.

But first, briefly about the training. It was conducted by Francois Bachmann, an agile / lean coach from Europe. I met him on agileee in Kiev. We corresponded for some time, and then I invited him to read a seminar with us in St. Petersburg. Thank you ScrumTrek , who took over the organization of the training. Well, without Tanya Vasilyeva, this idea simply could not have been brought to life.

Thanks to Francois for the training. Francois has a very sound view of things and a very broad Lean-erudition. It is easy to apply to Lean ideas wherever you are: at the airport, in traffic, in a queue at a store or cafe. It seems that after the training I also became infected with it.

In general, Lean has grown out of production management practices practiced at Toyota’s factories (TPS, aka the Toyota Production System). In the late 60s, American automakers (Ford, GeneralMotor, Crysler) suddenly felt strong competition from Japanese car manufacturers, who offered cheaper and better cars to an American buyer. What was their secret? According to the sources, Mr. Deming , an American mathematician who played the mathematical apparatus under the ideas of quality control, played a significant role here. Japanese manufacturers embraced his ideas and placed emphasis on the quality and improvement of the entire production process (including Kaizen philosophy, which even pastry shops now apply). You may have read books about Toyota or heard stories about how any worker at Toyota can stop the entire conveyor if he finds an oil stain on the floor of the workshop. This is not simple - Lean says that quality cannot be achieved without reflecting on the process. The fact that Lean has much in common with agile and scrum is not surprising. The following simple picture should put things in places:

')

One of the basic concepts in Lean is value . Intuitively, value is what makes your customers' eyes burn and what ultimately brings money to your company.

For Toyota, these are sold cars, and in our example sold pizzas.

As experience shows, sometimes it is not too much to synchronize the understanding of the value produced within the team (company). Swan, cancer and pike differently understood the value, so Lean did not go.

It is clear that the value is formed in stages. First, the operator takes the order from the client. Then he passes it to the cooks. They make pizzas and give them to a peddler who delivers them to the customer and accepts payment. Each stage adds value to the result.

As I said before, Lean deals with queuing systems. And they all work with the flow of applications. This may be the flow of cars on the highway, the flow of customers in the store, the flow of product requirements. We will consider the flow of pizza orders.

So, go ahead! Let's look at pizza delivery from the point of view of Lean. To increase business profitability, we need to increase productivity, i.e. process more orders per day (we assume that there is room for growth). This can be achieved by different methods. For example, increase attendants. But the wise Japanese (as well as common sense) say that you need to begin the path to real efficiency by reducing the order processing time. Those. with tuning system.

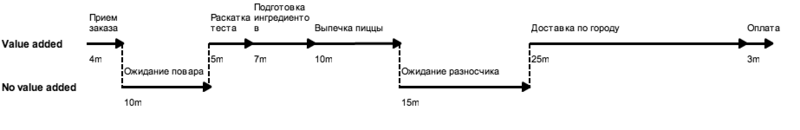

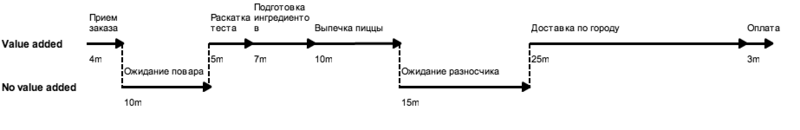

Where to begin? Buy advanced equipment for quick kneading dough? Or invest in the navigator razvozchiku? In order not to fall into micro-optimization, we will create a simple scheme, which in Lean is called value stream map. For simplicity, we will assume that we are considering a “typical” order.

Total order service time took 1 hour and 4 minutes.

In the diagram, we immediately separate the phases that contribute value from the unprofitable. It is clear that steps 2 and 6 fall into the second category. By eliminating them, it would be possible to reduce the order processing time by 25 minutes! In Lean, there is a special term for about ... wasted time and effort - waste . In short, the loss can be safely issued as the Nth sum, thrown to the wind.

Having such a picture, it becomes clear which steps to optimize. It is necessary to get rid of waste completely. Starting with the optimization of the order acceptance phase hardly makes sense. But reducing the delivery time from 25 to 15 minutes (for example, transferring to a motorcycle) is an achievement.

What's next? It is necessary to follow how the queues of orders behave and the time of order servicing when you make changes. With good accuracy to inform the customer how long the pizza will be delivered. Understand in which case it makes sense to stop taking orders, because the processing time will be too long. A lot of interesting!

In conclusion, I will give a classification of losses. Although the Japanese did it for the car assembly process, the classification is perfect for both pizza delivery and software development.

It was easier for me to remember the loss names in the English version (the first letters make up the word downtime):

Let us examine them by examples.

So let's summarize.

Lean is a look at things that helps to see problems in the process and solve them with the help of practices and tools (value stream mapping, gemba, kanban, scrum).

Lean is a philosophy of continuous improvement at all levels of the organization (kaizen, 5S).

I hope reading the article has not become a waste for you.

Because Lean's ideas apply to the operation of various queuing systems ; I will analyze them using the example of a pizza delivery company.

But first, briefly about the training. It was conducted by Francois Bachmann, an agile / lean coach from Europe. I met him on agileee in Kiev. We corresponded for some time, and then I invited him to read a seminar with us in St. Petersburg. Thank you ScrumTrek , who took over the organization of the training. Well, without Tanya Vasilyeva, this idea simply could not have been brought to life.

Thanks to Francois for the training. Francois has a very sound view of things and a very broad Lean-erudition. It is easy to apply to Lean ideas wherever you are: at the airport, in traffic, in a queue at a store or cafe. It seems that after the training I also became infected with it.

In general, Lean has grown out of production management practices practiced at Toyota’s factories (TPS, aka the Toyota Production System). In the late 60s, American automakers (Ford, GeneralMotor, Crysler) suddenly felt strong competition from Japanese car manufacturers, who offered cheaper and better cars to an American buyer. What was their secret? According to the sources, Mr. Deming , an American mathematician who played the mathematical apparatus under the ideas of quality control, played a significant role here. Japanese manufacturers embraced his ideas and placed emphasis on the quality and improvement of the entire production process (including Kaizen philosophy, which even pastry shops now apply). You may have read books about Toyota or heard stories about how any worker at Toyota can stop the entire conveyor if he finds an oil stain on the floor of the workshop. This is not simple - Lean says that quality cannot be achieved without reflecting on the process. The fact that Lean has much in common with agile and scrum is not surprising. The following simple picture should put things in places:

')

One of the basic concepts in Lean is value . Intuitively, value is what makes your customers' eyes burn and what ultimately brings money to your company.

For Toyota, these are sold cars, and in our example sold pizzas.

As experience shows, sometimes it is not too much to synchronize the understanding of the value produced within the team (company). Swan, cancer and pike differently understood the value, so Lean did not go.

It is clear that the value is formed in stages. First, the operator takes the order from the client. Then he passes it to the cooks. They make pizzas and give them to a peddler who delivers them to the customer and accepts payment. Each stage adds value to the result.

As I said before, Lean deals with queuing systems. And they all work with the flow of applications. This may be the flow of cars on the highway, the flow of customers in the store, the flow of product requirements. We will consider the flow of pizza orders.

So, go ahead! Let's look at pizza delivery from the point of view of Lean. To increase business profitability, we need to increase productivity, i.e. process more orders per day (we assume that there is room for growth). This can be achieved by different methods. For example, increase attendants. But the wise Japanese (as well as common sense) say that you need to begin the path to real efficiency by reducing the order processing time. Those. with tuning system.

Where to begin? Buy advanced equipment for quick kneading dough? Or invest in the navigator razvozchiku? In order not to fall into micro-optimization, we will create a simple scheme, which in Lean is called value stream map. For simplicity, we will assume that we are considering a “typical” order.

- Reception of the order took 4 minutes.

- Next 10 minutes the order was waiting for the cook to finish serving the previous order.

- It took 5 minutes to prepare and roll out the dough.

- 7 minutes - to prepare the ingredients.

- 10 minutes pizza was in the oven.

- 15 minutes of pizza were waiting for the peddler.

- 25 minutes peddler traveled through the city to the client.

- 3 minutes took the order payment process.

Total order service time took 1 hour and 4 minutes.

In the diagram, we immediately separate the phases that contribute value from the unprofitable. It is clear that steps 2 and 6 fall into the second category. By eliminating them, it would be possible to reduce the order processing time by 25 minutes! In Lean, there is a special term for about ... wasted time and effort - waste . In short, the loss can be safely issued as the Nth sum, thrown to the wind.

Having such a picture, it becomes clear which steps to optimize. It is necessary to get rid of waste completely. Starting with the optimization of the order acceptance phase hardly makes sense. But reducing the delivery time from 25 to 15 minutes (for example, transferring to a motorcycle) is an achievement.

What's next? It is necessary to follow how the queues of orders behave and the time of order servicing when you make changes. With good accuracy to inform the customer how long the pizza will be delivered. Understand in which case it makes sense to stop taking orders, because the processing time will be too long. A lot of interesting!

In conclusion, I will give a classification of losses. Although the Japanese did it for the car assembly process, the classification is perfect for both pizza delivery and software development.

It was easier for me to remember the loss names in the English version (the first letters make up the word downtime):

- Defect

- Overproduction

- Waiting

- Not using employees creativity

- Transport

- Inventory

- Motion

- Extra processing

Let us examine them by examples.

- With defects everything is clear. Cold pizza is a bug. A normal client will simply refuse it.

- Overproduction is when we produce more pizzas than we can sell. But it is unlikely that someone will do it. Therefore, another example is when we decided to make a surprise and present Hawaiian pizza “as a gift”

- Losses to wait, we looked.

- If we do not use the talents of employees, we lose! This is a topic for a separate article. In the meantime, and so it is clear that if the cook comes up with a suggestion of how to diversify the menu, and the peddler comes up with how to speed up the delivery (for example, switch to a motorcycle), it makes sense to listen to them.

- Transport is interesting not only in the literal sense. Information transfer is also a transport. Suppose your cook is sick, and it is replaced by a new inexperienced. Once with me it was once in the clinic, the ENT examined me by following the instructions on the phone.

- Inventory is the cost of storage and accounting. For example, vegetables, if we bought them for the future. Accounting for simultaneously processed orders from customers is also an inventory. A large number of orders that are in simultaneous processing (work in progress) result in context switching costs. This is where kanban technology comes to the rescue, limiting work in progress.

- Excess movements can often be avoided by arranging the workplace in the right way. In addition, honing the movement, you can multiply the performance. Professionals know this, surpassing the speed of cutting the products of ordinary mortals by an order of magnitude. You can avoid unnecessary motion by following the rules of 5S.

- Suppose we decided to please our customers and cut ham in the shape of snowflakes. If this is not our competitive advantage, we lost to extra processing.

So let's summarize.

Lean is a look at things that helps to see problems in the process and solve them with the help of practices and tools (value stream mapping, gemba, kanban, scrum).

Lean is a philosophy of continuous improvement at all levels of the organization (kaizen, 5S).

I hope reading the article has not become a waste for you.

Source: https://habr.com/ru/post/136458/

All Articles