Features and benefits of free cooling technology in the EcoBreeze data center cooling system

At the end of September, APC by Schneider Electric held a press conference in Moscow dedicated to the start of deliveries to Russia of the modular EcoBreeze cooling system. This system is ideal for countries with a cold climate and is the most energy efficient solution among all currently known options. The use of EcoBreeze for cooling large computer centers, can significantly reduce the need for electricity and reduce maintenance costs of the system itself. What is the EcoBreeze solution, and what role does “free cooling” or free cooling technology play in improving cooling efficiency? Let's try to figure it out.

At the end of September, APC by Schneider Electric held a press conference in Moscow dedicated to the start of deliveries to Russia of the modular EcoBreeze cooling system. This system is ideal for countries with a cold climate and is the most energy efficient solution among all currently known options. The use of EcoBreeze for cooling large computer centers, can significantly reduce the need for electricity and reduce maintenance costs of the system itself. What is the EcoBreeze solution, and what role does “free cooling” or free cooling technology play in improving cooling efficiency? Let's try to figure it out.Before we consider directly the EcoBreeze solution itself, let us recall the interesting features of modern data center cooling systems. Most of them have pretty high power consumption, because Most of the time a compressor is involved.

Until recently, even the best data centers had an energy efficiency ratio of about 1.6, and the worst showed an indicator of 3. The PUE (Power Usage Effectiveness) ratio of the total power supplied to the data center to the useful power reached the consumer) means that every kilowatt consumed by servers, another 2 kilowatts are uselessly eaten by engineering systems because of the inefficiency of their work.

')

It is not uncommon for such data centers in which air conditioning fans, delivering air to servers through a narrow space, consume more electricity than the racks with servers they cool.

A year ago, it was simply impossible to obtain an energy efficiency ratio less than 1.3 or 1.4 on the most efficient technologies that have gained industrial distribution. At the moment, thanks to the EcoBreeze solution, this indicator has been reduced to a value of 1.25.

The main engineering systems that ensure the functioning of the data center and consume the most energy, are the power supply system and air conditioning system. Over the past few years, the power supply system has completely changed and at the moment its contribution to the total energy loss is minimal. At present, the data center’s energy security is provided by UPSs with very low losses, the efficiency of which is about 97–98%. Thus, in addition to computing systems, the main contributor to the overall power consumption of computing centers is the cooling system. And it is the transformation of this system that will reduce energy costs and improve energy efficiency.

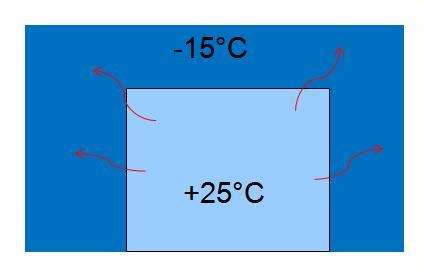

How can you improve the efficiency of the cooling system and at the same time reduce energy consumption? The solution turned out to be simple - for cooling servers it is cheaper to use the cold air of the environment. This technology is called "natural cooling" or free cooling (free cooling), and it is based on air heat transfer without mixing the outside and inside air.

Freaking

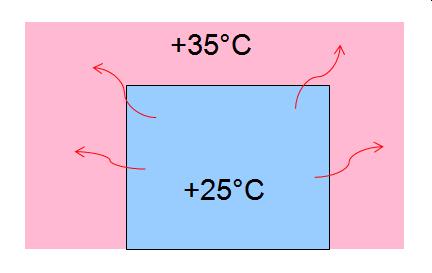

At high outside temperatures: Carnot cycle (compressor)

At low ambient temperatures: free heat transfer from a more to less heated environment

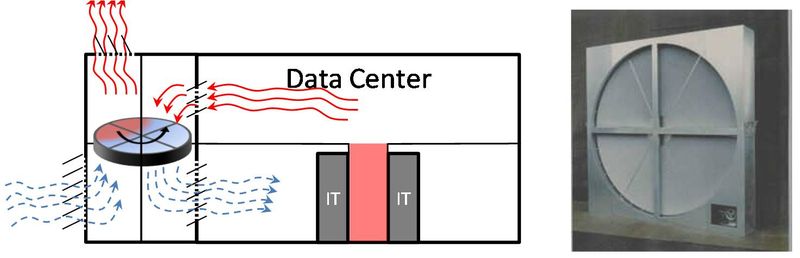

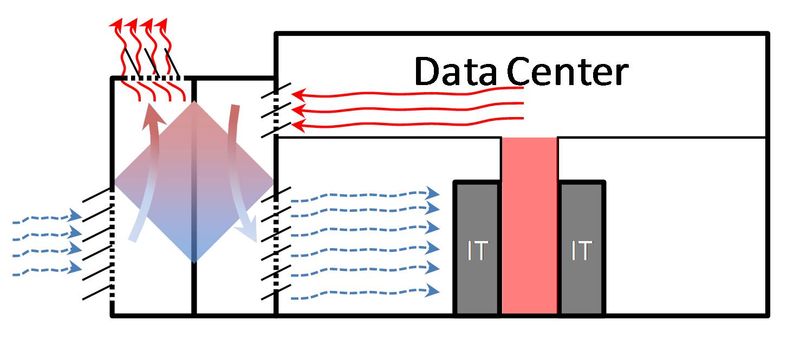

There are several free-cooling implementation schemes reflected in the illustrations below.

Examples of freeguing implementations:

Freekuling using outside air

Free cooling with precision air conditioner with two heat exchangers

Heatwalking using a heat wheel

EcoBreeze combines the best free cooling technology and takes advantage of the local climate. Depending on the situation, the system can automatically switch to one of three cooling methods.

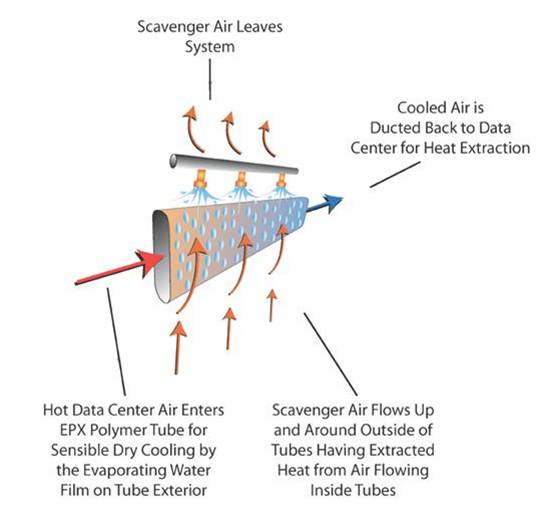

Direct air heat exchange - hot air from the data center's computer equipment is pumped by electronically switched fans through the internal channels of an indirect evaporative cooler (IEC). After the initial cooling, the air from the computer equipment leaves the IEC, passes through the heat exchanger of the cooling system and returns to the data center.

Direct heat exchange scheme

Indirect evaporative heat transfer - the heat from the air coming from the room of the data center is removed due to the evaporation of water on the outer surface of the air-to-air heat exchanger channels.

Scheme of evaporative heat exchange

• Heat is removed by evaporating water on the outside of the heat exchanger channel.

• Water is supplied evenly by spray nozzles over the entire area of the heat exchanger.

• Supports air amount adjustment

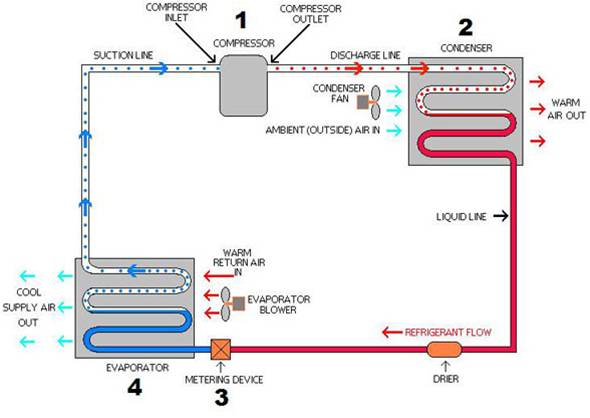

If the ambient temperature exceeds the threshold of 7 ° C (this value can be adjusted depending on the parameters of the air in the data center) additional irrigation is connected, and at a temperature of 27 ° C (the value can also change depending on the data center parameters) the proportional freon circuit is connected.

Proportional contour circuit

• Compressor with variable power allows you to achieve optimal efficiency of freon cooling

• Complements evaporative cooling to maintain supply air temperature.

• Designed for 60% full load.

• Refrigerant freon R410a

Thus, at low temperatures, the system dispenses with and without water, and without freon, working only on the ambient air. When the temperature and the amount of outside air are not enough to maintain the set temperature of the air supplied to the data center, the irrigation system is connected. If the connected system with additional irrigation stops providing the specified temperature, the compressor system takes effect.

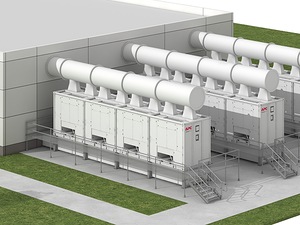

EcoBreeze cooling system

The EcoBreeze cooling system is built according to a modular principle and consists of blocks with a cooling capacity of up to 50 kW, which can be combined into groups of up to four (200 kW) or eight (400 kW) modules.

Combining several modules into a system allows you to select the required cooling system for each specific case and avoid unnecessary costs.

Using EcoBreeze in conjunction with other energy-efficient components of the engineering infrastructure of the data center allows you to achieve values of the average annual PUE of the entire data center within 1.25—1.3. The possibility of combining the three methods of cooling allows us to obtain a coefficient of cooling that is unattainable for traditional cooling systems. When reducing the load on the cooling system, for example, when building a 2N fault-tolerant system, the effectiveness of this solution only increases due to the fact that natural cooling works almost year-round without connecting a compressor system.

EcoBreeze has many fundamental differences in comparison with the classic air conditioning systems used for data centers. The entire air conditioning system is brought out of the data center, and if previously cooling systems used perimetric air conditioners that supplied air under the raised floor or in-row cooling systems that were built in between the racks, this solution was still built into the data center room and occupied such a scarce free space . EcoBreeze is designed in such a way that all its elements are moved out of the main hall of the data center. The system can be installed on the ground, next to the data center or on the roof of a building, directly above the engine room. Another important feature of the EcoBreeze system is its modularity and support for scalability. If the customer has a growing load and it is necessary to increase the amount of “cold” produced, then the system allows you to add additional cooling modules, and no permutations are required in the machine room.

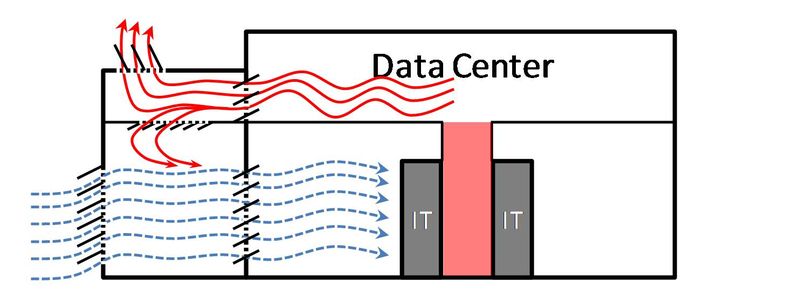

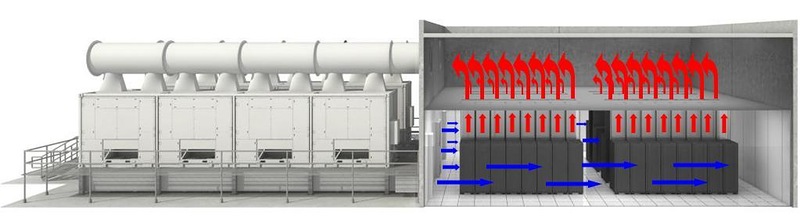

EcoBreeze cooling system air flow pattern with raised floor

When building a cooling system with a raised floor, the circulation of air flows is as follows: the hot air produced by the servers is limited to the Hot Aisle Containment System “hot” corridor (HACS, by the way, technology is patented by APC by Schneider Electric), then it rises to the ceiling and moves where it cools into the return pipe system EcoBreeze, after which it is fed back to the data center through the space under the raised floor in the “cold” corridor. Cold air is fed into the cold corridor and is used to keep the temperature safe for the servers to operate.

EcoBreeze cooling system air flow pattern without raised floor

The distribution pattern of air flow in a room without a raised floor looks a little different: hot air coming from the servers is limited by the “hot” corridor, then it rises to the ceiling and is fed to the EcoBreeze return pipe system. After cooling, the air is fed back into the machine room with the help of distributors located in the “cold” corridor.

Since the EcoBreeze cooling system is designed to work in cold climates, the manufacturer sees the main customers in the countries of northern Europe and Russia. Despite the fact that EcoBreeze shipments are scheduled for November — December 2011, already two large projects are in the process of design, one of which will be located in St. Petersburg. The harsh climate of the northern capital will be a good test of strength and resiliency.

Source: https://habr.com/ru/post/131246/

All Articles