Three-dimensional transistors. 22nm

Recently, Intel has made another breakthrough in processor design, and more precisely, in the evolution of transistors - the logical elements of modern processors. If the last 50 years in electronics, only planar structures have been used, then from now on in mass production the applied structure will become three-dimensional. The technology, which allowed to continue to follow Moore's law, was called Tri-Gate . In terms of significance, this step is comparable, perhaps, with the invention of the integrated circuit of transistors.

More recently, the processor could be represented as a sheet of paper, the performance of which depended on the number of transistor cells that fit in its area. The more transistors-cells on this sheet fit, the higher the performance was. It is clear that it is impossible to infinitely reduce the size of transistors - I even wrote a separate article about this, which “went well”. However, in the coming years, the semiconductor industry can breathe easy and continue the development at the same pace - now the cells can be “arranged” in several rows, that is, processor performance will grow deeper (well or up, as in the case of skyscrapers) and, frankly, I I wonder why they came to this point just now. However, they came up with something else back in 2002, but today it was a matter of mass implementation of technology.

')

Scientists have long recognized the advantages of 3D-structures - in the case of transistors, this approach will allow you to follow Moore's law for quite a long time. The essence of the new technology is obvious (the eye is armed):

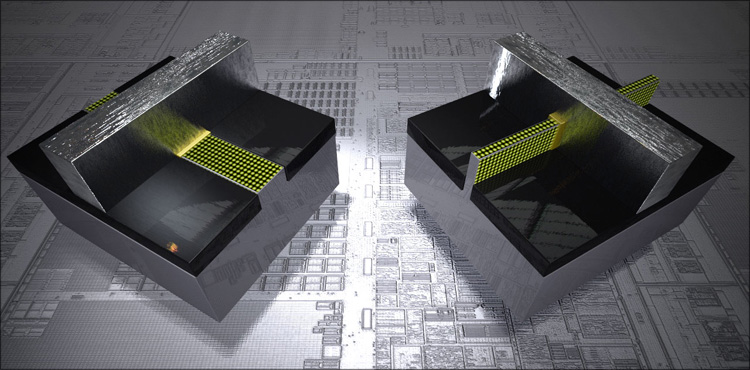

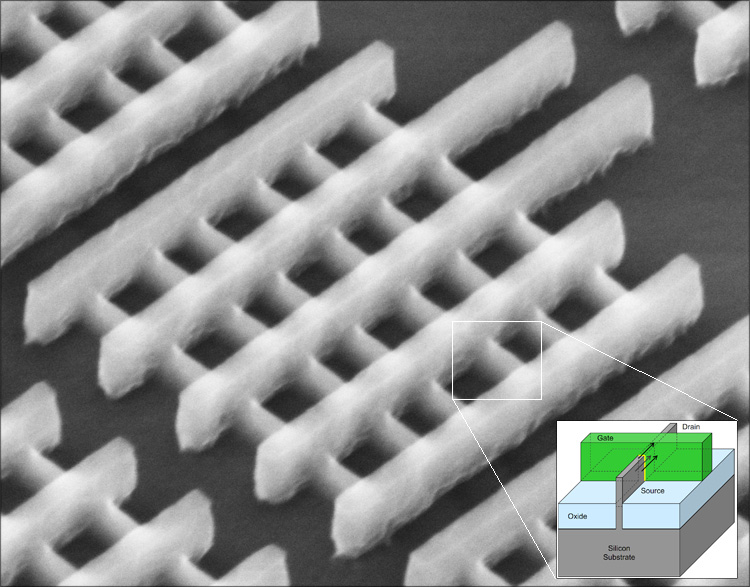

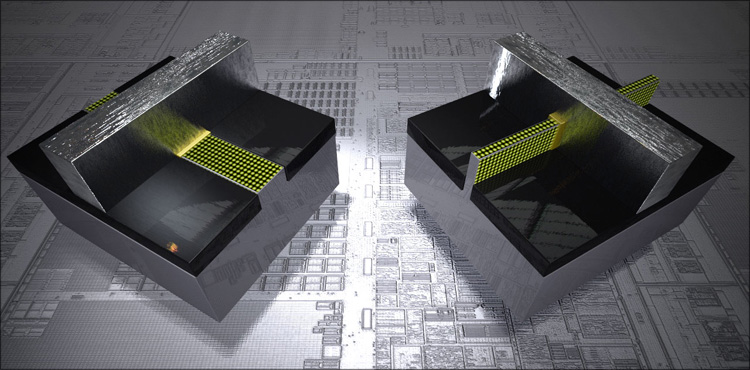

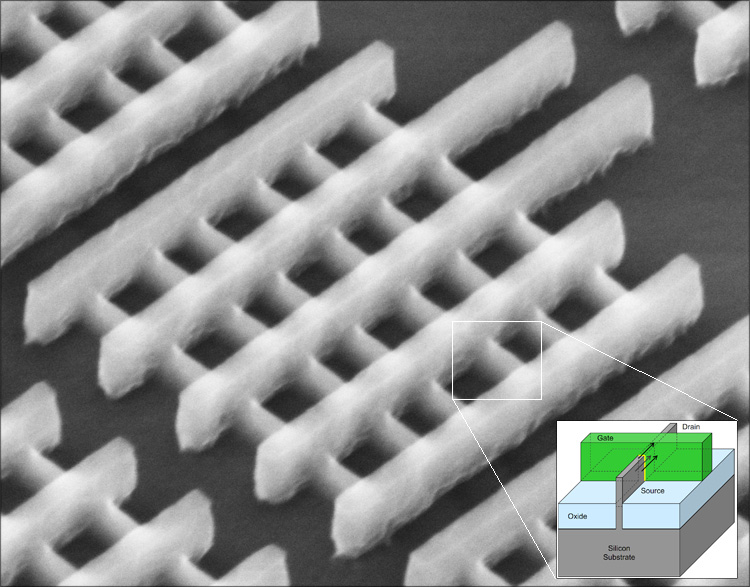

32 nm transistor

Tri-Gate 22nm Transistor

In the traditional planar structure of the transistor, the electric current can flow only along the narrow surface of the conductor under the gate. While in three-dimensional transistors, the current spreads in the thickness of the silicon ledge, "cutting through" the gate.

The result of this design decision is to reduce the resistance of the transistor in the open state, increase the resistance in the closed state and more quickly switch between these states. At the same time, it was possible to reduce the operating voltage and reduce leakage currents. As a result - a new level of energy efficiency and a solid performance increase in comparison with existing analogues.

The result of this design decision is to reduce the resistance of the transistor in the open state, increase the resistance in the closed state and more quickly switch between these states. At the same time, it was possible to reduce the operating voltage and reduce leakage currents. As a result - a new level of energy efficiency and a solid performance increase in comparison with existing analogues.

Tri-Gate transistors (manufactured using the 22nm technology) show an almost 40% performance boost compared to conventional (manufactured using the 32nm technology).

This is despite the fact that the new chips will consume almost half the energy (with the same performance) than their 32-nm brothers with a two-dimensional structure.

But you can do, for example, like this:

“ The invention of the Tri-Gate transistors and the introduction of new technology in 22-nm chips are changing the rules of the game, ” Paul Otellini , president of Intel, told me in secret. “In combination with materials with special dielectric constant, elements with metal gates, 3D transistors will help Intel significantly reduce energy consumption, cost of a chip per transistor and significantly increase productivity. Intel will continue to create the best products in the world in all areas - from mobile phones to supercomputers "

Mark Bohr, senior honorary researcher of the company: - A new invention not only allows you to continue to follow Moore's law. This is more than just a transition from one process to another - a new discovery allows you to design completely new devices.

The transition to the new three-dimensional transistors will be carried out together with the transition to a new 22-nanometer technology standard, reflecting the size of the structures of integrated circuits. The world's first microprocessor, manufactured at this rate, was a chip codenamed Ivy Bridge , designed primarily for desktop computers. Accordingly, Intel Core processors under this code name will be the first mass chips with Tri-Gate transistors - their mass mass production is scheduled to begin in late 2011. At least, in terms of technical equipment, almost everything is ready for this - after all, chips can be made on ordinary lithographic equipment.

As for mobile devices, this technology can also (and should) be adapted for them - perhaps this very step will begin to seriously strengthen the company's position in the pockets of users.

As a bonus:

Successes!

More recently, the processor could be represented as a sheet of paper, the performance of which depended on the number of transistor cells that fit in its area. The more transistors-cells on this sheet fit, the higher the performance was. It is clear that it is impossible to infinitely reduce the size of transistors - I even wrote a separate article about this, which “went well”. However, in the coming years, the semiconductor industry can breathe easy and continue the development at the same pace - now the cells can be “arranged” in several rows, that is, processor performance will grow deeper (well or up, as in the case of skyscrapers) and, frankly, I I wonder why they came to this point just now. However, they came up with something else back in 2002, but today it was a matter of mass implementation of technology.

')

Scientists have long recognized the advantages of 3D-structures - in the case of transistors, this approach will allow you to follow Moore's law for quite a long time. The essence of the new technology is obvious (the eye is armed):

32 nm transistor

Tri-Gate 22nm Transistor

In the traditional planar structure of the transistor, the electric current can flow only along the narrow surface of the conductor under the gate. While in three-dimensional transistors, the current spreads in the thickness of the silicon ledge, "cutting through" the gate.

The result of this design decision is to reduce the resistance of the transistor in the open state, increase the resistance in the closed state and more quickly switch between these states. At the same time, it was possible to reduce the operating voltage and reduce leakage currents. As a result - a new level of energy efficiency and a solid performance increase in comparison with existing analogues.

The result of this design decision is to reduce the resistance of the transistor in the open state, increase the resistance in the closed state and more quickly switch between these states. At the same time, it was possible to reduce the operating voltage and reduce leakage currents. As a result - a new level of energy efficiency and a solid performance increase in comparison with existing analogues.Tri-Gate transistors (manufactured using the 22nm technology) show an almost 40% performance boost compared to conventional (manufactured using the 32nm technology).

This is despite the fact that the new chips will consume almost half the energy (with the same performance) than their 32-nm brothers with a two-dimensional structure.

| 1 nm (nanometer) = one billionth meter (1/1 000 000 000m),% username% |

“ The invention of the Tri-Gate transistors and the introduction of new technology in 22-nm chips are changing the rules of the game, ” Paul Otellini , president of Intel, told me in secret. “In combination with materials with special dielectric constant, elements with metal gates, 3D transistors will help Intel significantly reduce energy consumption, cost of a chip per transistor and significantly increase productivity. Intel will continue to create the best products in the world in all areas - from mobile phones to supercomputers "

Mark Bohr, senior honorary researcher of the company: - A new invention not only allows you to continue to follow Moore's law. This is more than just a transition from one process to another - a new discovery allows you to design completely new devices.

The transition to the new three-dimensional transistors will be carried out together with the transition to a new 22-nanometer technology standard, reflecting the size of the structures of integrated circuits. The world's first microprocessor, manufactured at this rate, was a chip codenamed Ivy Bridge , designed primarily for desktop computers. Accordingly, Intel Core processors under this code name will be the first mass chips with Tri-Gate transistors - their mass mass production is scheduled to begin in late 2011. At least, in terms of technical equipment, almost everything is ready for this - after all, chips can be made on ordinary lithographic equipment.

As for mobile devices, this technology can also (and should) be adapted for them - perhaps this very step will begin to seriously strengthen the company's position in the pockets of users.

As a bonus:

Successes!

Source: https://habr.com/ru/post/118816/

All Articles