Office equipment inventory

Good day.

Not so long ago, changed jobs. As they say came and was horrified. In connection with the recent relocation of this company to a new office, the entire server room was an eerie spectacle — the prying up of boxes and packages with kits and devices. Semi-assembled system units and monitors from small to large. Also I was saddened by the absence of any information about the number and characteristics of devices in the whole company.

Well, actually it was not a big digression.

Task.

Make an inventory.

Solutions:

Option 1 - Automatic script for collecting configuration / information from each computer in the network. (he unfortunately dropped immediately, because the network is very heterogeneous)

Option 2 - Manually rewrite all equipment. (not the most convenient option, but there was no other)

')

The hardest thing to start, but the eyes are afraid, and the hands do.

We analyze all the points.

1. Since time is usually limited and everything had to be done yesterday, I decided to use the Ms Excel spreadsheet.

I decided that the inventory number of the device will be composed of two parts (DEV-TYPE + ID)

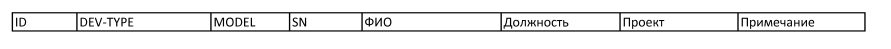

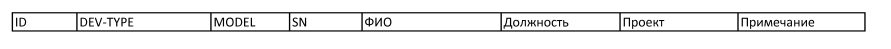

Here is an approximate table cap (with your variations naturally)

The points

ID - unique serial number of the device (I took 4-digit numbers) starting from 0001

DEV-TYPE - device type (MON, PC, NB, SRV, NET, OTHER, PRINT) according to your wishes.

MODEL - device model

SN-serial number

Name - for whom this device is assigned

Position, Project, Note (this is rather optional)

2. To facilitate this process can only be delegated part of the task to end users, not forgetting about the control process. What was actually done - the most active / clever was explained how to find out the configuration of his PC (in the case of a laptop / monitor / printer where the model and serial number). Next, this inventory form was uploaded to the shared folder, and it remained to wait until the shared folder was filled with already filled tables from users. Of course, it didn’t go away without errors, we had to approach and check it because it was confusing where the serial was, and where the model was, but still it saved a lot of time.

3. Help us to identify the devices should barcodes or their analogs stickers. I chose the stickers on the basis that this solution would be less expensive and less time consuming (here I unfortunately lost it, because we all know that the cheaper the device, the less functions it has).

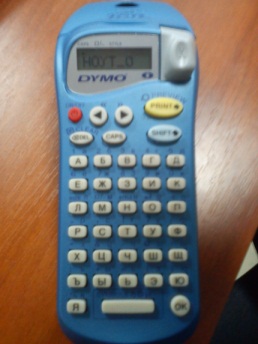

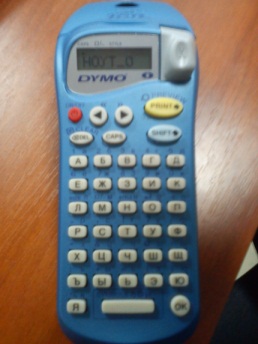

The DYMO Letra Tag + pair of cassettes was purchased (it is better to take paper tapes - plastic ones tend to peel off over time).

From the advantages it can be noted that it is quite portable and intuitive to manage.

Of the minuses - the lack of the English layout, there is no possibility of automatic numbering of stickers.

that's how he looks

cassette is inserted

! 6! AA batteries - printed about 3000 stickers (should be enough for the same amount)

here is an example of a finished sticker

As a result, we have already prepared a table with information provided by users + collected by us, it remains only to number the equipment. Next, print your list and stickers to them. I printed the stickers in two rows. Top DEV-TYPE Bottom of his ID. After that, a rather laborious process of pasting and deleting from the list of already pasted devices.

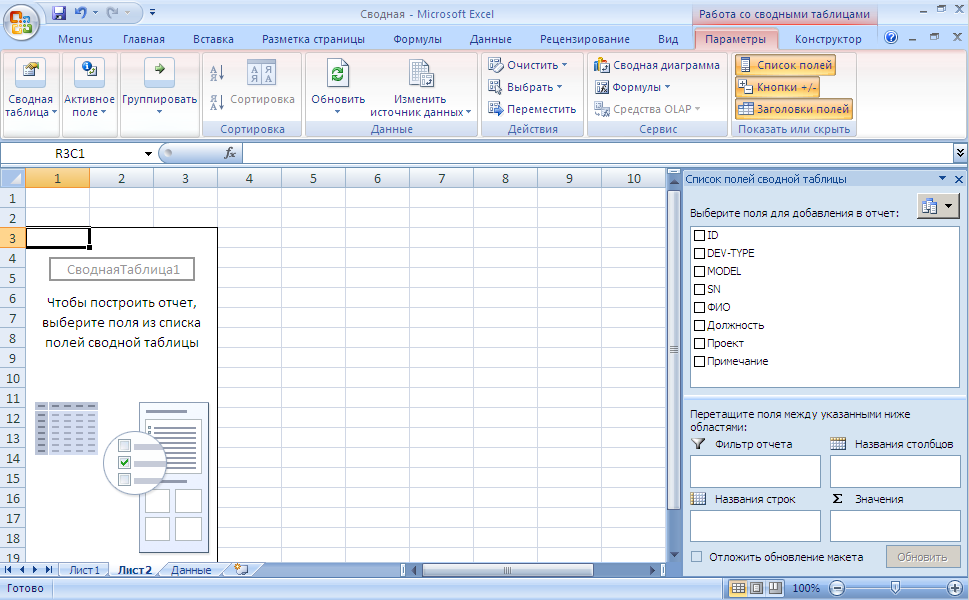

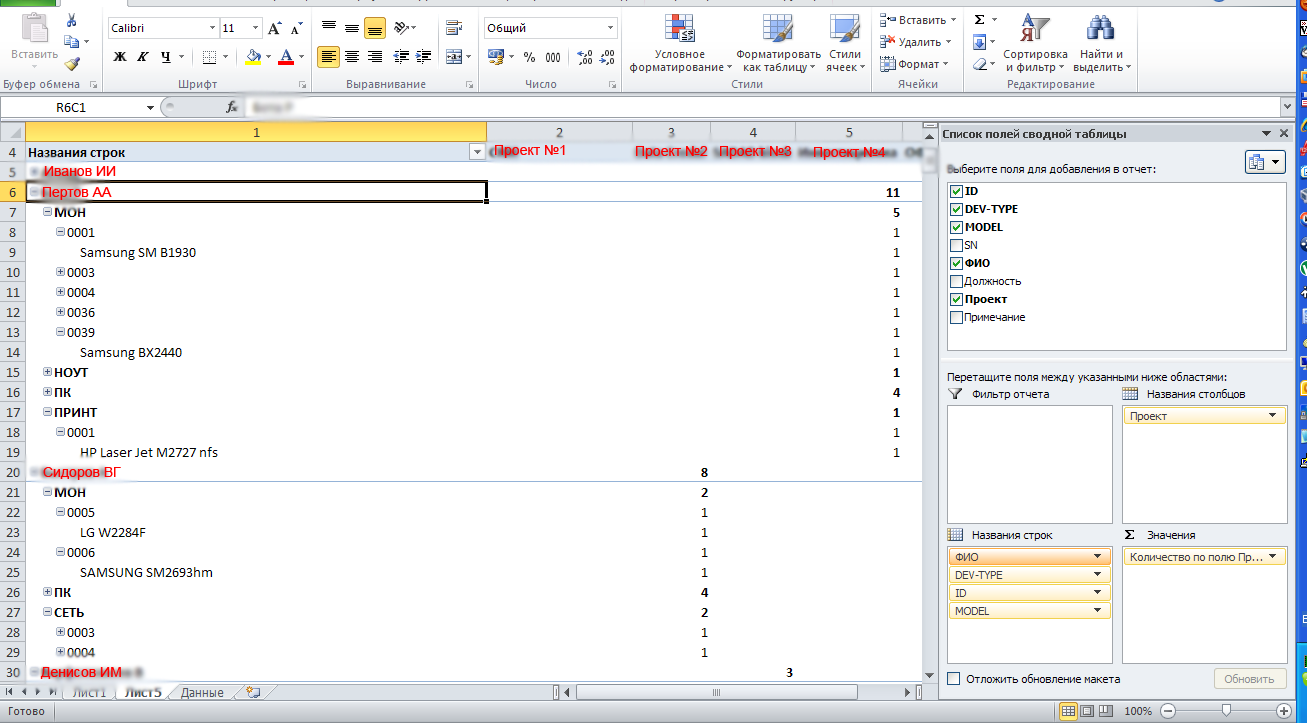

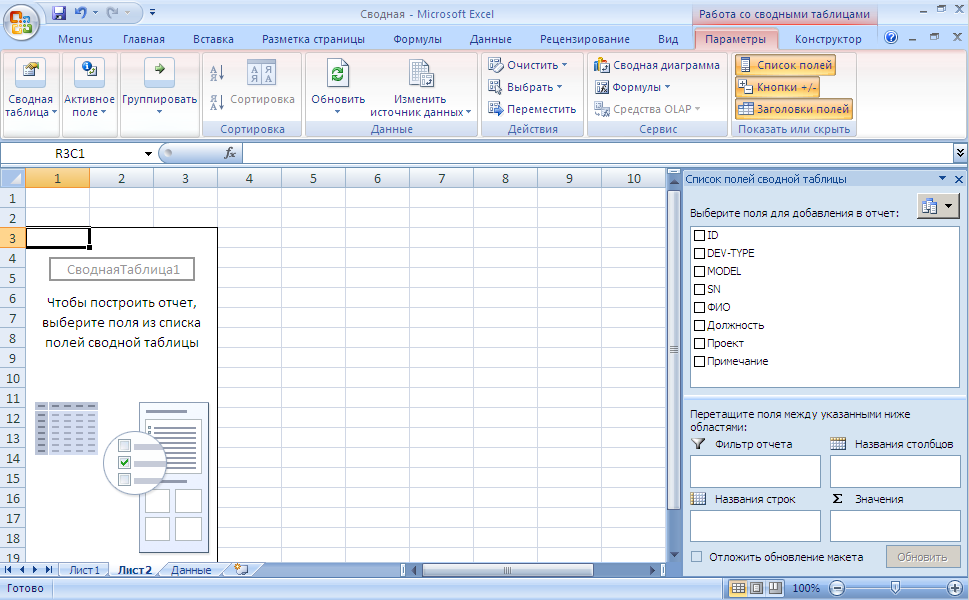

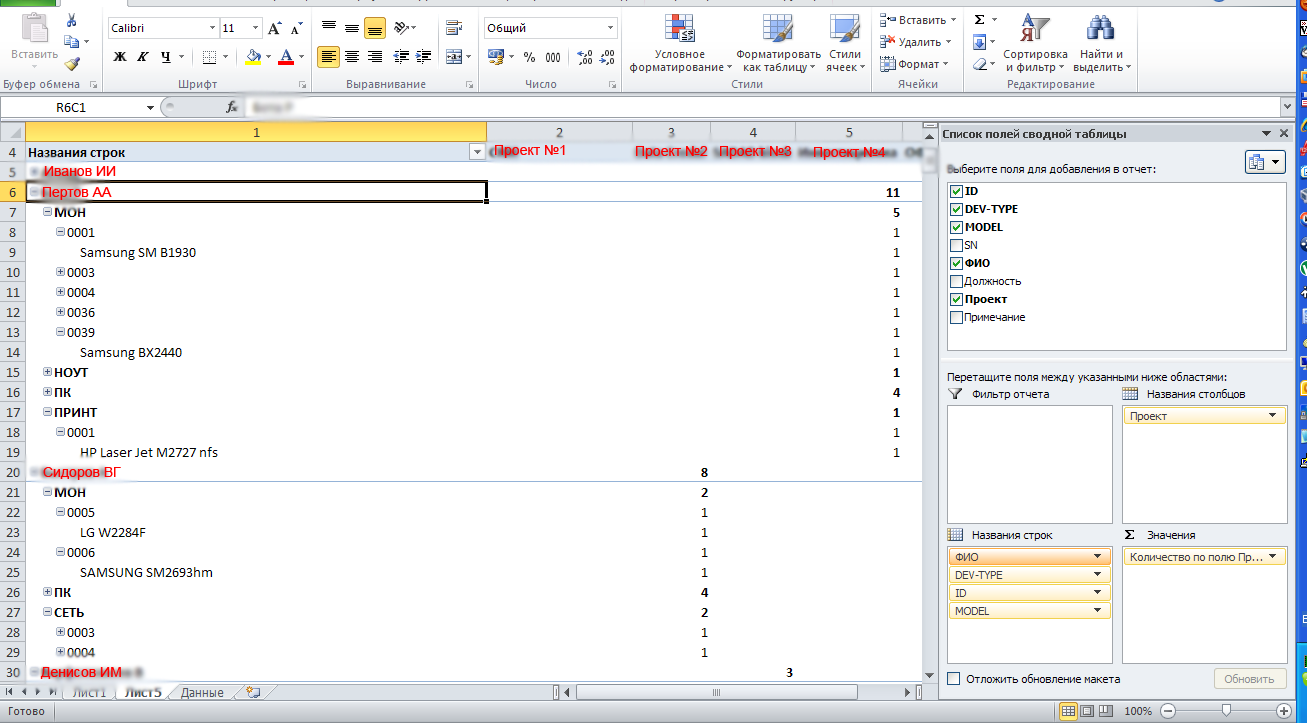

It is also necessary to create a pivot table, since It is not very convenient to read a table of 200-300 positions for all devices. With this we can use the function already built into Excel. Insert -> Pivot Table.

The following is an example of how to create a simple summary table, with the output of information on the number of equipment on projects

A small nuance, when adding new equipment, the pivot table needs to be re-created.

findings

Ps. I apologize in advance for the quality of the photos (phone camera).

Pss. I'm not sure that I picked the blog correctly. Where to transfer advise?

Not so long ago, changed jobs. As they say came and was horrified. In connection with the recent relocation of this company to a new office, the entire server room was an eerie spectacle — the prying up of boxes and packages with kits and devices. Semi-assembled system units and monitors from small to large. Also I was saddened by the absence of any information about the number and characteristics of devices in the whole company.

Well, actually it was not a big digression.

Task.

Make an inventory.

Solutions:

Option 1 - Automatic script for collecting configuration / information from each computer in the network. (he unfortunately dropped immediately, because the network is very heterogeneous)

Option 2 - Manually rewrite all equipment. (not the most convenient option, but there was no other)

')

The hardest thing to start, but the eyes are afraid, and the hands do.

We analyze all the points.

- it is necessary to decide where and in what form we will enter information.

- how this process can be facilitated.

- how to identify these devices (who is the owner, etc., etc.)

1. Since time is usually limited and everything had to be done yesterday, I decided to use the Ms Excel spreadsheet.

I decided that the inventory number of the device will be composed of two parts (DEV-TYPE + ID)

Here is an approximate table cap (with your variations naturally)

The points

ID - unique serial number of the device (I took 4-digit numbers) starting from 0001

DEV-TYPE - device type (MON, PC, NB, SRV, NET, OTHER, PRINT) according to your wishes.

MODEL - device model

SN-serial number

Name - for whom this device is assigned

Position, Project, Note (this is rather optional)

2. To facilitate this process can only be delegated part of the task to end users, not forgetting about the control process. What was actually done - the most active / clever was explained how to find out the configuration of his PC (in the case of a laptop / monitor / printer where the model and serial number). Next, this inventory form was uploaded to the shared folder, and it remained to wait until the shared folder was filled with already filled tables from users. Of course, it didn’t go away without errors, we had to approach and check it because it was confusing where the serial was, and where the model was, but still it saved a lot of time.

3. Help us to identify the devices should barcodes or their analogs stickers. I chose the stickers on the basis that this solution would be less expensive and less time consuming (here I unfortunately lost it, because we all know that the cheaper the device, the less functions it has).

The DYMO Letra Tag + pair of cassettes was purchased (it is better to take paper tapes - plastic ones tend to peel off over time).

From the advantages it can be noted that it is quite portable and intuitive to manage.

Of the minuses - the lack of the English layout, there is no possibility of automatic numbering of stickers.

that's how he looks

cassette is inserted

! 6! AA batteries - printed about 3000 stickers (should be enough for the same amount)

here is an example of a finished sticker

As a result, we have already prepared a table with information provided by users + collected by us, it remains only to number the equipment. Next, print your list and stickers to them. I printed the stickers in two rows. Top DEV-TYPE Bottom of his ID. After that, a rather laborious process of pasting and deleting from the list of already pasted devices.

It is also necessary to create a pivot table, since It is not very convenient to read a table of 200-300 positions for all devices. With this we can use the function already built into Excel. Insert -> Pivot Table.

The following is an example of how to create a simple summary table, with the output of information on the number of equipment on projects

A small nuance, when adding new equipment, the pivot table needs to be re-created.

findings

- You need to think in advance what aspects you want to reflect in the inventory.

- A notebook with a list of equipment will take you when you have no more than 20 devices (IMHO).

- Label printer need to take more functional.

- Try to delegate part of the task to speed up its execution.

- When a new equipment appears, do not postpone its listing tomorrow (because tomorrow there will be new tasks, there is a great chance to forget about it).

Ps. I apologize in advance for the quality of the photos (phone camera).

Pss. I'm not sure that I picked the blog correctly. Where to transfer advise?

Source: https://habr.com/ru/post/113289/

All Articles