Inventory management for small online stores

The issue of inventory management of a commercial enterprise is one of the basic ones for increasing the efficiency of its work. Usually this term is associated with complex analytical models, which are part of a large computer enterprise management system (ERP). It is easy to imagine abstruse analysts working with gigabytes of accumulated statistics with some distant goal “to increase efficiency”.

In fact, it is. But this is not the whole truth.

First you need to realize that the difficulty in this matter depends on the theoretical preparation of the person who wants to engage in the analysis. On the other hand, for small trade enterprises a complex model is not needed, and the basic concepts of the simplified model can be easily explained “on the fingers”. Then we will speak about such a simple and easy to understand analytical model.

The analytical system, which we will discuss further, was developed as an additional inventory management module for a small online store. For her work, statistical calculations are used - that is, the accumulated information on sales should be sufficient for statistically correct conclusions. You can recommend using this model with sales information for at least 10-15 periods between orders.

')

Efficient inventory management

What does “efficiency” mean in inventory management? What state of affairs will be considered ideally effective?

Answer this question like this. In the process of transferring goods from the manufacturer through the store to the buyer, the ideal case is when the store mark-up for the goods remains in the store, and the goods do not fall into the store’s warehouse at all - immediately transported to the buyer. As they say, "trade from the wheels." A viable option.

However, in ordinary business this rarely happens. Here, for example, possible problems:

- The manufacturer sells goods only in bulk. To come for each unit of the ordered goods will not work.

- The manufacturer requires an advance payment for the goods received. It is necessary to take a prepayment from the buyer, after which it is risky to quickly get the goods from the manufacturer.

- Delivery of goods from the manufacturer is difficult and time-consuming (through customs, for example). Most often, the buyer wants to pay money and get the goods now. He will not wait.

- Seasonal demand. At the peak of the season, the manufacturer cannot cope with deliveries and there is simply nothing to trade.

- Etc.

Therefore, the effectiveness in our case is the balance between the funds frozen in the form of goods and the speed of their delivery to the buyer . Few goods are in stock (and there is free money) - with a sharp increase in demand there will be nothing to trade with. As time goes on, no profit is earned, and money starts to flow through overhead (salary, rent, communications, etc.). A lot of goods in stock (and there is no free money) - the demand may change, the goods become outdated, and the store will not be able to earn money for it in the right amount.

The most convenient and effective way to work in such a situation is to individually calculate the necessary volumes and costs depending on the type of goods. In our case, we use a method called "ABC-XYZ analysis".

ABC-XYZ analysis

This method assumes that all products presented in the store will be divided (independently) into ABC and XYZ groups according to certain criteria. For division into groups are used:

- The contribution of each product in the total amount of sales for all time

- The average number of sales of each product for each period between orders

- Deviation from the average number of sales in each of the periods

The division into groups A, B and C is based on the contribution of the product to total sales. It is based on "Pritzip Pareto" - 80% of the amount of sales is due to 20% of the goods. Accordingly, products of group A are items that gave 80% of the contribution to total sales. For group B - another 15%, for group C - the rest.

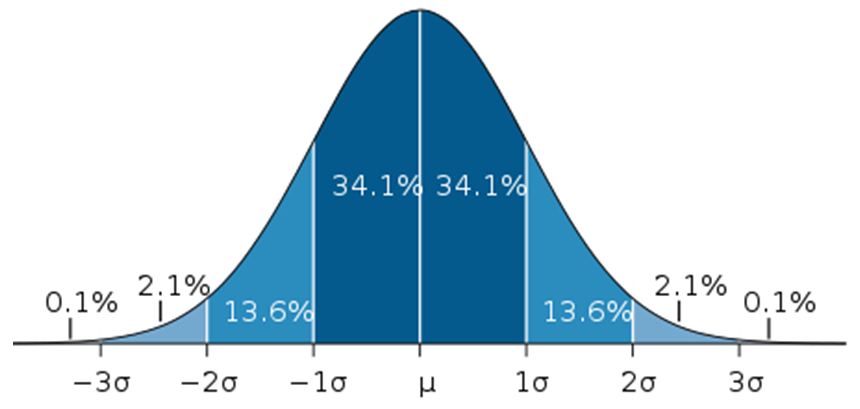

The division into groups X, Y and Z allows the classification of goods depending on the nature of their consumption and the accuracy of forecasting changes in their needs. For analysis, the concept of variation coefficient is used, which shows what proportion of the average value of this value (arithmetic mean) is its mean spread (average deviation from arithmetic mean). The smaller the value of the coefficient of variation, the more accurately you can predict the value.

- Group X - products are characterized by a stable amount of consumption, minor fluctuations in their consumption and high accuracy of the forecast.

- Group Y - products are characterized by well-known trends in determining the need for them (for example, seasonal fluctuations) and average forecasting capabilities.

- Group Z - resource consumption is irregular, there are no trends, forecasting accuracy is low.

Goods groups AX and BX are characterized by high turnover and stability. It is necessary to ensure their constant availability, but for this it is not necessary to create an excess safety stock. Consumption of goods of these groups is stable and well predicted. Products of the AY and BY groups with high turnover have insufficient flow stability, and, as a result, to ensure constant availability, it is necessary to increase the safety stock.

Products of AZ and BZ groups with high turnover are characterized by low predictability of consumption. Attempting to ensure the guaranteed availability of all the goods of these groups only due to excess insurance inventory will lead to the fact that the company's average inventory increases significantly. For these groups, the ordering system should be reviewed.

For products of the CX group, you can use the system of orders with constant frequency and reduce the insurance inventory. For goods of the CY group, you can use the order system with a constant amount (volume) of the order, but at the same time to form an insurance stock, based on the company's available financial capabilities. The CZ product group includes all new products, non-constant demand products supplied under the order, etc. Some of them can be safely withdrawn from the range, and the other part must be regularly monitored, since it is from the products of this group that illiquid or difficult-to-implement stocks arise due to which the company incurs losses.

Goods groups A and B constitute the main commodity turnover of the company. Therefore, it is necessary to ensure their continued availability. Usually, an excess safety stock is created for the products of group A , and sufficient for the goods of group B. Using XYZ analysis allows you to develop a more accurate assortment policy and due to this reduce the total inventory.

In the inventory management module, group boundaries can be changed. The description of the model is given by source .

Non-performing stocks

Non-performing stocks are goods that have not been selling for a long time or have more than needed stocks. Usually this class includes goods that have not had any sales in the past six months, or whose stocks correspond to more than twelve months of sales (based on average sales data per month and their statistical deviation) - little-used stocks and few -wrapable stocks .

In the module of inventory management the period can be changed - week, month, quarter, year.

Service level

After the division of goods into groups, a goal is set that corresponds to efficient inventory management. In our case, let's call this goal “ Service Level ” - the probability that the product will be in stock when demand for it occurs; probability of working without shortage.

In the inventory management module, the target service level can be set individually for each of the nine groups received. The total inventory management performance indicator is calculated - the average service level for the store , and the average service levels for each of the groups. In the reports, you can specify the level of service up to each item.

Order planning

The result of each inventory management cycle will be an order (list of products and their quantity), which will allow to bring the level of service for each product to the target value.

In the module of inventory management the order is formed in this way.

1. STEP 1

- The sizes of the ABC and XYZ groups and the service level targets for each group are set.

- Sets the frequency of orders (the value of the period between orders) and the forecast of sales growth for the next period.

- Sales statistics are calculated.

2. STEP 2

- Parameters are selected for the goods for which the next order will be placed:

- It is decided whether to consider non - performing stocks for an order.

- Information about the next order is formed - a list of products, data on their groups and sales statistics and the quantity for the next order.

disadvantages

As already mentioned, a simplified inventory management model for small trading companies is described here. What is simplified in it?

- No account of goods in transit.

- It is assumed that orders are made once per period.

- There is no individual sales forecast for each product.

- Planning is made on the basis of data on previous sales, taking into account the overall growth or decrease in demand for the entire range.

There is where to grow if necessary.

Source: https://habr.com/ru/post/115386/

All Articles