Russian microelectronics for the military industrial complex and not only

I have long wanted to see how and where they produce the element base for our world-famous weapon. It seemed that it was terribly closed objects, which I would not be allowed on a sniper shot. I remember when I was in NIIAR in Dimitrovgrad , everything is serious there, the military with machine guns, barbed wire, roadblocks. There is nothing like this. As it turned out, to get to such an object is quite simple. In the company " Milandr " vividly responded to my request to make a photo-report about them, and I, as soon as I had free time, went to the Russian Silicon Valley - the city of Zelenograd.

')

The Milandr company was formed in the early 90s, but until 2003 it was engaged only in the sale of microchips. But by the beginning of the 2000s, an understanding had arisen that you could not go far to buy and sell. Therefore, it was decided to acquire its own production, and most importantly - own development, as R & D says now.

There are 4 classes of chips, by application. The easiest is commercial. On the one hand, this is the widest market, on the other hand, the most elementary requirements for reliability. In fact, such chips should work normally at room temperature, under normal conditions. The next class - industrial - requirements for working conditions more stringent. The military class microcircuits already have much more stringent requirements both in temperature and in many other parameters. And aerobatics - space class microcircuits - for space applications.

Milandr mainly works in the military class, but a little in two neighboring areas. For example, their chips are in the GLONASS satellites - this is space. The company also enters the commercial market, especially now it is developing in the electricity metering market, cooperating here not only with Russian companies, but also with foreign ones. There are developments in other areas - for example, special speed sensors for tachographs, which allow to take into account the time of work of drivers - truckers. This is necessary, so that they do not recycle, such control reduces the risk of accidents.

Another direction of the company's development is the informatization of medical institutions. Implemented an automated system in one of Zelenograd polyclinics.

But the main direction is the MIC. The company is especially proud that the Milandr production chips are in the newest Russian fighter jets, and the memory produced by the company is used in the air defense complexes.

The company also licensed the core ARM, which allows you to expand your presence in the market of microcontrollers, to create complex systems on a chip.

The market of "military" circuits in Russia is about 3 billion rubles. Almost all of it is occupied by our companies and Belarusian Integral. “Milander” is still a small player here - just under 200 million rubles. But the company works with profit, develops new directions, and has the main thing - its own development department. Now the company has more than 400 clients.

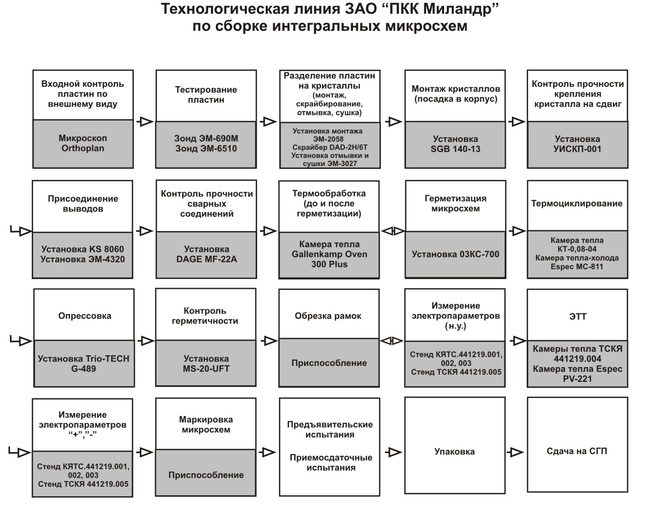

The production process is built as follows:

* The microelectronic device is developed by the company's engineers in the development center.

* Next, the design documentation is transferred to one of the outsourcing factories, where silicon wafers are created using 0.18 micron technology.

* Not measured semiconductor plates come back, here on the equipment of the company they go through the remaining technological operations: scribing, boarding, sealing, testing, measuring parameters, marking and so on.

Of course, it is a pity that not all stages are implemented in the enterprise. It does not make sense to establish crystal production in oneself, due to the high cost of living, the huge space required, and the overall economic inexpediency for the company at this stage of development. But on the other hand, the production of microcircuits using 0.18 micron technology is, according to modern times, no news of what high technology. For the market in which the company operates, especially for the military industrial complex, more is not needed. Need a more modern technical process? This is not a problem, just order. There are no dependencies here either, it’s not a problem to choose any factory - including in Russia, if someone suddenly refuses to cooperate. The remaining technological steps - the company takes over.

The life of the chip begins here.

This is the Integrated Circuit Design Center. The situation, I must say, home. I imagined otherwise, but it turned out to be a little different from my workplace :)

I must say that the center is developing chips, not only for themselves. The company also sells intellectual property for export.

Next, clean room

general view of the assembly and measurement production

This is the hall of measurements, then passes testing, testing and certification of products. The hall is equipped with modern equipment, almost all operations are automated. Here we will return, and now the production department. Here there is a cutting of the plates into crystals, landing in the body, etc.

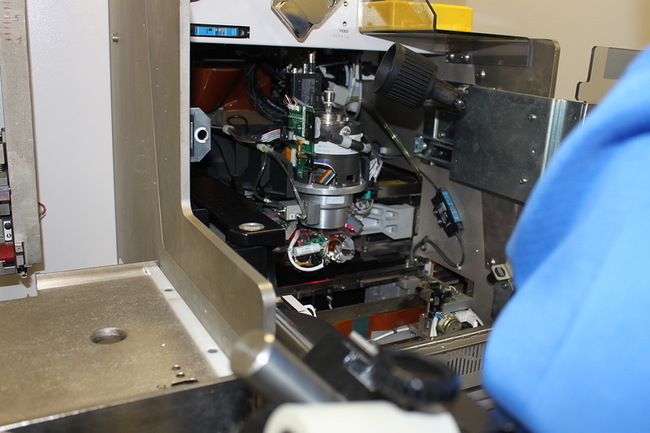

Diamond cutting plates

Semi-automatic equipment for landing the crystal in the case

Rollerless sealing installation

Attaching conclusions

Next, the crystals should be tested and tested. Since these are products for the military, the requirements for them are the most severe.

Automatic probe setup for testing semiconductor wafers. There are two of them.

Installation "Thermostrim". Here, chips are tested at different temperatures. The installation allows for a couple of minutes to change the temperature from + dofig to dofig.

Here is a spectacular shot.

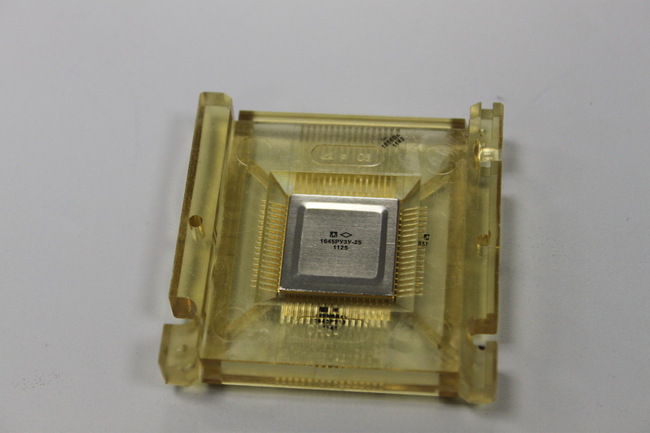

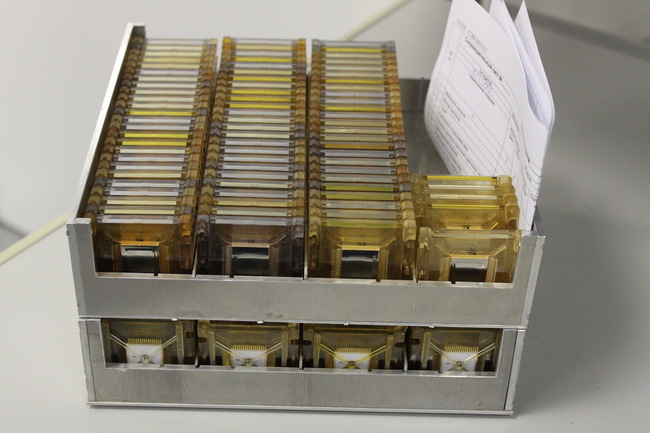

After a lot of operations, and bullying of the chips, about such products are obtained.

This is a memory. Chip 512 KB. If to compare with consumer memory modules, the chips of such a volume were installed on the memory bars in the 98th year. 8 on the one hand and 8 on the other. The result was a SIMM 8 megabyte plank. Remember? That's just this chip is able to work in such conditions that have not dreamed of that consumer goods that are in your computers. But he stands ... 8 500 p apiece. And take the same!

But so much is this particular chip. There are chips for the consumer market, in plastic cases, 165 rubles each.

These products protect our peaceful sleep and the peaceful sky above.

Well, the rumors about the death of our microelectronic industry have been greatly exaggerated.

Source: https://habr.com/ru/post/134083/

All Articles