An inside look: CD and HDD

Foreword

My previous article was devoted to the internal device of the chip from Nvidia , and, perhaps, to the internal device of any modern processor. In this article, we turn to the means of storing information, and I will tell you what are CD and HDD discs at the micro level.

CD

Let's start with the CD. Our test subject is a simple Verbatim CD-R. A regular disc with recorded (or rather printed) information consists of 3 main layers. Layer A is a polycarbonate disk, which is responsible for several functions at once. The first is the base of the disc, which withstands enormous rotational speeds inside the drive.

')

So in general terms, you can imagine the structure of a CD [1]

The polycarbonate disk, as it turned out, is additionally coated with a special varnish, which protects the outer surface of the disk from light mechanical damage.

The lacquer layer is highlighted in red; polycarbonate "starts" under it.

Under a beam of an electron microscope, a layer of protective varnish does not feel very well.

The second is that it is on polycarbonate, in the literal sense of the word, that information from the matrix is printed - be it a film, music or a program. According to Vicki, the polycarbonate base is 1.2 mm thick and weighs only 15-20 grams [1].

Naturally, polycarbonate and varnish are transparent to laser radiation, therefore, the "printed" information for the laser must be made "visible", for which the surface is covered with a thin layer of aluminum (layer B). It should be noted that CD-ROMs with “printed” information, CD-R and CD-RW have minor differences. In the latter two cases, an intermediate layer is added between polycarbonate and aluminum, which can change its properties under the action of laser radiation of a certain wavelength, and empty tracks are printed on the polycarbonate. These can be either colorants in the case of CD-R (something similar to a photoresist) or metal alloys in the case of CD-RW. That is why rewritable discs are not recommended to be exposed to direct sunlight and overheating, which can also cause a change in optical properties.

Let's compare the disc and the aluminum layer cut off from it. It is seen that there are “grooves” (pitas) on polycarbonate, and on the contrary, on the aluminum layer, elevations that fully correspond to the grooves:

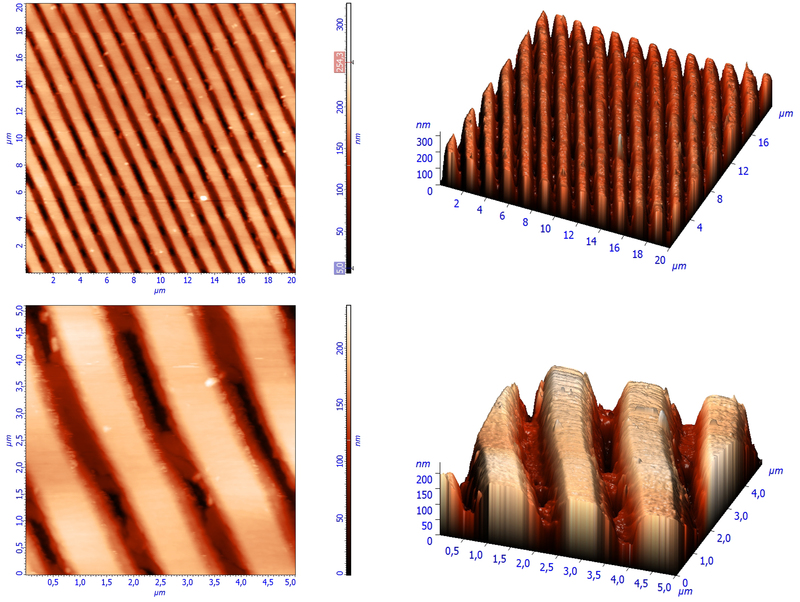

The usual grooves on the surface of polycarbonate (AFM image)

On the protective aluminum layer are visible pits, “vice versa”: not grooves, but protrusions (AFM image)

Next, the resulting “cake” is covered with a special protective layer C, whose main duty is to protect the “delicate” aluminum reflective layer. Then you can stick something on this layer, write with a marker, apply special additional layers for printing, etc. etc.

This video presents all the technological stages of CD production:

Recording on a CD like a record on a vinyl record, i.e. track with information goes in a spiral. It originates in the center of the disc and ends at the outer edge. But right in the middle of the disc, “empty” sections and tracks with recorded information “fit together”:

There was a record, but it was not. Comparison of empty tracks and tracks with recorded information (SEM micrographs)

There are no fundamental differences at the micro level of CDs from DVDs and, probably, Blu-Ray. Is that the pitas will be smaller. In our case, the dimensions 1 of the minimum groove are 330 nm in width and 680 nm in length, with the distance between the tracks ~ 930 nm.

NB If you have a scratched CD disc that cannot be read in any drive, try polishing it. For this fit almost any transparent polish. It will fill in the grooves that interfere with reading the information, and at least you can copy the information from the disk.

How can a layer of aluminum sometimes fancifully bend (almost a work of art — black and white):

Black and white stripes of our life. CD (SEM micrograph)

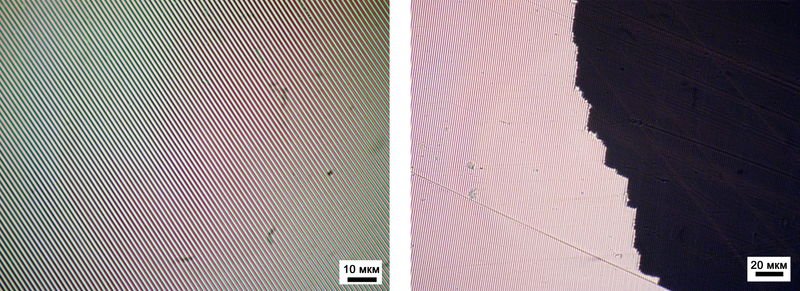

And finally, a couple of CD images taken with an optical microscope:

Optical microscopy: on the left - an aluminum reflecting layer, on the right - an Al layer (lighter area) on a polycarbonate disk (darker area)

HDD

Let us now proceed to the hard disk. For me, always, since the days of floppy disks and VHS, it has remained a mystery, how does the magnetic memory work? Before writing the article, I tried to find at least some video and media materials that would demonstrate, as in the previous video, the main stages of hard disk production, and was unpleasantly pleased with Vika: “Both plate surfaces, like a tape recorder, are covered with the finest dust of a ferromagnet - iron oxides, manganese and other metals. The exact composition and technology of deposition constitute a commercial secret ”[2]. It was necessary to reconcile and not seek truth from the HDD manufacturers (except that Seagate slightly opened its secrets), especially since with the advent of SSD the competition in the market became even stronger.

The plates themselves are made of non-magnetic metal alloys. The basis of these alloys are aluminum and magnesium, as the lightest construction materials. Then a thin magnetic layer is applied on them, again according to Wiki , 10–20 nm magnetic - then, perhaps, the word nanocrystalline would be appropriate - of the material, which is then covered with a small layer of carbon for protection. Since the disk is NoName, and it is made according to the ancient technology of parallel recording of information, I will allow myself to give here the composition of the material according to EDX ( X-ray microanalysis ): Co - 1.1 atomic%, Y - 1.53 at. %, Cr - 2.38 at. % Ni - 45.81 at. % The carbon content is 36.54%. From somewhere came Si and P, the content of which is 0.46 at. % and 12.25 at. %, respectively. The origin of silicon - apparently, in trace amounts remained on the surface after the work of the microtome and my polishing, and phosphorus - just stained the sample.

Honestly, I tried to find a layer of magnetic material with a thickness of "10-20 nm", but without success. If we proceed from what I saw, then the surface layer is about 12 micrometers thick:

The very “thin” layer that stores information in our hard drives

Of course, you can correct me in the comments, but:

1. the disk is quite old (i.e., the date of its manufacture dates back to the beginning of the last decade);

2. The features of the EDX are such that the depth of the signal output lies in the range from 1 to 10 μm;

Thus, it seems to me that these 12 micrometers are a magnetic layer, which is covered on top with a thin layer of carbon (50-100 nm), which may not be visible on the cut.

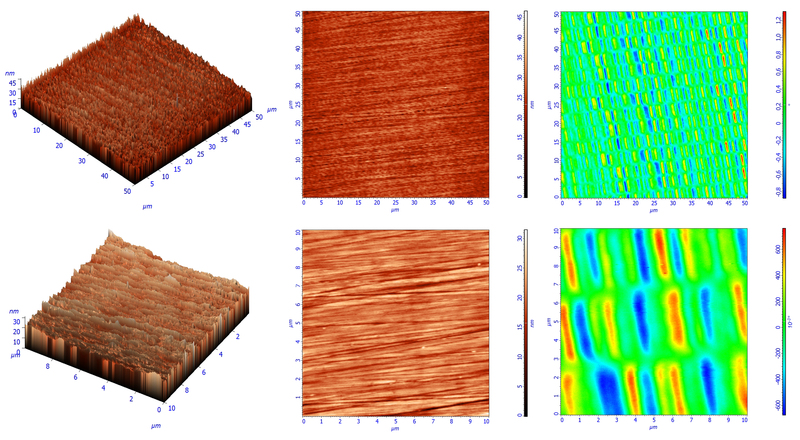

The very surface of the disk is very, very smooth, the height difference lies within 10 nm, which is comparable to the surface roughness of single-crystal silicon. And here are the images in phase contrast mode that correspond to the distribution of magnetic domains on the surface, i.e. we see actually separate bits of information:

AFM images of the surface of the hard disk. Images on the right are in phase contrast.

A little bit about phase contrast: first, the needle of an AFM microscope “gropes” the relief, then knowing the relief and repeating its shape the needle makes a second pass at a distance of 100 nm from the sample in order to “drown out” the action of van der Waals forces and “isolate” the action of magnetic forces A flash drive on how this happens can be viewed here .

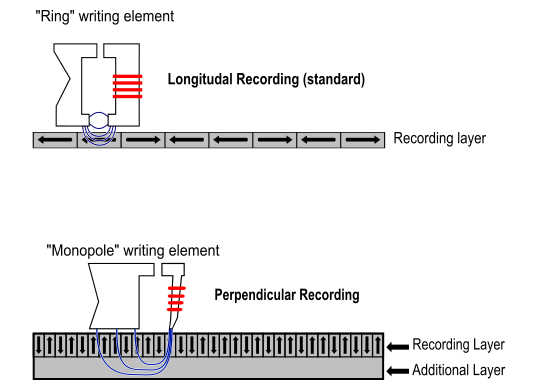

By the way, have we noticed that single magnetic domains are elongated along the disk plane and parallel to it ?! Beg a few words about the methods of recording. At the moment, disks with a perpendicular method of recording information (ie, those in which magnetic domains are oriented perpendicular to the plane of the disk), which appeared in 2005, almost completely supplanted disks with parallel recording. The advantage of perpendicular recording is obvious - the recording density is higher, but there is one subtle point in connection with the wiki data about the thickness of the magnetic layer. This nuance is called the superparamagnetic limit. Those. there is a certain critical particle size, after which the ferromagnet already at room temperature enters a paramagnetic state. Those. there is enough heat energy to turn and reorient such a small magnet. In the case of magnetic recording, they often act as follows: they make one of the “magnetic” sizes larger than the other two (this is clearly seen in the picture with the distribution of magnetic domains), then the magnetic moment is preserved in this larger direction. So, if in the case of parallel recording I can still believe that the magnetic layer is tens of nanometers with dimensions of 1 bit in several micrometers, then in the case of perpendicular recording, this simply cannot be. The thickness of such a magnetizable region with minimum dimensions in the plane of the disk, simply must be at least a few micrometers. So, perhaps, Vicky podviraet a little bit. Or they put a magnet in the form of nanoparticles with a diameter of 10-20 nm, and only then in some “clever” way they divide the disk into areas that are responsible for storing information. Unfortunately, I didn’t completely satisfy my curiosity and answered questions about magnetic information recording, maybe someone will help ?!

Comparison of parallel and perpendicular methods for recording information on hard disks [2]

I would also like to share three videos that were found on the Internet and are associated with hard drives. The first is dedicated to the principles of HDD work (How does it work?):

Maybe someone will like the video in English from Seagate:

The last is how the cost of 1 Mb HDD disk has changed since 1995 and how many discs have been released:

As promised, I post a video on how the survey was carried out on various devices (do not forget to read the description of the video on YouTube and leave your comments). For statistics: the shooting took 4 days (although everything could be put in 2), the duration of the video, which was subjected to installation - about 3 hours, the result was a 15-minute video. I hope that in the near future there will be English subtitles for this video.

PS: This article was published on the eve of the Science Festival, which will be held in Moscow from October 7 to 9, 2011 (really free access will be only on October 8 and 9), and I would like to invite everyone to visit our exhibition “The Beauty of Materials”, which will be held on the second floor of the Fundamental Library on the territory of Moscow State University.

PPS: With Anton Wojciechowski we are preparing several video notes on how some biological objects are arranged (a rose, for example, looks simply gorgeous). I think that they will not appear on Habré (agree that it is difficult to attach a microphotograph of a razor or a match head to IT), but as soon as the videos are ready, they will immediately appear on my channel on youtube and rutube, and always on Nanomet.ru website.

Sources:

1. Wiki: CD

2. Wiki: HDD

First , the full list of published articles on Habré:

Opening the Nvidia 8600M GT chip , a more detailed article is given here: Modern chips - a view from the inside

An inside look: CD and HDD

An inside look: LED bulbs

An inside look: the LED industry in Russia

An inside look: Flash and RAM

An inside view: the world around us

An inside look: LCD and E-Ink displays

An inside look: matrix digital cameras

An inside look: Plastic Logic

An inside look: RFID and other tags

An inside look: graduate school at EPFL. Part 1

An inside look: graduate school at EPFL. Part 2

An inside view: the world around us - 2

An inside view: the world around us - 3

An inside look: the world around us - 4

An inside look: 13 LED lamps and a bottle of rum. Part 1

An inside look: 13 LED lamps and a bottle of rum. Part 2

An inside look: 13 LED lamps and a bottle of rum. Part 3

An inside look: IKEA LED strikes back

An inside view: are Filament lamps good for you?

and 3DNews:

Microview: a comparison of modern smartphones displays

Secondly , in addition to the blog on HabraHabr , articles and videos can be read and viewed on Nanometer.ru , YouTube , and Dirty .

Thirdly , if you, dear reader, liked the article or you want to stimulate writing new ones, then act according to the following maxim: “pay what you want”

Yandex.Money 41001234893231

WebMoney (R296920395341 or Z333281944680)

Sometimes briefly, and sometimes not so much about the news of science and technology, you can read on my Telegram channel - welcome;)

Source: https://habr.com/ru/post/129893/

All Articles