3D printing event (ending)

3d printing event

Outside the article about the first event in the Netherlands on 3D printing, there are a few unlighted moments and photographs. And habrazhiteli showed considerable interest to the topic, so I can not share the remnants of information. It will be about 3d printing of jewelry, food and sculptures.

Soft is not the last thing.

At KDPV, the result of the operation of the selective laser sintering machine ( SLS ) is higher. With these air structures, netfabb demonstrated the capabilities of its software. By the way, they have a free version of the program netfubb Studio Basic , which is popular among fans. The program allows you to view stl files for printing, to operate in parts, cut into layers. On their website you will immediately see a tree in the background image. This is a huge tree measuring 2.4 meters in height and with a 3.4m crown diameter cheated on their software. Data in .stl format weighs 1Tb. 10 computers working in parallel 6 hours cut the model into layers. And then the tree for printing was divided into 7 parts, which eventually printed 340 (!) Hours. For a modest sum of 70k € you can buy it for your winter garden :)

Jeweler

The Aures printer of the German company envisiontec GmbH prints with jeweler precision. The resolution on the XY axis is 0.043 mm, and on the Z axis - 0.025-0.035 mm, depending on the material. But slow-nnnnnnnnn-no: 3-7mm per hour. The principle of work here is slightly different. Prints from materials on the basis of the resin, which hardens under ultraviolet light. That is why it is necessary to cover the printing area with such a wonderful cap - so that parasitic illumination does not occur. Products are obtained with glory - elaborate details, smooth surface:

')

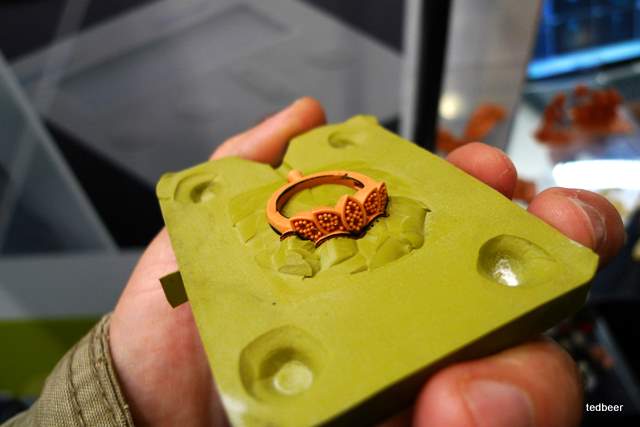

Then the model is used to make a mold for casting:

Since the process is slow, and the area allows, then several copies are made at once.

After casting, all that remains is to polish, insert the stones (or not to insert) and that's it!

The elaboration of details is simply incredible:

And you will not believe, but there is a fan who has independently manufactured a similar machine with comparable characteristics. I even thought at first that it was his machine at the exhibition, but apparently he just saw professional designs and repeated. True, while he is not eager to share the details of the structure. Although what are the details here? The same 3 measurements, slowly drive the UV flashlight, shine it into the resin bath, and as it solidifies, immerse the model or not just immerse, but wet the surface, and then raise it to light. Well, optics still need to count / adjust.

Architecture

If a little work on the increase in the machine, you can grow up to print small architectural forms. Although only Zurab Tseriteli can call it “small”.

After a brief introductory word from a representative of Rhinocentre, a nondescript little man stepped onto the stage. Such a hard worker with rough hands. In Russia, he would most likely be the owner of an old, deserved penny, or at least a six, would have drunk in the evenings in the garage with friends. He turned out to be a sculptor :) He demonstrated how easily and naturally he makes sculptures on a computer using Rhino software, said that they print a small model on the spot, and then they send a task to Italy to print a full-sized sculpture there. Then she is taken back to the workshop, brought to mind and set to the customer.

Models and sculpture:

Printer:

One of the sculptures in place:

Food stamp

There is such a topic. I can not tell in detail about the printing of food, because it was physically impossible to visit all the reports - they went in parallel in two halls, and I missed food devoted to it :) But I got acquainted with the materials of TNO. In fact, they do not have some kind of killer product. They have learned from edible to make microfibers, microspheres and microcapsules. The size of these structures is in the submillimeter range.

They call their design as a print head - a head with 500 nozzles, which allows to process liquids and other materials at high speed. Accordingly, you can then print the final product by combining the necessary proteins, fats and carbohydrates in the desired useful proportions. In fact, the food may have the characteristics of fatness / nutritional value on an individual basis. They are also played with laser sintering of sugar, printing of chocolate chains, etc.

Printing chocolate on amateur machines.

But people do not want to wait. And many are already trying to print chocolate by constructing a special supply or using different workarounds.

The main difficulties are careful control of the temperature, the flow of chocolate and its slow freezing. Machines sharpened on the supply of plastic in the form of a thin bar with a diameter of 3mm or 1.75mm. I met an original solution - instead of an extruder, a syringe is attached, and a plastic bar presses on the piston and squeezes out chocolate paste or silicone, for example, which can also be filled into a syringe.

In general, there are a lot of areas where 3D printers can open a new niche.

Source: https://habr.com/ru/post/131623/

All Articles