Motherboard production

Gigabyte Technology has just given reporters a tour of their factory in Taiwan in order to give a brief overview of the company, as well as show the work of their factories. Writing a review of a company is a boring and not fascinating business, so I suggest looking at the entire production cycle of a company's motherboards.

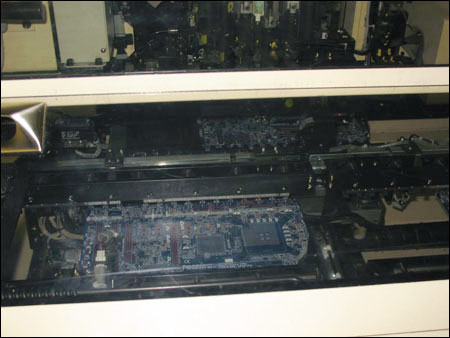

This is what a conveyor line looks like - why it is located behind glass, you can read more ...

On conveyor lines, everything should be as clean as in hospitals - that is why they are located behind glass. All workers are required to wear special gowns, gloves, and boot covers on their feet - the journalists got off with boot covers only :) By the way, the photo shows an air shower to get rid of all the dust before entering the conveyor line.

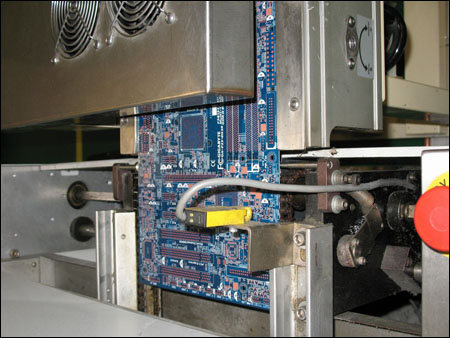

Production of motherboards begins with surface mounting - “sticking” various chips to PCBs (from printed circuit boards). The photo shows an automatic machine for applying solder paste on a PCB.

')

The newly printed board is ready for further testing :) Passing along a conveyor belt, various chips are applied to the board.

By the way, the chips are delivered to Gigabyte by various companies in the form of tapes.

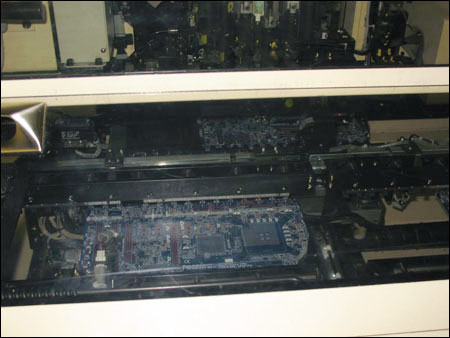

But the personification of progress - the SMD High Speed Mounter - accurately and quickly (~ 10 pcs / s) mounts different elements on the board:

But despite the accuracy of all operations, it is impossible to do without verification - all of a sudden, the technology has done something wrong. However, the visual control will be carried out, kx-m, also a technique :)

After passing the line with the installation automata, the boards enter the furnace (notice the name?), Where they are heated (~ 200 ° C) and the elements installed on the board are soldered.

Now the laborious process has begun. After the glue hardens, the boards for the absence of defects are checked by the controllers (~ 99% of women) manually ...

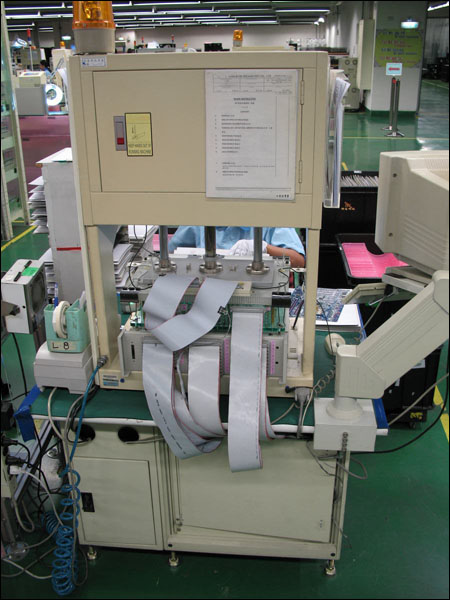

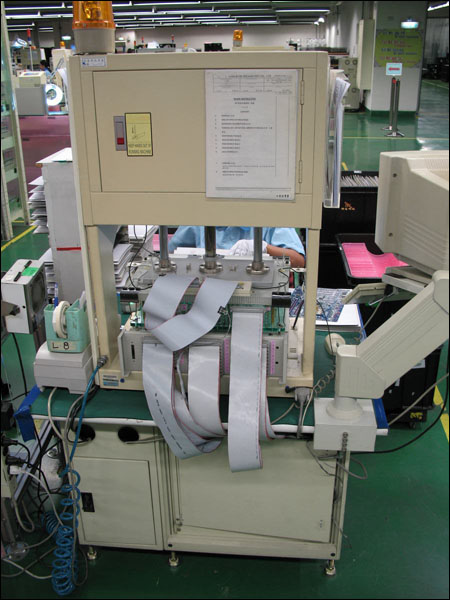

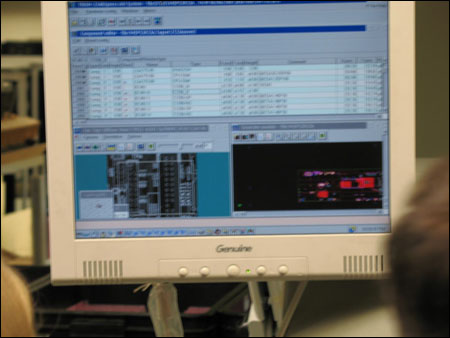

After checking "by eye" begins a series of automated tests for the performance of the boards.

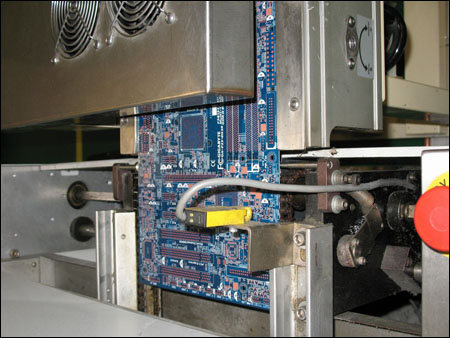

Another, final, automated verification of the location of the elements - after this procedure, the board will go to another floor, where the final assembly process will take place.

Again, some details complement women's hands ... By the way, have you noticed that jobs are located far from each other? Yes, you can not communicate here :(

Everything, now the motherboard is similar to our usual product:

And this man connects various connectors to the board:

Left just a little bit…

For making a presentation, you just need to polish the board so that no one gets hurt ...

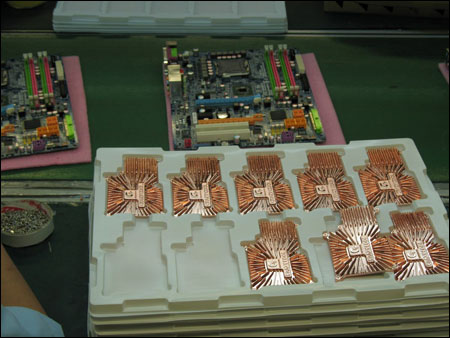

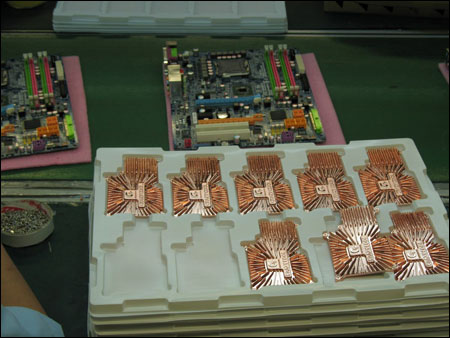

... and screw the radiator to the board:

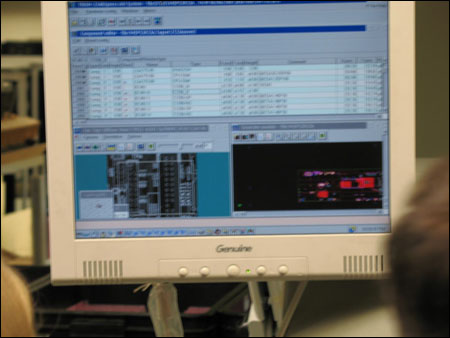

The board is ready and it remains to check ... for the last time:

Yes, the motherboard passed the test. Now they give it a marketable appearance (they are packed, packaged with loops, driver disks, etc.):

Well, then these same motherboards fall into our hands ... :)

via ExtremeTech .

This is what a conveyor line looks like - why it is located behind glass, you can read more ...

On conveyor lines, everything should be as clean as in hospitals - that is why they are located behind glass. All workers are required to wear special gowns, gloves, and boot covers on their feet - the journalists got off with boot covers only :) By the way, the photo shows an air shower to get rid of all the dust before entering the conveyor line.

Production of motherboards begins with surface mounting - “sticking” various chips to PCBs (from printed circuit boards). The photo shows an automatic machine for applying solder paste on a PCB.

')

The newly printed board is ready for further testing :) Passing along a conveyor belt, various chips are applied to the board.

By the way, the chips are delivered to Gigabyte by various companies in the form of tapes.

But the personification of progress - the SMD High Speed Mounter - accurately and quickly (~ 10 pcs / s) mounts different elements on the board:

But despite the accuracy of all operations, it is impossible to do without verification - all of a sudden, the technology has done something wrong. However, the visual control will be carried out, kx-m, also a technique :)

After passing the line with the installation automata, the boards enter the furnace (notice the name?), Where they are heated (~ 200 ° C) and the elements installed on the board are soldered.

Now the laborious process has begun. After the glue hardens, the boards for the absence of defects are checked by the controllers (~ 99% of women) manually ...

After checking "by eye" begins a series of automated tests for the performance of the boards.

Another, final, automated verification of the location of the elements - after this procedure, the board will go to another floor, where the final assembly process will take place.

Again, some details complement women's hands ... By the way, have you noticed that jobs are located far from each other? Yes, you can not communicate here :(

Everything, now the motherboard is similar to our usual product:

And this man connects various connectors to the board:

Left just a little bit…

For making a presentation, you just need to polish the board so that no one gets hurt ...

... and screw the radiator to the board:

The board is ready and it remains to check ... for the last time:

Yes, the motherboard passed the test. Now they give it a marketable appearance (they are packed, packaged with loops, driver disks, etc.):

Well, then these same motherboards fall into our hands ... :)

via ExtremeTech .

Source: https://habr.com/ru/post/10831/

All Articles