Textile printer do it yourself - continued

Recently, I wrote here about a textile printer from, practically, improvised materials .

The point was to make sure that the idea was working, and it was possible. But this weekend I decided to finish the job, eliminate the identified jambs and bring the device as close as possible to the sold solutions. So, began with the manufacture of the frame.

It was decided to make of chipboard, because the material is quite strong, has sufficient rigidity and is quite simple in assembly-processing. Quickly figured the design, climbed into the Internet, found a chipboard cut closer to me, called, sent a list of parts, asked to cut it immediately, and after half an hour had passed, everything was in my house. budget - $ 25

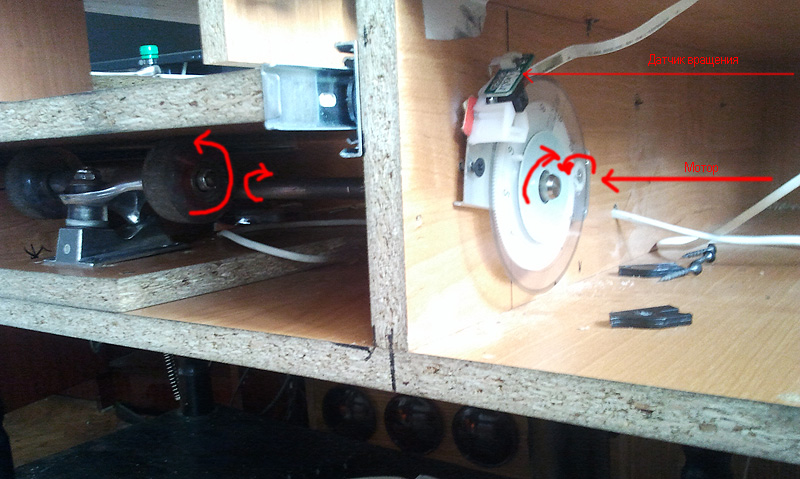

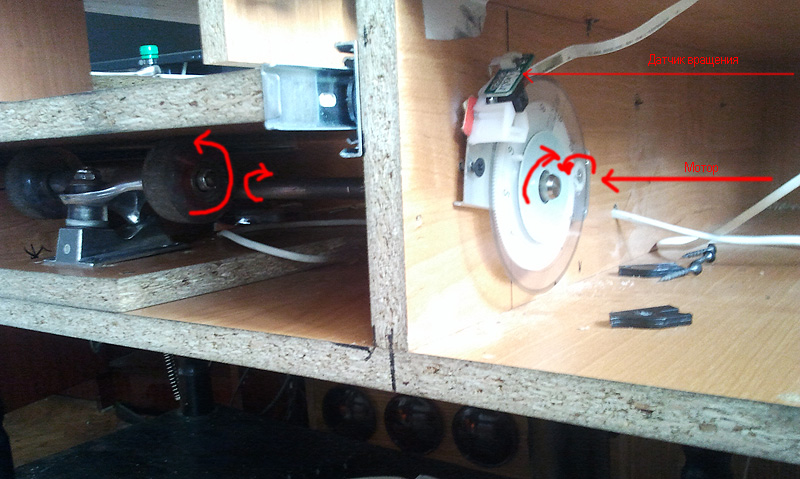

The second nuance was related to the problem of extension of the cable for the engine and the rotation sensor - they were on the opposite side of the board. Of course, it was possible to suffer with a soldering iron, but I decided to transfer everything to the side of the board - so now there were additional rollers between the paper feed shaft and the table (the shaft began to rotate in the opposite direction). The decision was spied on the bourgeois forums - and I must say it is very good. Let it look ridiculous, but the skate wheels are very well suited for this task. Quickly found a cheap used Chinese skate for $ 10.

')

In principle, these are all changes in the design. I collected everything and I was pleased with this option - no backlash, everything is clear and elegant.

The third nuance was associated with the printing of a white substrate. There are expensive commercial RIPs that allow you to fill in additional cartridges with white (for devices where, in addition to CMYK, additional colors are used - I have light blue and light crimson). But the expensive decision is at odds with the idea of doing everything as cheaply as possible. First of all I used all possible resources and torrents with pirated software - alas, I did not find the solution I needed. But I accidentally found information that you can configure a lot of things under Linux via gutenprint. I put Ubuntu for two nights, but something we didn’t manage to make friends with her - so she didn’t settle, cursing various errors. But digging through the forums I found a solution - winGP - allows you to print under Windows from the gimp through a guttenprint. Another sleepless night picking with its settings, a cartridge filled with wrong colors (filled yellow instead of light, what to see when what color prints) and now the settings are found — now the printer can print either in clean CMYK mode without using light or in light mode without using CMYK cartridges - so you can safely print both a white substrate and a picture on the same printer. Things are easy - tomorrow I will order white paints from Moscow and wait.

Well, here are a few photos - they understand the whole structure.

so now the rotation is transmitted through the wheels of the skateboard

the printer itself

here is the print quality

Well, to raise the mood - my cat, sniffing at 5 am while I mess with my monster

UPD

At the request of workers - the table drive system

And here two modules are clearly visible - it comes out of the printer - the printing part and the board are separate. Well, the drive, which is in the photo above. Everything. Here are three such pieces and nothing more tricky.

UPD: I started my blog, where I will share information as the printer is reworked. Who cares - go to printmod - the blog is dedicated to how to redesign printers for printing on textiles, and how to rework printers in general

UPD2: Continued: Printer for T-shirts: from home crafts to serial models of textile printer Edit

The point was to make sure that the idea was working, and it was possible. But this weekend I decided to finish the job, eliminate the identified jambs and bring the device as close as possible to the sold solutions. So, began with the manufacture of the frame.

It was decided to make of chipboard, because the material is quite strong, has sufficient rigidity and is quite simple in assembly-processing. Quickly figured the design, climbed into the Internet, found a chipboard cut closer to me, called, sent a list of parts, asked to cut it immediately, and after half an hour had passed, everything was in my house. budget - $ 25

The second nuance was related to the problem of extension of the cable for the engine and the rotation sensor - they were on the opposite side of the board. Of course, it was possible to suffer with a soldering iron, but I decided to transfer everything to the side of the board - so now there were additional rollers between the paper feed shaft and the table (the shaft began to rotate in the opposite direction). The decision was spied on the bourgeois forums - and I must say it is very good. Let it look ridiculous, but the skate wheels are very well suited for this task. Quickly found a cheap used Chinese skate for $ 10.

')

In principle, these are all changes in the design. I collected everything and I was pleased with this option - no backlash, everything is clear and elegant.

The third nuance was associated with the printing of a white substrate. There are expensive commercial RIPs that allow you to fill in additional cartridges with white (for devices where, in addition to CMYK, additional colors are used - I have light blue and light crimson). But the expensive decision is at odds with the idea of doing everything as cheaply as possible. First of all I used all possible resources and torrents with pirated software - alas, I did not find the solution I needed. But I accidentally found information that you can configure a lot of things under Linux via gutenprint. I put Ubuntu for two nights, but something we didn’t manage to make friends with her - so she didn’t settle, cursing various errors. But digging through the forums I found a solution - winGP - allows you to print under Windows from the gimp through a guttenprint. Another sleepless night picking with its settings, a cartridge filled with wrong colors (filled yellow instead of light, what to see when what color prints) and now the settings are found — now the printer can print either in clean CMYK mode without using light or in light mode without using CMYK cartridges - so you can safely print both a white substrate and a picture on the same printer. Things are easy - tomorrow I will order white paints from Moscow and wait.

Well, here are a few photos - they understand the whole structure.

so now the rotation is transmitted through the wheels of the skateboard

the printer itself

here is the print quality

Well, to raise the mood - my cat, sniffing at 5 am while I mess with my monster

UPD

At the request of workers - the table drive system

And here two modules are clearly visible - it comes out of the printer - the printing part and the board are separate. Well, the drive, which is in the photo above. Everything. Here are three such pieces and nothing more tricky.

UPD: I started my blog, where I will share information as the printer is reworked. Who cares - go to printmod - the blog is dedicated to how to redesign printers for printing on textiles, and how to rework printers in general

UPD2: Continued: Printer for T-shirts: from home crafts to serial models of textile printer Edit

Source: https://habr.com/ru/post/123813/

All Articles