Hifidiy A20. Putting the power amplifier

* Stock photos are used in places because of their lack of proper quality. Caution! There is a carpet on the photo, not to look at the carpets :) A lot of big photos, traffic!

Greetings As promised, I will talk about how I collected the speaker for acoustics. Since the industrial options did not suit me, I aimed my choice at the diy options. The amplifier will be used with bookshelf highly sensitive acoustics, I decided that I would assemble an amplifier with a power of 15-30 watts, always in class A (Yes, yes, instead of a heater). I went through a lot of projects, stopped at the Krell KSA 50 clone - HifiDIY A20. He completely arranged for me, with power, dimensions, components. And I started the assembly.

Some technical characteristics:

')

Frequency range : 5-100K

Output power (8 ohm load: 25 watts (B A class) 100 watts (B AB class).

Distortion: 0.01%

Sizes (in centimeters): 25 * 13 * 32

Weight: 13kg

Purchase:

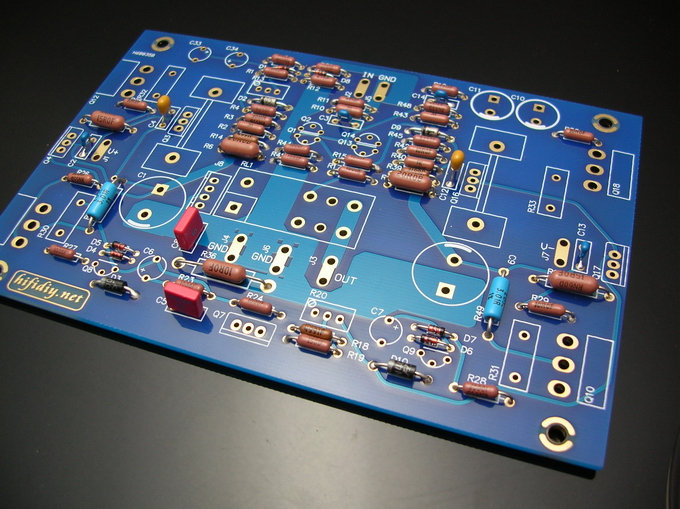

Everything is standard, ordered, paid, and in eighteen days received such beauty:

Fortunately, the packaging was excellent, there was not a scratch on the amplifier, and the box clearly played football, but as usual.

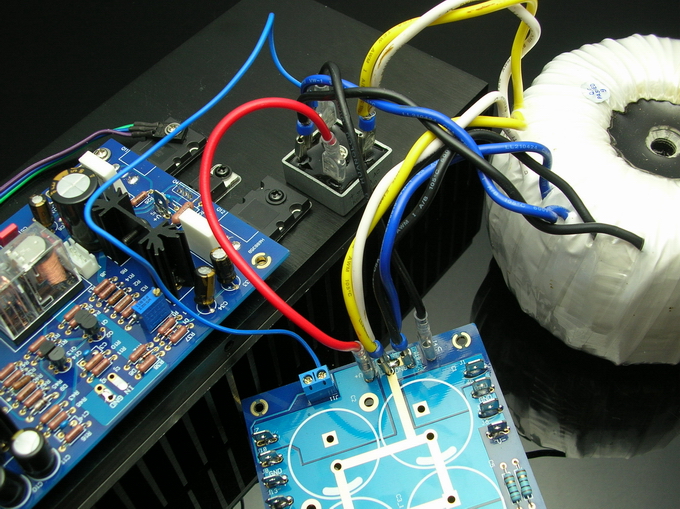

Power supply assembly:

The power supply is made according to the standard scheme, the upc1237 chip is used as protection, it is this one, because it requires minimum strapping and is quite reliable. The total filter capacity 88000 mKf. A universal transformer, two primary sources of 110 each, for our networks, it is necessary to connect in series, and four secondary devices of 16 volts per 6 Amps.

So connect the windings:

And more clearly:

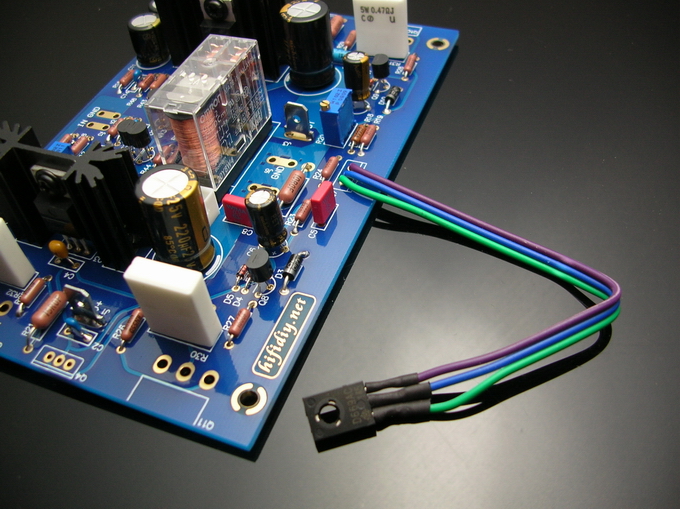

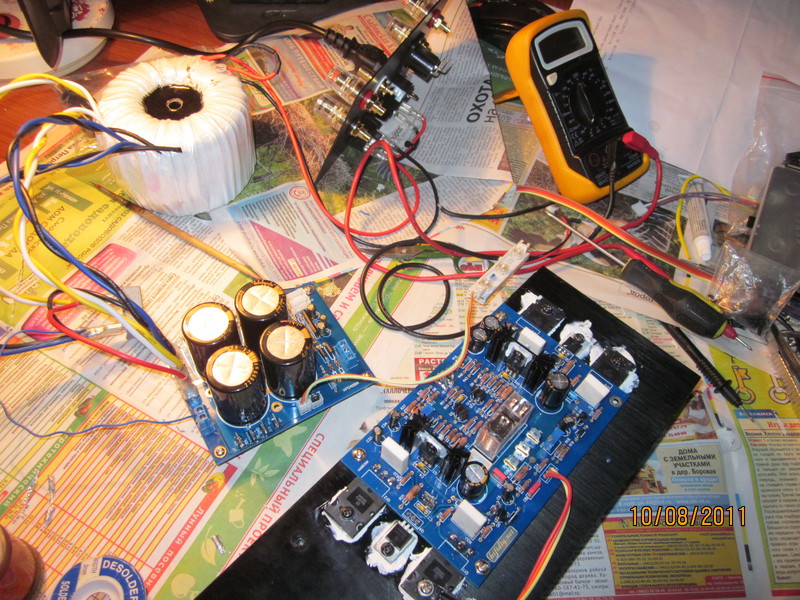

It all started right away, in fact, it could not have been otherwise :) We are starting to collect amplification boards. I plan to soon put the software start, so as when charging capacities the power supply unit works in almost short circuit.

Assembly of the amplifying part:

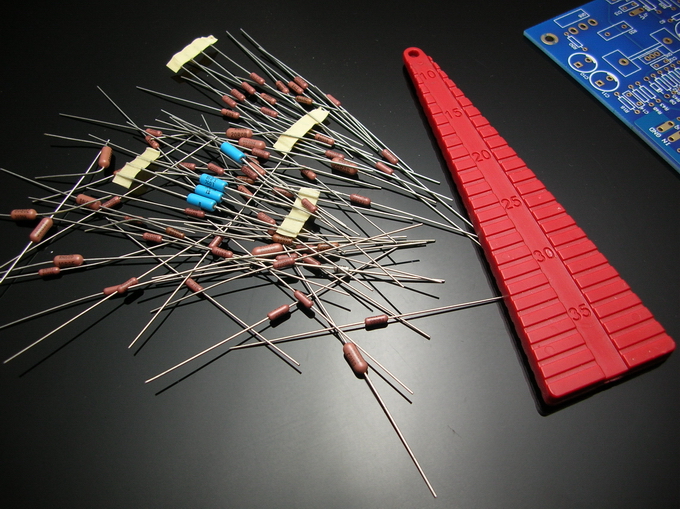

The amplifier is assembled on fairly high-quality components, capacitors nichicon muse, resistors 1% dale, relay omron.

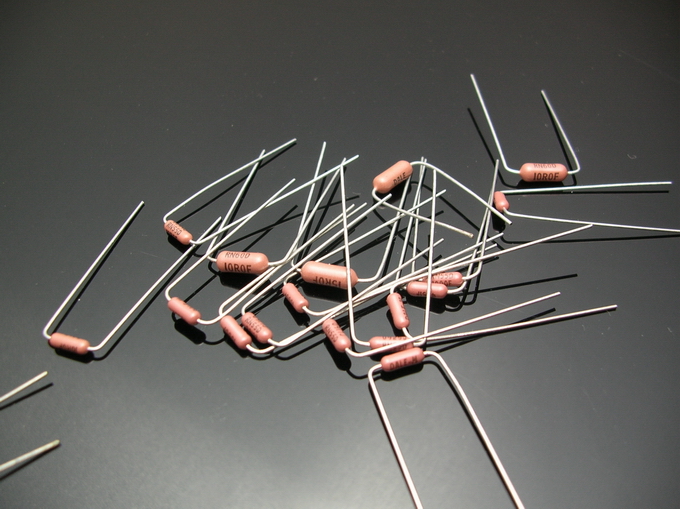

Everything goes according to the usual principle, from small to large, for the beginning we will prepare a board and form resistor terminals

Soldered resistors, solder capacitors, diodes (do not confuse the direction of inclusion) and zener diodes (also do not confuse :))

Now the output transistor emitter capacitors and resistors

Power terminals must be sealed from two sides, and that is, the risk of tearing, the terminals are worn tightly.

Now the missing transistors, relays, variable resistors.

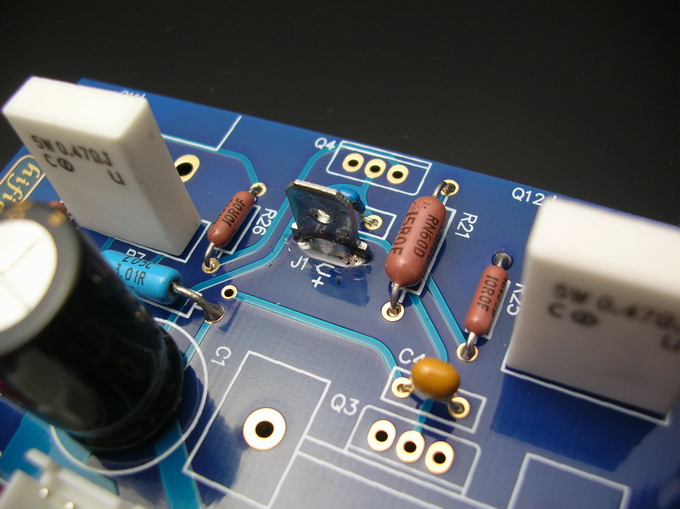

Now we put the thermal stabilization transistor, mounted on the output.

I will not write about the preamplifier, although there is a version with it, but I have a clean helper and I did not collect it.

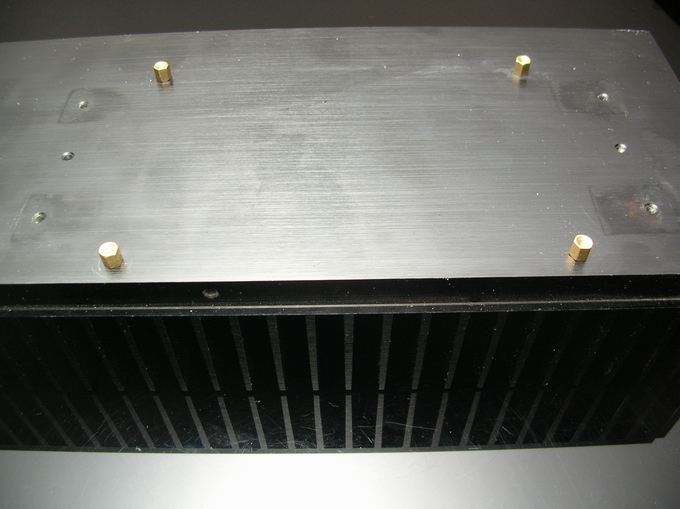

Cooking radiator, you can degrease and wipe with alcohol, screw the rack.

Fitting:

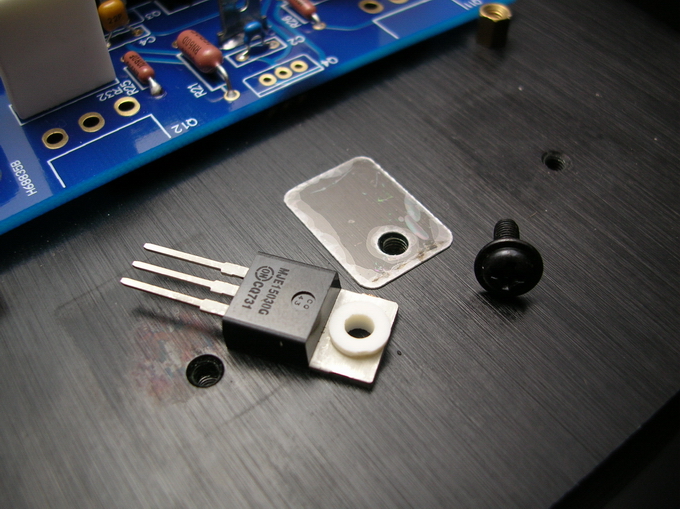

Do not forget about the sleeve and the substrate:

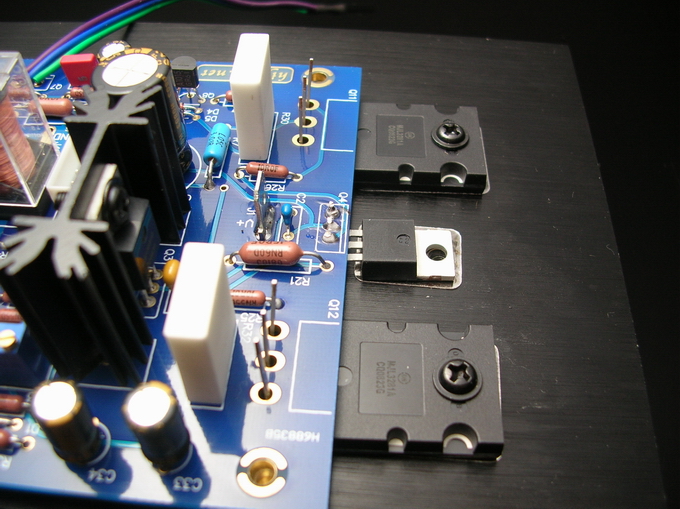

Now install the output transistors, also do not forget about the substrate, the sleeves are no longer needed.

Do not forget to fix the thermal stabilization transistor and the diode bridge:

Preparation for the test launch was completed, assembled, turned on, there was no noise, no crunch, cod, hmm, after a couple of seconds the smoke started from v +, I was very lucky that the flux burned and not a piece of track on the board. I’ve probably checked everything five times, I can’t find a mistake, with a bad mood I put off the assembly the next day. Then it dawned on me in the morning, it would be necessary to check the output, I didn’t confuse npn with pnp, as it turned out I confused, yes, shame, but what to do, redid it and the amplifier started up immediately. Hooray!

Ready board :)

Now you need to turn on the design and adjust the quiescent current and zero at the output, set a zero, then a quiescent current: I have 500 mA per transistor, 2A per channel, and more, but at room temperature +23 degrees, the body warms up to 50-60 degrees and this is not the limit :) The quiescent current is set at resistor R20, the value is measured between d6 and q10. First you need to set a lower value than necessary, with the heating of the structure, the rest current creeps upwards, you need to warm up the amplifier to the operating temperature for half an hour, and only then set the current, after setting the current, set the output to zero, it is regulated on resistor R13 , and the current value is measured between r21 and j4. That's all, setup is complete, it's time to assemble the amplifier in the case.

Putting the body:

To begin with, we will assemble the back panel, I did not connect the xlr, but the amplifier can also be used with a balanced connection, only two amplifiers are needed, one per channel. I liked the switch very much, it opens the phase and zero immediately, it is very convenient not to grab at any time during the assembly.

Screw the legs to the chassis and put the power supply:

We are starting to assemble the chassis, the layout is VERY dense, it turned out that at the end of the assembly I did all the operations with tweezers.

It turned out like this:

The power wires were taken as far away from the signal wires as possible, using shielded wire, a 2.5 sq. M cable was supplied to the output terminals, which is enough in general. There were no fasteners for the indicator backlighting; I just attached it with signal ties to the signal. Glass with logo pasted superglue. The wire to the output connectors is soldered very tightly, I even had a 70-watt soldering station stuck :) So you need an old-fashioned tin for buckets :)

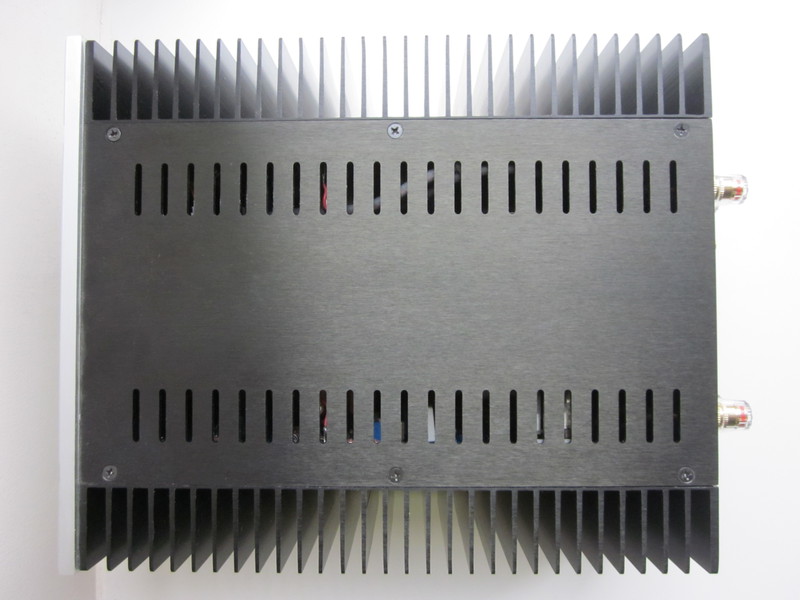

Results:

The amplifier turned out to be not big but heavy, but with a great sound, it will delight me with its sound on cold evenings, 360 watts of heat dissipates on the body, after all :)

Scheme:

1. Amplifier

2. Power supply

Ideas for improvement

- - In the OOS circuit there are 2 polar electrolytes connected by pluses, replace them with high-quality non-polar electrolyte (Something like Nichicon ES)

- - Current sources for input diffkaskad - 2 resistors and a zener diode - replaced by something on the transistor.

- - Add soft-start.

Finished product

Thanks for attention! Any questions will be answered in the comments.

Source: https://habr.com/ru/post/132689/

All Articles