Sir, your liver is ready: behind the scenes of bioprinting

BioPrinting Organ Printing

In the near future, SAN DIEGO is going to say goodbye to the institution of donation and queues for donor organs. The biotechnology firm has created a printer that prints vessels using the patient’s own cells. Theoretically, in the future, the device will be able to print entire organs.

“We are now successfully printing blood vessels,” says Ben Shepherd, lead researcher at Organovo , which deals with regenerative medicine. “This week we have printed ten, and so far we are still exploring the conditions that will be best for durable vessels.”

Most of the organs of the human body include vessels in their structure, so the ability to print vascularized tissue is an important structural element for printing the whole organ. The printed vessels are already ready for testing on animals, and later - for testing on humans. If everything goes well, after a few years we will have the opportunity to replace the damaged vessel (for example, in the case of frequent injections during chemotherapy) with a new one, which was individually printed from a culture of cells taken from the patient’s body.

Problems in the way of printing a complete whole body are not only technological. The costs of developing, testing, manufacturing, and selling the first machine for printing organs will be hundreds of millions of dollars, not to mention the difficulties that companies will face in obtaining regulatory approval, such as the FDA.

“If Organovo is able to raise enough money, this company has a chance to succeed as the first bioprinting company. But time will tell, ”Dr. Vladimir Mironov, head of the advanced tissue fabrication department of the Medical University of South Carolina.

Organovo turned to the Wired.com service to cover the main stages used for printing blood vessels on a bioprinter.

Let's look at the process in more detail:

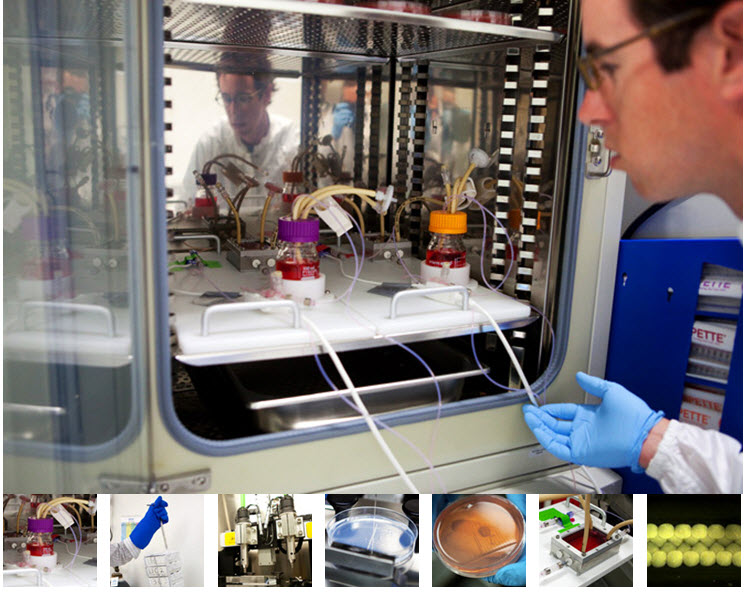

Bioreactor

Chief researcher Ben Shepherd places the bioreactor inside an incubator, where the growth medium will be supplied with a special pump for several days. The bioreactor uses a growth medium consisting of a special mixture of biochemical components. Its properties are selected in such a way as to most accurately reproduce the real environment that surrounds the growing cells in the body. It helps cells become durable vascular tissue.

Stem cells

Shepherd removes stem cells from a vessel with liquid nitrogen. Cells need to be cultivated for some time in order to significantly increase their number before downloading them to the printer. Stem cells are undifferentiated cells, which can later be modified into the necessary cell types. In principle, these cells can be taken from many parts of the patient's body - adipose tissue, bone marrow, skin cells - and make them a functioning vessel.

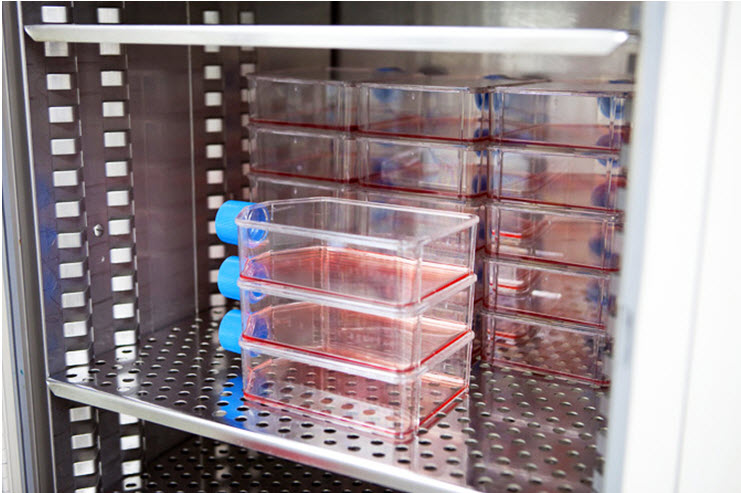

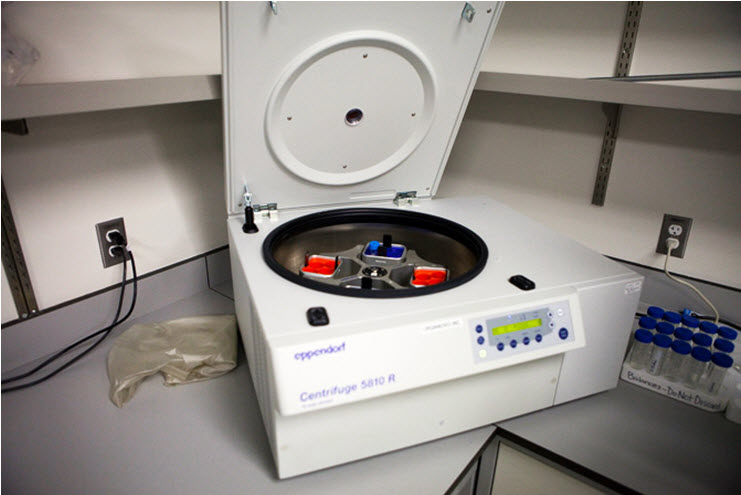

After the cells have been thawed, they are cultured in growth solution (top). Here, cells can divide and grow, which will further make it possible to use them for the formation of vessels. The solution also contains special additives (growth factors) that tell the cells what type of cells they need to become in the future. In this case, the cells of the blood vessels. After the required number of cells has been grown, they are separated from the growth solution using a centrifuge (bottom) and packaged into pallets for a printer.

')

Creating the required form of hydrogel

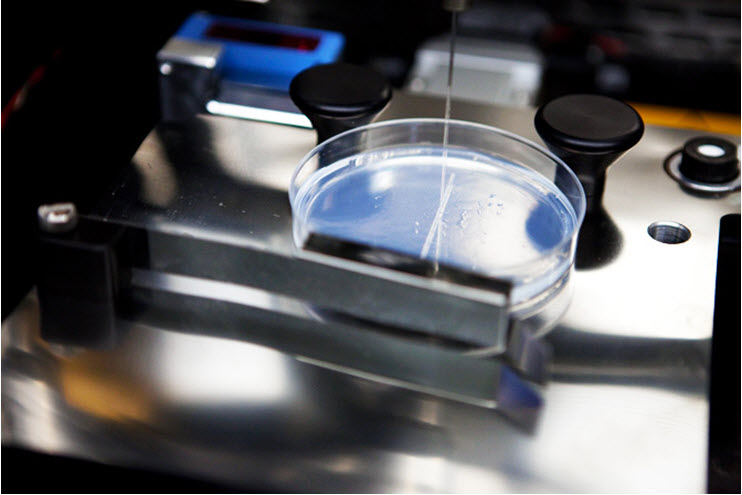

The first step in the printing process is to base a special material, the so-called hydrogel, which is used to temporarily create the necessary shape to maintain the tissue of the blood vessel.

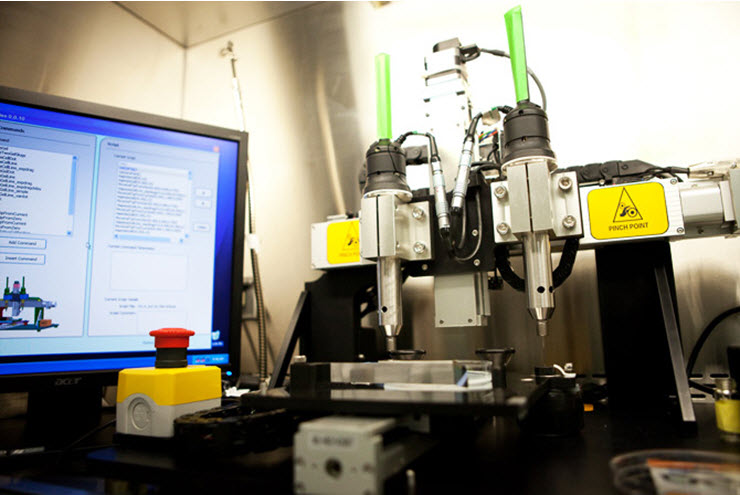

A specially designed printer uses two inkjet heads, which form the structure of the future vessel on the surface of the hydrogel in a Petri dish. The printheads are controlled by an automatic drive with microscopic precision. One of the heads is charged with biomass of cells, the second - with hydrogel.

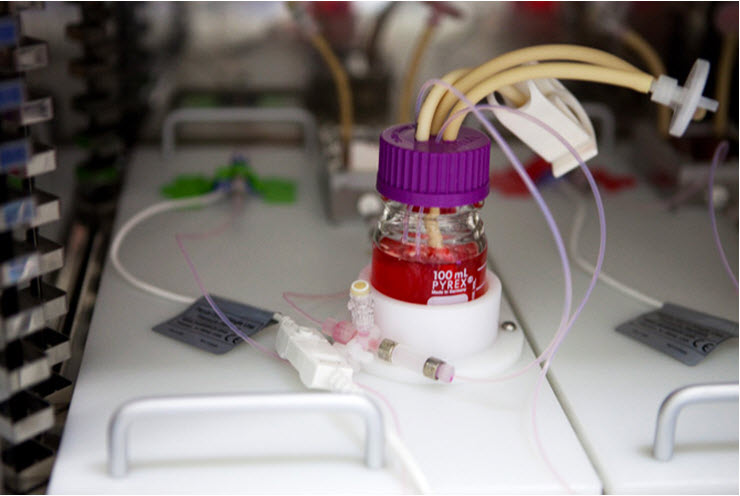

The chamber, called a bioreactor, is used to create the structure of the vessel and is harvested before the vessels are printed. A bioreactor is a fairly standard sample of a biotechnological apparatus. It is made from a sheet of aluminum in which a plastic container with various openings is placed. These holes are used to inject chemical solutions that will be used to feed growing vessels.

Before you start printing vessels, pallets with cultured cells are placed in the printer, like cartridges for printing with biomass instead of regular ink.

Blood vessel formation with hydrogel

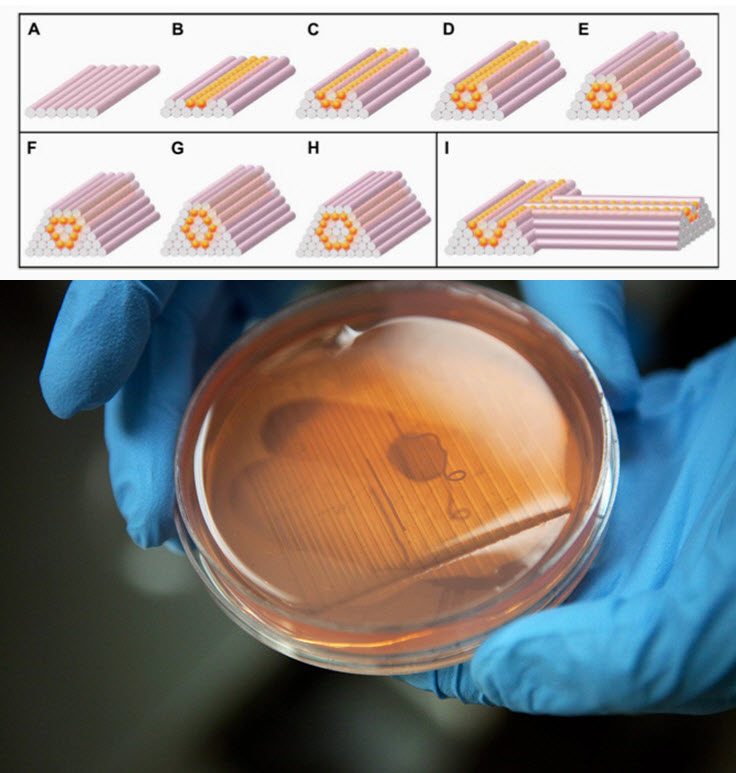

Thin strips of hydrogel are superimposed parallel to the surface of the Petri dish, after which the grooves formed in this way are filled with biomass of pallet cells. Further, another strip of hydrogel is printed in the middle of the strip of cells for the further formation of the cavity inside the future vessel.

Vascular cultivation

In the future, vessels printed in this way are alternately placed for several weeks in different growth media. After that, the cells are cleared of hydrogel. As a result, hollow tubules are formed from blood vessel cells.

The resulting tubules from the cells are placed in the bioreactor. The bioreactor (top) is pumped with a pump using special solutions (below) through the printed vessels. In such conditions, cells are transformed into real, strong vessels, with characteristics similar to intact vessels.

Final stage

After staying in the bioreactor, the printed cells grow together and form vessels, which can later be implanted into the patient. Since the vessels were grown from the patient's own cells, they are much easier for the body to perceive.

(based on publication: link )

Source: https://habr.com/ru/post/101667/

All Articles