All about Lasers

You all love lasers. I know something, I trudge from them more than yours. And if someone doesn’t like it, he simply didn’t see the dance of sparkling dust particles or how a blinding tiny light gnaws plywood

You all love lasers. I know something, I trudge from them more than yours. And if someone doesn’t like it, he simply didn’t see the dance of sparkling dust particles or how a blinding tiny light gnaws plywood

It all started with an article from the Junior technician for the 91st year about creating a laser for dyes - then it was simply impossible to repeat the design for a simple student ... Now, fortunately with lasers, the situation is simpler - you can get them from the broken technology, you can buy them ready, it is possible to assemble from parts ... About the lasers closest to reality and we are talking today, as well as methods of their use. But first of all about safety and danger.

Why lasers are dangerous

The problem is that the parallel laser beam is focused by the eye to a point on the retina. And if it takes 200 degrees to light the paper, only 50 are enough to damage the retina so that the blood coagulates. You can hit the blood vessel with a point and block it, you can get into a blind spot, where nerves from all eyes go to the brain, you can burn out the line of "pixels" ... And then the damaged retina can begin to exfoliate, and this is the way to a complete and irreversible loss view. And the most unpleasant thing is that you don’t notice any damage at the beginning: there are no pain receptors, the brain builds up objects in damaged areas (so-called reminding of broken pixels), and only when the damaged area becomes large enough can you notice that the objects disappear when it hits . You will not see any black areas in sight - just in some places there will be nothing, but this is not noticeable. Only an ophthalmologist can see damage in the early stages.

The danger of lasers is considered on the basis of whether it can cause damage before the eye blinks reflexively - and a power of 5mW for visible radiation is considered not too dangerous. Because infrared lasers are extremely dangerous (well, and partly violet - they are just very poorly visible) - you can get damaged and never see that the laser is shining right in your eye.

')

Therefore, I repeat, it is better to avoid lasers that are more powerful than 5mW and any infrared lasers.

Also, never, under any circumstances, look “at the exit” of the laser. If it seems to you that “something is not working” or “somehow weakly” - look through the webcam / soap box (but not through a DSLR!). It also allows you to see infrared radiation.

Of course there are goggles, but there are many subtleties. For example, on the DX website there are glasses against the green laser, but they transmit infrared radiation — and vice versa increase the danger. So be careful.

Ps. Well, of course, I distinguished myself once - inadvertently seated my beard with a laser ;-)

650nm - red

This is probably the most common type of laser on the Internet, and all because every DVD-RW has one, with a capacity of 150-250mW (the higher the recording speed, the higher). At 650nm, the sensitivity of the eye is not very, therefore, although the dot is dazzlingly bright at 100-200mW, the beam is only barely visible during the day (at night you can see better of course). Starting from 20-50mW, such a laser begins to "burn" - but only if it is possible to change its focus in order to focus the spot on a tiny dot. At 200 mW, it burns very quickly, but again, the focus is needed. Balls, cardboard, gray paper ...

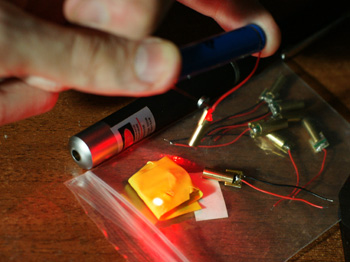

You can buy them ready ( for example, such on the first photo is red ). They also sell small lazeriki "wholesale" - real babies, although they all have an adult - power system, custom focus - what is needed for robots, automation.

You can buy them ready ( for example, such on the first photo is red ). They also sell small lazeriki "wholesale" - real babies, although they all have an adult - power system, custom focus - what is needed for robots, automation.And most importantly - such lasers can be carefully taken out of DVD-RW (but remember that there is still an infrared diode there, you need to be very careful with it, see below). (By the way, non-warranty DVD-RWs are in heaps in service centers - I carried 20 pieces to myself, there was no more information). Laser diodes very quickly die from overheating, from exceeding the maximum luminous flux - instantly. Exceeding the rated current by half (assuming no luminous flux is exceeded) shortens the service life by 100-1000 times (so be careful with “overclocking”).

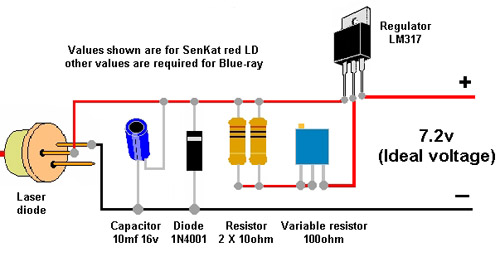

Power: there are 3 basic circuits: the most primitive, with a resistor, with a current stabilizer (on LM317, 1117), and the highest aerobatics - using feedback through a photodiode.

In normal factory laser pointers, the 3rd scheme is usually used - it gives the maximum stability of the output power and the maximum lifetime of the diode.

The second scheme is simple to implement, and provides good stability, especially if you leave a small power margin (~ 10-30%). That is what I would recommend to do - the linear stabilizer is one of the most popular parts, and in any, even the smallest radio shop, there are analogues of LM317 or 1117.

The second scheme is simple to implement, and provides good stability, especially if you leave a small power margin (~ 10-30%). That is what I would recommend to do - the linear stabilizer is one of the most popular parts, and in any, even the smallest radio shop, there are analogues of LM317 or 1117.The simplest circuit with a resistor described in the previous article is only slightly easier, but with it the diode is simply killed. The fact is that in this case the current / power through the laser diode will depend strongly on the temperature. If, for example, at 20C you get a current of 50mA and the diode does not burn, and then the diode heats up to 80C during operation, the current will increase (they are such cunning, these semiconductors), and having reached, say, 120mA, the diode begins to shine with only black light. Those. such a scheme can still be used if you leave at least three to four times the power margin.

And lastly, debug the circuit stands with the usual red LED, and solder the laser diode at the very end. Cooling required! Diode "on the wires" will burn instantly! Also, do not wipe or touch the laser optics (at least> 5mW) - any damage will “burn out”, so blow it with a pear if necessary and that's it.

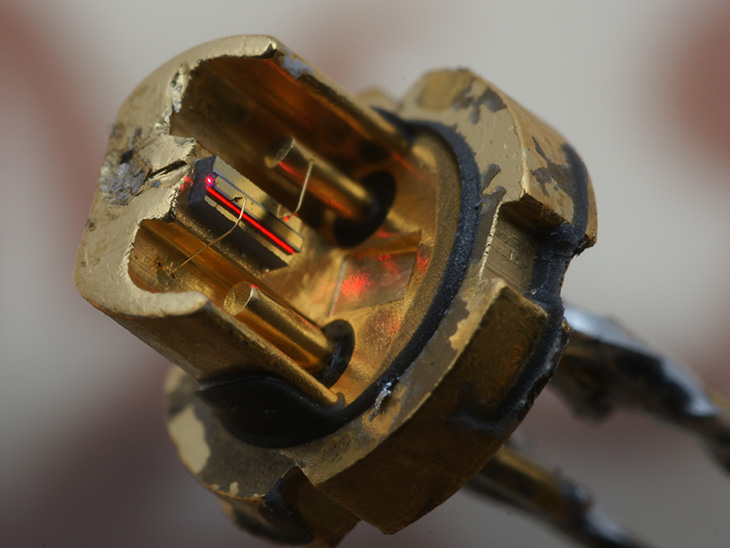

And here is what a laser diode looks like at work. By dents can see how close I was to failure, taking it out of the plastic mount. This photo also was not easy for me

532nm - green

They are difficult to set up - these are the so-called DPSS lasers: The first laser, infrared at 808nm, shines into a Nd: YVO4 crystal - laser radiation is generated at 1064nm. It hits the crystal "frequency doubler" - the so-called. KTP, and we get 532nm. It’s not easy to grow all these crystals, because for a long time DPSS lasers were damn expensive. But thanks to the shock work of the Chinese comrades, they are now fully available - from $ 7 a piece. In any case, mechanically it is a complex device, afraid of falls, sudden changes in temperature. Be careful.

The main plus of green lasers - 532 nm is very close to the maximum sensitivity of the eye, and both the point and the beam itself are very clearly visible. I would say that a 5mW green laser shines brighter than 200mW red (in the first photo just 5mW green, 200mW red and 200mW violet). Therefore, I would not recommend buying a green laser more powerful than 5mW: I bought the first green at 150mW and this is real tin - nothing can be done with it without glasses, even the reflected light blinds and leaves unpleasant sensations.

The main plus of green lasers - 532 nm is very close to the maximum sensitivity of the eye, and both the point and the beam itself are very clearly visible. I would say that a 5mW green laser shines brighter than 200mW red (in the first photo just 5mW green, 200mW red and 200mW violet). Therefore, I would not recommend buying a green laser more powerful than 5mW: I bought the first green at 150mW and this is real tin - nothing can be done with it without glasses, even the reflected light blinds and leaves unpleasant sensations.Also, green lasers have a big danger: 808 and especially 1064nm infrared radiation comes from the laser, and in most cases it is more than green. Some lasers have an infrared filter, but most green lasers under $ 100 do not. Those. The laser's “damaging” ability to the eye is much more than it seems - and this is another reason for not buying a green laser that is more powerful than 5 mW.

Of course, it is possible to burn green lasers, but again, the power from 50mW + is needed if the side infrared beam “helps” close, then it will quickly become “out of focus” with distance. And considering how blind he is, nothing fun will come of it.

405nm - purple

This is rather a near ultraviolet. Most diodes - emit 405nm directly. The problem with them is that the eye has a sensitivity at 405nm about 0.01%, i.e. The 200mW laser spot seems to be deadly, but in reality it is damn dangerous and dazzlingly bright - the retina affects all 200mW. Another problem is that the human eye is accustomed to focusing "under the green" light, and the 405nm spot will always be out of focus - not a very pleasant feeling. But there is a good side - many objects fluoresce, for example, paper - with bright blue light, only this saves these lasers from being forgotten by the mass public. But then again, not so much fun with them. Although 200mW harness be healthy, because of the difficulty of focusing the laser to the point it is more difficult than with red. Also, photoresists are sensitive to 405nm, and those who work with them can figure out why this might be needed ;-)

780nm - infrared

Such lasers in CD-RW and as the second diode in DVD-RW. The problem is that the human eye does not see the beam, and therefore such lasers are very dangerous. You can burn your retina and not notice it. The only way to work with them is to use a camera without an infrared filter (for example, in web cameras it is easy to get it), then the beam and the spot will be visible. IR lasers can probably be used only in self-made laser “machine tools”, I would not recommend to indulge with them.

Also, IR lasers are in laser printers along with a scanning pattern - 4 or 6 graded rotating mirror + optics.

10 micron - infrared, CO2

This is the most popular type of laser in the industry. Its main advantages are low price (tubes from $ 100-200), high power (100W - routine), high efficiency. They cut metal, plywood. Engrave and so on. If you want to make a laser machine yourself, then in China ( alibaba.com ) you can buy ready-made tubes of the necessary power and assemble only the cooling and power supply system for them. However, special craftsmen also make tubes at home, although it is very difficult (the problem in mirrors and optics is that 10mm glass does not let the radiation through - only optics made of silicon, germanium and some salts are suitable here).

Lasers applications

Mostly they are used in presentations, they play with cats / dogs (5mW, green / red), astronomers point out constellations (green 5mW and above). Self-made machines - work from 200mW on thin black surfaces. CO2 lasers cut almost anything. That's just hard to cut a printed circuit board - copper reflects radiation very well longer than 350nm (therefore, in production, if you really want to - use expensive 355nm DPSS lasers). Well, the standard entertainment on YouTube - bursting balls, cutting paper and cardboard - any lasers from 20-50mW, provided the possibility of focusing to a point.

From the more serious - target indicators for weapons (green), you can make holograms at home (semiconductor lasers are more than enough for this), you can print 3D-objects from UV-sensitive plastic, you can expose the photoresist without a template, you can shine a corner reflector on the moon , and after 3 seconds to see the answer, you can build a 10Mbit laser communication line ... There is no limit to the scope for creativity

So, if you still think, to buy a laser - take 5mW green :-) (well, 200mW red if you want to burn)

Questions / opinions / comments - in the studio!

Source: https://habr.com/ru/post/117008/

All Articles